In modern manufacturing and high‑performance industries, the material you choose can make or break your product’s performance. Among the most versatile and widely trusted options is 316L Stainless Steel Foils — a low‑carbon stainless steel variant engineered for superior corrosion resistance and reliability under extreme conditions.

Unlike standard stainless steel grades, 316L offers an ideal balance of flexibility, strength, and chemical stability. Across sectors like chemical processing, aerospace, medical devices, and renewable energy, this alloy has become a go‑to material where exceptional quality is essential.

In this guide, we’ll explore what sets 316L Stainless Steel Foils apart, why its low carbon content matters, its real‑world applications, and how it compares with other stainless steels. Whether you’re a materials engineer, manufacturer, or curious reader, this article will help you make informed decisions backed by factual data and industry insight.

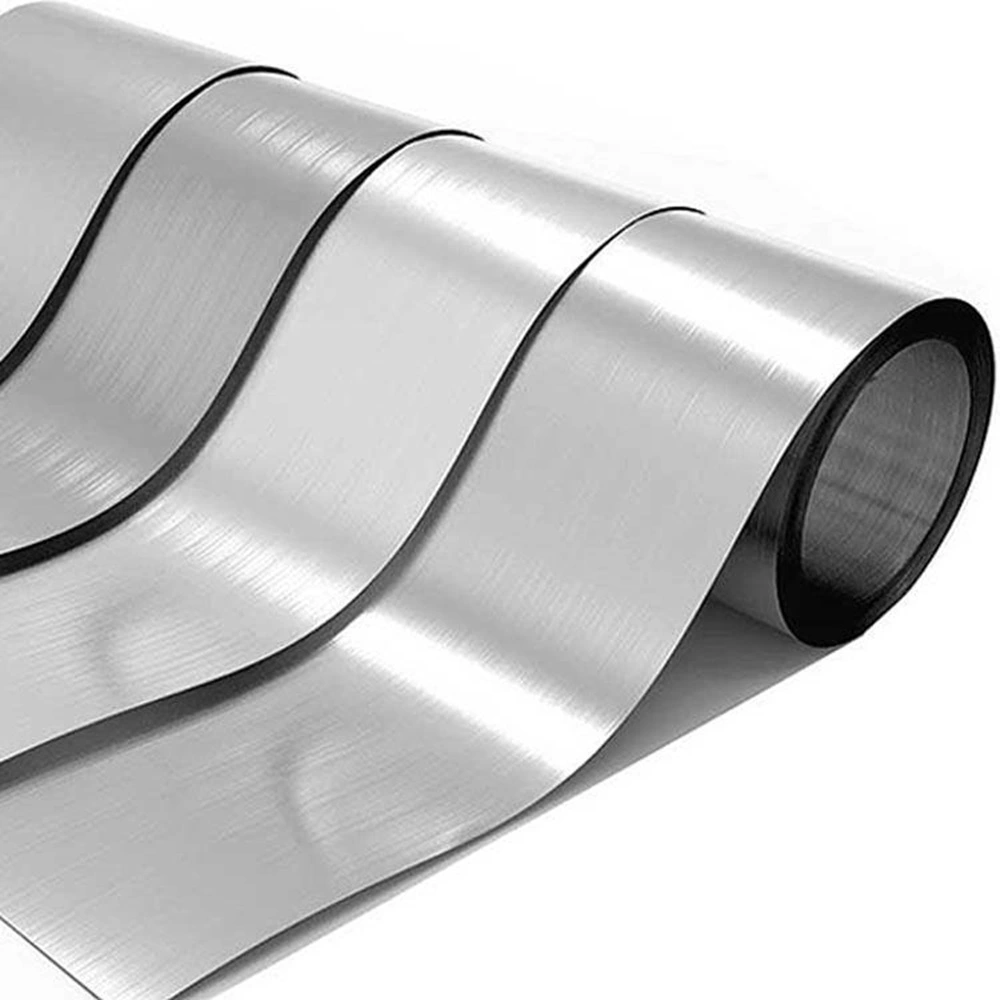

What Is 316L Stainless Steel Foil?

316L stainless steel foil is an ultra‑thin sheet of corrosion‑resistant alloy comprising primarily iron, chromium (16–18%), nickel (10–14%), and molybdenum (2–3%). The “L” designation means it has lower carbon content (≤ 0.03%) compared to standard 316 grade, which provides tangible advantages for welding and chemical exposure.

Understanding this alloy’s composition helps explain its standout properties. The addition of molybdenum, for example, significantly enhances resistance against chlorides and acidic environments — making it vastly more resilient than 304 stainless steel.

You can explore related stainless steel materials and uses in the comprehensive guide on Stainless Steel Coil Consumer Goods Types & Uses.

Why the “L” Matters: The Role of Low Carbon in Performance

One of the most compelling features of 316L Stainless Steel Foil is its low carbon content. But why does this matter?

Reduced Sensitization

During welding or high‑temperature service, carbon can combine with chromium to form carbides at grain boundaries. This process, called sensitization, depletes chromium at the surface and compromises corrosion resistance. Lowering carbon content helps maintain the protective chromium layer, preventing corrosion in the weld zone.

Improved Weldability

The low carbon content makes 316L far more weldable than regular 316. For many high‑precision assemblies or thin foil applications, ease of welding can directly impact manufacturing efficiency and material reliability.

Greater Corrosion Resistance

316L’s corrosion resistance is one of its most prized attributes. It performs exceptionally well against chlorides and industrial chemicals, which is why it’s trusted in environments that are highly corrosive or exposed to saline conditions. You can learn more about performance differences in our 316 vs 316L Stainless Steel Strip resource.

316L Stainless Steel Foil vs. Other Alloys

Comparisons help highlight why 316L often stands out:

| Property | 304 Stainless Steel | 316 Stainless Steel | 316L Stainless Steel |

|---|---|---|---|

| Corrosion Resistance | Good | Better | Best (especially in chlorides) |

| Carbon Content | ~0.08% | ~0.08% | ≤ 0.03% |

| Weldability | Moderate | Moderate | Excellent |

| Cost | Lowest | Mid | Higher (but worth it) |

| Typical Use Cases | Kitchenware, Appliances | Marine, Chemical | High‑end, corrosive environments |

While 304 is popular for everyday use, 316 and especially 316L Stainless Steel Foil outperform it where extreme conditions are involved.

Key Properties of 316L Stainless Steel Foil

316L Stainless Steel Foils is prized for a unique blend of mechanical and chemical properties:

Corrosion Resistance

Because of its composition (especially molybdenum and chromium), 316L Stainless Steel stands up to sea water, industrial solvents, and chloride‑rich environments much better than other grades. This is a major reason it’s preferred in coastal, marine, and chemical process settings.

High Tensile Strength and Durability

Even in thin sheet form, 316L maintains robust mechanical strength. This is vital for applications where structural integrity cannot be compromised.

Temperature Tolerance

316L performs well over a wide temperature range. It stays stable under both cryogenic conditions and moderate heat — making it ideal for heat‑exchanger components or thermal shielding applications.

For a deeper look at how this foil is manufactured specifically for heat treating, see Manufacture Ultrathin 316L Stainless Steel Foil for Heat Treating.

Applications of 316L Stainless Steel Foil

The combination of corrosion resistance and formability makes this metal foil truly versatile. Below are key industries and uses:

Chemical Processing Equipment

In chemical plants, exposure to acids and aggressive agents is routine. 316L Stainless Steel Foil is used for gasket material, liners, and protective shielding because it resists pitting and crevice corrosion in these harsh environments.

Medical and Pharmaceutical Devices

This alloy is biocompatible, easy to sterilize, and resists corrosion from bodily fluids — making it a favorite for surgical instruments, implantable devices, and laboratory equipment.

Aerospace Components

Weight and performance are critical. The high strength‑to‑weight ratio of thin 316L foil combined with its oxidation resistance makes it suitable for thermal insulation, coatings, and vibration dampening layers in aerospace assemblies.

Renewable Energy and Infrastructure

From solar thermal systems to energy storage, renewable technologies rely on durable materials that can withstand varying climates and corrosive exposures. Read more about these applications in Stainless Steel Coil Renewable Infrastructure.

Consumer & Industrial Goods

Even everyday products benefit from the qualities of 316L. Think premium cookware, high‑end architectural fixtures, or precision measuring tools — all built for longevity and reliability.

Manufacturing Process: How 316L Stainless Steel Foil Is Made

Creating high‑quality stainless steel foil requires precision and control. The production process combines casting, cold rolling, annealing, and finishing steps. The goal is to produce consistently thin material without breaking or compromising mechanical integrity.

The general steps include:

- Melting & Casting: Alloy elements are melted together and cast into slabs.

- Hot Rolling: Slabs are heated and reduced in thickness.

- Cold Rolling: Further thinning occurs at room temperature for enhanced strength.

- Annealing: Heat treatment restores ductility after cold work.

- Surface Finishing: Polished or treated for specific end‑use requirements.

For a full walkthrough of stainless steel coil production, visit Stainless Steel Coil Production Process Guide.

Performance Benefits in Real‑World Scenarios

The true value of 316L Stainless Steel Foil becomes clear when compared with alternate materials under real conditions:

Marine & Coastal Environments

Salt spray testing shows 316L far outperforms 304 in chloride exposure, resisting pitting corrosion that quickly damages weaker stainless steels. This makes it essential for components in ships, oil platforms, and coastal installations.

High‑Temperature Chemical Exposure

316L maintains strength and structure in environments that reach above typical room temperatures. Chemical exposure plus elevated heat can accelerate corrosion in many alloys — but 316L retains its integrity far longer.

Biomedical Sterilization Repeated Cycles

Repeated autoclaving at high pressure and steam temperatures can degrade many materials. Yet, 316L’s corrosion resistance and low carbon content prevent embrittlement and sustain surface finish over repeated cycles.

Choosing the Right 316L Stainless Steel Foil for Your Project

Selecting the type and thickness of foil depends on your application demands. Consider:

- Thickness & Tolerance: Foils range from extremely thin gauges to heavier sheets. Choose based on flexibility and strength requirements.

- Surface Finish: Mill finish, polished, or specialty textures can affect corrosion resistance and visual quality.

- Certification Standards: Verify material certifications (ASTM, ISO) to ensure compliance with industry needs.

Explore available material options at Stainless Steel Foil Products or check specific products like the 316 Stainless Steel Coil.

Sustainability & Lifecycle Considerations

316L stainless steels are highly recyclable. Industry data shows that stainless steel recycling rates often exceed 80% globally, reducing environmental impact compared to many other alloys.

Because 316L resists corrosion and requires less frequent replacement, lifecycle costs and waste are typically lower — a key benefit for sustainable manufacturing.

Summry

316L Stainless Steel Foil is a high‑performance material that delivers improved corrosion resistance, better weldability, and enhanced durability compared with other stainless steel options. Its lower carbon content provides real advantages in critical industrial, medical, and engineering applications.

By choosing 316L stainless steel foil for demanding environments, manufacturers and designers gain a material that’s reliable, long‑lasting, and capable of exceeding expectations under stress.

Explore material options, technical guides, and product specifications further on Stainless Steel Foil to find the right solution for your project.

FAQs

What makes 316L Stainless Steel Foil better for corrosion resistance?

Answer: 316L Stainless Steel Foil contains molybdenum and lower carbon content, which significantly enhances resistance to chlorides, acids, and corrosive environments compared to many other stainless steels.

Is 316L Stainless Steel Foil suitable for welding applications?

Answer: Yes — the low carbon content in 316L Stainless_Steel Foil minimizes sensitization during welding, making it highly suitable for welded assemblies without losing corrosion resistance.

Can 316L Stainless Steel Foil be used in food and medical equipment?

Answer: Absolutely. 316L Stainless Steel Foil is biocompatible and corrosion‑resistant, ideal for medical devices and food processing equipment where hygiene and durability are essential.

How does 316L Stainless Steel Foil compare to 304 stainless?

Answer: 316L Stainless Steel Foil offers superior corrosion resistance, especially in chloride environments, whereas 304 is more basic and less resistant to harsh chemical exposure.

Does 316L Stainless Steel_Foil resist high temperatures?

Answer: Yes. 316L Stainless Steel Foils maintains its mechanical properties and structural stability across a broad temperature range, making it suited for heat exchanger and industrial applications.

Is 316L Stainless Steel Foil environmentally sustainable?

Answer: Yes — 316L Stainless Steel Foils is highly recyclable and offers long service life, reducing disposal and replacement impacts compared to less durable materials.