In recent years, people have used stainless steel banding in more and more places.

If you are a communication engineering installation team, you probably need to use a stainless steel banding to strengthen the connection between the equipment and the long pole. This reinforcement device will make your equipment more reliable, and will not fall from a high altitude due to problems such as rust and corrosion, which will endanger safety.

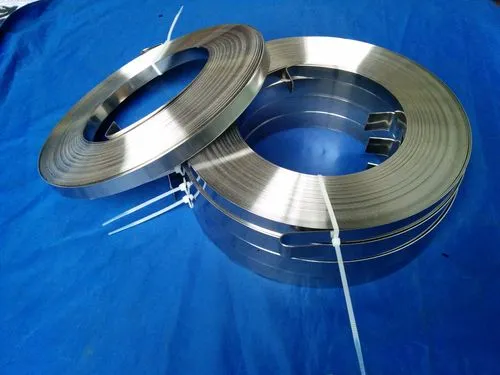

The following is a detailed introduction of the cost-effective stainless steel band.

Myriad Stainless Steel is a high-quality stainless steel supplier and wholesales 304 stainless steel band to the United States. Yaoyi tainless steel band. Suppliers have won the support of users with extremely high-quality products and thoughtful after-sales service. Provide a strong supply chain for your stainless steel band wholesale and retail business. Support 304 stainless steel band and 201 stainless steel band for fast delivery.

Steel contains 11% or more chrome, which is naturally resistant to corrosion. This shirt is intended to withstand both heat and sunlight. You can count on stainless steel bands to keep your things safe and secure no matter what the weather is like. The best way to move large, hard, and sharp objects over long distances is with stainless steel strapping.

Connected to this, various strapping materials that are used to transport products have their tensile strength measured. The engineering unit used to quantify a material’s maximum load is a term used to describe it as durable.

Tensile strength is the greatest in stainless steel brazing. Because banding should prevent items with sharp edges from cutting through the strapping, soft banding is not recommended. For materials that do not settle, soft banding is unsuitable.

Stainless steel banding, also known as stainless steel strapping or stainless steel band, is a versatile material used for securing, bundling, and packaging various items. It is commonly used in industries such as construction, manufacturing, shipping, and telecommunications. Stainless steel banding offers exceptional strength, durability, and resistance to corrosion, making it suitable for both indoor and outdoor applications.

The banding is made from different widths and thicknesses of steel alloys, typically ranging from 1/4 inch to 3/4 inch in width and 0.015 inch to 0.044 inch in thickness. It is available in different grades, each with its own unique properties and applications.

Stainless steel banding offers numerous advantages that make it a favored choice in various industries. Some of the key advantages include:

Due to its advantageous properties, stainless steel banding finds extensive use in various applications, including:

Stainless steel banding is available in different grades, each offering specific advantages and suitability for various applications. The most common grades include:

Stainless steel banding is available in a range of widths and thicknesses to suit different bundling and fastening needs. Common widths include 1/4 inch, 3/8 inch, 1/2 inch, 5/8 inch, and 3/4 inch. Thicknesses typically range from 0.015 inch to 0.044 inch.

The choice of stainless steel banding depends on the specific application and requirements. For general-purpose bundling and securing, 201 or 304 grade stainless steel banding is often suitable. In marine or chloride-rich environments, 316L grade stainless steel banding is recommended for its superior corrosion resistance.

Stainless steel banding is used in a wide range of applications across various industries. Some popular uses include:

To ensure proper installation and usage of stainless steel banding, various specialized tools and accessories are available. Some commonly used tools include:

The selection of appropriate tools and accessories depends on the specific application and the type of stainless steel banding being used.

In this section, we will address some frequently asked questions about stainless steel banding:

Yes, stainless steel banding is highly suitable for outdoor use due to its excellent corrosion resistance. It can withstand exposure to sunlight, moisture, and temperature variations without deteriorating.

Yes, stainless steel banding can be easily cut using banding cutters and shaped using appropriate tools. It provides flexibility in accommodating various shapes and sizes of objects.

Stainless steel banding offers secure and reliable cable management by effectively holding cables in place, reducing the risk of tangling, and allowing for organized and neat installations.

Stainless steel banding is typically designed for one-time use, especially when using crimping tools or utilizing stainless steel buckles and clips for secure fastening. However, it can be cut and removed if necessary for readjustments or replacements.

Yes, the selection of banding widths and thicknesses depends on the specific application, bundle size, and the required level of strength and security. Thicker banding is generally used for heavier loads and applications that require higher strength.

In this comprehensive guide, we have covered the essential aspects of stainless steel banding, including its advantages, classifications, popular uses, and tools. Stainless steel banding’s strength, durability, and resistance to corrosion make it a reliable choice for bundling, securing, and organizing objects across various industries.

Stainless steel bands are made of a variety of widths and thicknesses of steel alloys, all of which can be utilized in various ways. The use of stainless steel serves the same purpose as using a belt to hold one object to another or as a method of keeping a stack of goods in place. As is the case with other industries, there is a strong possibility that your company will benefit from learning more about this form of banding.

Steel comes in all kinds of forms, such as alloys. There are only three options to choose from when purchasing stainless steel bands.

Their positions are listed as follows:

201 grade stainless steel

304 stainless steel

316L stainless steel

It is crucial to choose the correct band to achieve the desired outcomes, so let’s examine each one in detail.

Keep reading: A complete guide to AISI 303 Stainless Steel

Developed in response to nickel skyrocketing prices, Type 201 stainless steel is a one-of-a-kind product. Nickel concentration is lower, but it is also far less expensive. When there is less nickel, it is less effective at preventing corrosion. Levels of manganese in type 201 banding aid in the fact that it is one of the hardest stainless steel banding varieties.

Thus, industries that seek a greater level of durability while also having less concern for exposure to corrosive environments favor this type. This is most frequently used to attach signs and other signage to plumbing fixtures. It provides adequate corrosion protection, though it is not as corrosion-resistant. As a result, Type 201 stainless steel has great utility in cold climates.

To make up for the nickel shortage, the material has an extra amount of manganese and nitrogen. This seems to be the most sought-after type of stainless steel because it appears to be the least expensive. Even so, in severely corrosive environments, it will not last long.

Unlike stainless steel, this form of stainless steel has a higher nickel content, making it easier to tell apart from other forms of stainless steel. With the nickel price increasing, the cost of 304 stainless steel has increased. The nickel, in contrast, acts as a corrosion inhibitor for type 304. From an industrial perspective, it’s quite obvious why these styles have become popular with the appliance and plumbing industries. Additionally, it draws in businesses related to signs and electrical utility providers for the same reasons. Also commonly used for sign posts and strapping pipelines and tanks, is stainless steel banding of this type.

Type 304 has a lot to offer in contrast to Type 302. Type 201 is widely used in a variety of industries where corrosion, moisture, and other contaminants are a constant threat. Type 304 is a suitable option for connecting lightweight signage to metal poles, anchoring insulation to pipes, and numerous other applications.

Firms use type 304 steel banding because they are also exposed to corrosive elements. Other than its capability to change shape, type 201 stainless steel bends, shapes, and flattens like regular steel. Despite having higher corrosion resistance, the steel is less durable than other types. Stainless steel has different advantages and disadvantages for each variety. When needed, they are well-suited to the conditions.

Read more:A complete guide to AISI 304L Stainless Steel

Type 316 has the greatest corrosion resistance among the three types. The nickel content is no surprise. Type 316 stainless steel banding has the highest nickel content, and so it is the most expensive.

Many industries, however, find the expense to be justifiable. Type 316 contains molybdenum, which is corrosion-resistant. Type 316 stainless steel is suitable for use in salty or chloride-rich environments. In terms of cost effectiveness, type 304 stainless steel does appear to be a better option, but it is significantly weaker to both salt and chloride. This makes it break down more quickly, so you will have to replace it more frequently in the long term. Type 316 stainless steel is the most popular choice for outdoor and coastal applications.

The grade must be heightened to handle the more extreme situations. Type 316 stainless steel has more chromium, making it more durable. Besides molybdenum and chromium, other alloys, such as nickel, titanium, aluminum, copper, nitrogen, phosphorous, and selenium, are available.

Type 316 has several important features that help to make it one of the best grades of stainless steel. Stainless steel application is completely dependent on the type of stainless steel that is used. Not always economical to use type 316 stainless steel when other options are available. In other cases, you will save money because of the higher price point.

Because type 316 steel is the most expensive steel available, yet it is also the most corrosion resistant, therefore, it is the most expensive type of steel that is available. It is also very resistant to temperatures of great severity. The most important reasons Type 316 is favored on oil rigs and in the marine industry are because of these two qualities.

The proper width and length of a stainless steel band is undetermined.

A wide variety of sizes and shapes are available for the stainless steel bands. It is due to the various applications that it has so many varied uses. The three primary alloy types discussed before have diameters ranging from 14 inches to two inches and from.015 inches to.044 inches thick.

Thickness and/or thickness of steel bands correlates to the strength and pressure that it can bear.

On the other hand, however, these characteristics have a price to pay. Our first observation is that working with this much power will be challenging. There is no doubt that bending a thick slab of steel will be difficult. If you want to use the correct product for your application, then you must exercise extreme caution in your selection. Afterwards, use the appropriate tool for application.

Also, the price of stainless steel should be taken into consideration.

316 stainless steel bracelet (coated and uncoated) is an alloy that performs well in both freshwater and typical atmospheres. This item is non-magnetic, too. It’s well-suited for applications such as chemical, agricultural, marine, food, and splash zones, as well as for applications with a low pH.

Even if you have a stainless steel bracelet, you won’t benefit much. It is obvious that you will not tie the band together in the same manner as you would a ribbon or a rope. To close the circle, you’ll need a closure instead. Given the importance of this position, carefully consider the appropriate closure device.

Of the various tools you will require, these are the three main types:

To cut steel banding, you will need these tools. The type of bands you are using will determine which type you will need. Cutting equipment must be heavy to deal with heavy-duty steel. Once you have enough material for the job, you will need to trim the banding; afterwards, if there is still extra banding left over, you will need to apply closure.

When you use a closure, you are also employing tension. For obtaining good, tight banding, that’s how you do it. It would be nearly impossible to achieve on one’s own without this equipment.

Pusher seals require crimping tools when they are utilized.

Stainless steel banding is a great product because of its versatility and durability. This is great for higher-volume uses, since it has a very high breaking strength. Compared to other types of metal and plastic strapping, stainless steel basting has a stronger corrosion resistance, which means it will last longer in harsher conditions.

There are three distinct grades of Stainless Steel Banding; however, in the most difficult of conditions, there are multiple grades of Stainless Steel that perform better.

In addition, the different grades of stainless steel are made of either 201, 304, or 316 grade stainless steel; this grade is selected based on the intended application. The cost of maintenance and replacement can be reduced if products are secured underwater or indoors using Stainless Steel Strapping. Using our Stainless Steel Buckles and Clips as well as our Stainless Steel Strapping in various applications enhances the strength of every setup. In order to produce the best results, the Stainless Steel Buckles and Band must be the same size.

Try for free information about the A Complete Guide to AISI 321 Stainless Steel

Yaoyi is a well-known stainless steel bandmanufacturer. We keep innovating according to your needs, and continue to provide you with the most complete stainless steel band and its supporting tools.

With 25 years of stainless steel band wholesale and production experience, yaoyi stainless steel has trained many skilled workers. They can produce stainless steel bands promptly and quickly for you according to your needs. Complete raw material supply system and professional material laboratory ensure the best quality of stainless steel band.

Yaoyi is a well-known stainless steel band manufacturer. We keep innovating according to your needs, and continue to provide you with the most complete stainless steel band and its supporting tools.

With 25 years of stainless steel band wholesale and production experience, yaoyi stainless steel has trained many skilled workers. They can produce stainless steel bands promptly and quickly for you according to your needs. Complete raw material supply system and professional material laboratory ensure the best quality of stainless steel band.

Get it now:A complete guide to AISI 410 Stainless Steel

Our founder is YUE. Yue is an engineer with 39 years of experience in stainless steel production. He graduated from Northeastern University with a major in metallurgy. Since 1996, Yue led the team to create Yaoyi Stainless Steel Co., Ltd. The quality of products has always been Yaoyi’s highest priority. If you want to have professional stainless steel team support, just cooperate with us. Strong R&D capabilities and complete testing laboratories will bring beneficial quality assurance to your products.

In addition to the quality of the stainless steel band, a strong marketing team also plays an important role in our rapid development. Our professional and cohesive team has made great contributions to the continued success of yaoyi stainless steel. According to market demand, we have developed a variety of different types of stainless steel band packaging that meet market demand and complete its overall package.

We constantly update the styles of stainless steel band. Innovation and quality assurance are our company’s core competitiveness. Seize market opportunities for you and win huge profits. Different regions and different countries have different requirements for stainless steel bands. We provide you with stainless steel bands that suit the needs of various markets. It is difficult for you to find a reliable supplier, but if you find us, we will provide a strong guarantee for your sales.

Try for free AISI 4140 Low Alloy Steel

Fast delivery. We own a warehouse with fifty acres of land. If you want to buy 50 stainless steel bands, we can ship them directly from our inventory. If you need 100~1000 stainless steel bands, our delivery time is 15 days. If you need 1000~5000 stainless steel bands, our delivery time is 20 days.

Fast delivery time: We cooperate with UPS, DHL, FeDex, JAS, whether you need express delivery or container transportation, we can ensure that you arrive quickly, saving you valuable time.

Efficient after-sales service: We are a 24/7 sales and service team. If you have any questions about stainless steel band, you can contact us at any time. Solving problems for you in time is our constant pursuit.

There are many suppliers who provide very poor quality and easy to rust stainless steel band, because the price of one-time transaction is much lower. Many people cannot resist its low price temptation. This will cause you to lose your long-term users and hurt your reputation. We are different from other stainless steel bands. Other factories are just a stainless steel slitting factory. They do not have cold rolling technology and cannot be controlled from the source of the material, but we have our own technical equipment and laboratory to provide you with favorable quality assurance. .

Stainless steel banding is a popular choice for many industries due to its strength and durability. However, the cost of this banding can vary significantly depending on the source. In this article, we will provide a detailed breakdown of the different types of stainless steel banding and their prices.

There are various types of stainless steel banding available in the market. Let’s explore the most common types and their associated prices:

| Source | Price |

|---|---|

| Best Materials | $19.65 per box of 100 buckles |

| Amazon | $149.99 |

| Hose Warehouse | $27.92 |

| Cable Ties and More | Prices vary |

| Rax Industry | Prices not listed |

It is important to note that these prices are subject to change and may not be representative of all stainless steel banding available on the market. Additionally, there may be other factors to consider when purchasing banding, such as shipping costs and availability.

The bar chart above represents the price comparison of stainless steel banding from various sources. As seen from the chart, prices can range widely depending on the supplier.

There are several factors that can influence the price of stainless steel banding. These factors include:

Material: The quality and grade of stainless steel used can affect the pricing. Higher grade stainless steel generally comes at a higher cost.

Width and Thickness: The width and thickness of the banding can also impact the price. Thicker and wider bands may be more expensive.

Supplier: Different suppliers may have varying pricing strategies and overhead costs, resulting in price disparities.

If you’re looking to minimize costs while still obtaining high-quality stainless steel banding, consider the following tips:

Compare Prices: Shop around and compare prices from multiple suppliers to ensure you’re getting the best deal.

Bulk Purchasing: Buying stainless steel banding in bulk can sometimes lead to cost savings.

Consider Alternatives: Depending on your specific application, it may be worth exploring alternative materials or banding methods that offer similar benefits at a lower cost.

The cost of stainless steel banding can vary greatly depending on the source and various factors such as material, width, and thickness. It’s essential to conduct thorough research, compare prices, and consider other factors like shipping costs and availability before making a purchasing decision. By doing so, you can ensure that you find the best price while still obtaining high-quality stainless steel banding.

Remember, the information provided in this article is subject to change, and it’s always recommended to stay informed and choose wisely when it comes to your stainless steel banding needs.

“Investing in high-quality stainless steel banding is crucial for industries that prioritize strength and durability. By understanding the factors influencing pricing and comparing options, businesses can make cost-effective decisions while still maintaining the integrity of their projects.”**