A Complete Guide to 316 Stainless Steel Plate

Ewan Liao

The 316 Stainless Steel Plate is a premium austenitic stainless steel product renowned for its exceptional corrosion resistance, strength, and durability. Containing molybdenum, the 316 stainless steel plate offers enhanced resistance to pitting and crevice corrosion in chloride environments, making it ideal for use in harsh conditions such as marine applications, chemical processing, and medical devices.

Material Testing After You Place An Stainless Steel Foil Order

Hardness Testing

Ingredient detection

Tensile Strength Test

Table of Contents

What Is the 316 Stainless Steel Plate?

The 316 Stainless Steel Plate is a flat-rolled product made from grade 316 stainless steel, an alloy composed primarily of iron, chromium, nickel, and molybdenum. This composition provides a combination of high strength, excellent formability, and superior corrosion resistance, particularly against chlorides and other industrial solvents.

As part of the 300 series of stainless steels, the 316 SS plate is characterized by its austenitic microstructure, offering excellent mechanical properties and high toughness. The addition of molybdenum distinguishes it from grade 304, enhancing its corrosion resistance and making it suitable for more demanding applications.

Strength of 316 Stainless Steel Plate

The 316 Stainless Steel Plate exhibits impressive mechanical strength. It has a tensile strength of approximately 515 MPa (75 ksi) and a yield strength of around 205 MPa (30 ksi). This robust strength, coupled with its ability to maintain mechanical properties at elevated temperatures, makes it a reliable material for structural and high-pressure applications.

Features of 316 Stainless Steel Plate

Key features of the 316 stainless plate include:

- Superior Corrosion Resistance: Enhanced resistance to pitting and crevice corrosion due to the addition of molybdenum.

- High Temperature Performance: Retains strength and toughness at high temperatures.

- Excellent Formability and Weldability: Easily fabricated and welded, suitable for complex shapes.

- Hygienic Properties: Smooth surface finish suitable for hygienic environments like food processing and medical equipment.

Technical Parameters of 316 Stainless Steel Plate

Understanding the technical parameters is crucial for proper application:

- Thickness Range: Available in various thicknesses, the standard 316 stainless steel plate thickness ranges from 0.5mm to 100mm, including options like 10mm 316 stainless steel plate.

- Standard Specifications: Compliant with standards such as ASTM A240.

- Mechanical Properties: Tensile strength, yield strength, elongation, and hardness values are critical for design considerations.

- Surface Finish: Available in finishes ranging from mill finish to polished surfaces for aesthetic or hygienic purposes.

Applications of 316 Stainless Steel Plate

The versatility of the 316 stainless plate allows it to be used in a wide range of applications:

- Marine Equipment: Ideal for shipbuilding, offshore platforms, and coastal facilities due to its resistance to seawater corrosion.

- Chemical Processing Equipment: Used in tanks, valves, and pipelines handling corrosive chemicals.

- Medical Devices: Commonly used in surgical instruments and implants because of its biocompatibility.

- Food Processing Equipment: Preferred material for equipment requiring high hygiene standards.

Chemical Composition of 316 Stainless Steel Plate

The typical chemical composition of the 316 stainless steel plate is:

- Chromium (Cr): 16.0 – 18.0%

- Nickel (Ni): 10.0 – 14.0%

- Molybdenum (Mo): 2.0 – 3.0%

- Carbon (C): ≤ 0.08%

- Manganese (Mn): ≤ 2.0%

- Silicon (Si): ≤ 1.0%

- Phosphorus (P): ≤ 0.045%

- Sulfur (S): ≤ 0.03%

Are 316 and 316L Stainless Steel Plates Interchangeable?

While 316 and 316L stainless steel plates are similar, they are not entirely interchangeable. The primary difference lies in their carbon content: 316L has a maximum carbon content of 0.03%, compared to 0.08% in 316. The lower carbon content in 316L reduces the risk of carbide precipitation during welding, which can lead to intergranular corrosion. Therefore, 316L stainless steel plate, or 316L plate, is often preferred in welding applications to ensure optimal corrosion resistance.

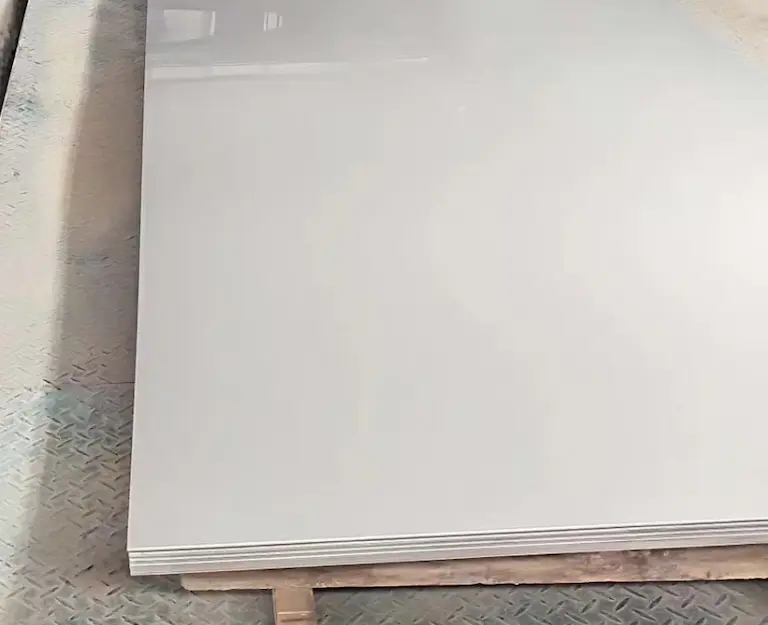

316 Stainless Steel Plate Finishes

Besides, plates can be further cold rolled up to a 2D finish when smoothness and uniformity are required. Sheet & Plate standard lengths (in mm) include: 2000, 2500, 3000 and 6000. 1000, 1250. 1500 & 2000 are standard widths (in mm).

Once the thickness of stainless steel exceeds 6 mm, we call it plate metal. It is in use in applications with primary considerations of longevity and power. This involves the parts of a building in which a great deal of weight is with the support of metal. In these applications, too, the infinite steel bar is also in use. In the automotive industry where reliability and strength are in requirement for the car to pass crash tests, 316 stainless steel plate is often in use extensively.

Moreover, the only distinction between the plating of stainless steel and the plating of stainless steel is the spreading thickness of the metal and the applications that are on the list by the application of both forms. Plates are also in use in aviation and transport industries in addition to vehicle manufacture and provide structural parts for ships, military vehicles, ferries, and trucks.

On the other hand, sheets are popular in cookware and other household appliances and are also popular for making car license plates and the light bulb foundation.

Read more about A Complete Guide to SUS Stainless Steel Banding

Will a 20 mm thick 316 stainless steel plate roll on a roll, so that a 16 mm thick stainless steel plate can roll off it?

If the machine manages 16mm MS, when you are speaking to a three-roller plate bender, then 8mm or even 10mm is the place to start the test. Stainless is tougher than a mild plate of steel such as 43A. It’s more difficult than the next toughest commonly used MS, 50B.

Thus, there might be a stainless grade that is softer than MS, but I’ve never used it. It’s all a lot harder than MS in the 300 Series. There is also a hard work problem with stainless steel so that multiple passes can become more difficult.

Before beginning, it is essential to seriously clean the roller surfaces, or the metal corrosion on them ruins the stainless surface. The rolling plates and parts of 3mm and 4mm SS316 or 304 are a standard shipbuilding operation. Specialized information is likely to be thicker than that.

Can the resistance welding methods of mild steel and 316 stainless steel plates be soiled?

The only way to detect a sound spot welding is via the “peel test.” Do not depend on an approach that looks strong, the weld might look fine but it’s very poor. Please take care to properly set the solder spot.

Therefore, the peel test involves splitting one part of your test sheet into a vice and trying to remove the other section by whatever means. When the blade has been peeled out, you know you made a good spot weld. When you end up with a solder button.

How can you apply mild steel and welded plates to stainless steel?

For the soldering of 316 stainless steel plates with MS plates, almost all welding techniques can be in use. The most frequent are SMAW, GMAW (MIG), and GTAW (Stick Electrode Welding) (TIG).

The manufacturing scale and availability can be on selection according to quality requirements. The electrode/consumption, in any case, refers to the 316 stainless steel plate.

What power range and laser form do the 25,000 holes need to be pierced into a 35-mile (.89-mm) thickness stainless steel sheet with 20milOD (0.5mm)?

Many variables are on consideration in the processing of laser materials since the laser energy is pure radiation and hence many variables depend on the interaction between laser and material.

Also, surface reflection is a big player in laser wavelength, and aluminum is highly reflective, requiring more power than you might intuitively believe you could have to use the same or even more laser power to cut the steel’s same thickness.

Therefore, it should be about 0.5 mm to pierce a 0.5 mm beam if you could achieve a sharp 0.5 mm laser focal lens. A pressure gas jet must be in use to aid in a clean pierce.

How do you measure the weight of a 300 mm diameter and 5 mm thick circular 316 stainless steel plate?

First, calculate the steel plate volume. This is the circular lateral region of 5 mm. PI*R***2 is the region of a circle. The radius is half as much as 150 mm in diameter. This creates a cubic mm volume.

Then, you now have your response and multiply the volume with the density of stainless steel. The density of ordinary materials, such as steel, and expect the stainless steel density to be very similar to the stainless steel density.