Chromium (Cr) is a significant portion of the total content in steel alloys that contain 11% or more chromium by mass.When soft annealed, the ferritic crystal structure of A240 Material grade stainless steel (also known as stainless steel A240) is ferromagnetic. The high chromium content of this steel allows it to be used in some applications where conventional austenitic grades are not suitable. As a result, ASTM A240 grade 301 304L 316 316L 321 stainless steel plate is widely used in a variety of applications, including raw materials for pipelines and tubes, pressure vessels, food and beverage processing, water treatment, storage tanks, acid manufacturing equipment, utensils, machines, metal wires, and petrochemical components.

ASTM A240 is a specification for stainless steel plates, sheets, and strips intended for use in pressure vessels and other general applications. This specification covers a variety of different stainless steel alloys, including ferritic, austenitic, martensitic, duplex, super duplex, and high molybdenum.

For a more detailed explanation of how to manufacture in accordance with the ASTM A240 specification, see here. We’ve compiled a list of the most frequently used materials, such as those listed above, that can be used to manufacture in accordance with the ASTM A240 specification, including 304, 304L, 316, 316L, 321, 347, 309, 310, 316Ti, 317L, Xm-19, 904L, 409, 410, 430, Duplex S31803, S32205, Super Duplex S32750, S32760, S

The following specifications are necessary: This specification covers chromium, chromium-nickel, and chromium-manganese-nickel stainless steel plate, sheet, and strip used in a variety of applications, including building construction.

ASTM A240 steel plates are available in Austenitic, Ferritic, and Martensitic grades. In different industries, different types of stainless steel are used such as 304/340L, 316/316L. It is an excellent material steel plate due to the fact that it offers a wide range of dimensional features, a multitude of surface finishes, and premium quality assurance and delivery times.

According to ASTM A240, these materials are classified as chromium nickel chromium alloys, the same as chromium nickel chromium alloys (316 and 316L). Molybdenum is frequently added to stainless steel to increase its corrosion resistance, which makes the 316/316L variety more corrosion resistant than the 304/304L variety. Because the carbon content of 316L steel is only slightly greater than that of 316 steel, the slightly stronger variant of 316L steel is designated as “316L steel.” While 316L is nearly identical to 316, the other grades are noticeably different. Because 316L contains less carbon than the starting material, it can be used as a pretreatment.

Additionally, 316/316L steel is extremely resistant to corrosion, regardless of whether it is welded or immersed in seawater. Though 316/316L steel does not contain detectable amounts of magnetic material when cold drawn or cold rolled, the manufacturing process may occasionally result in the presence of trace amounts of magnetic. If the steel is correct, the problem may be resolved through additional processing.

While non-carbonized stain-proof steels are significantly less prone to corrosion, staining, and rusting, they lack stain-proof properties.

When selecting a corrosion-resistant steel for aircraft, opt for an alloy containing no more than 12% chromium. Stainless steel is available in a variety of grades and surface finishes for home appliances, clothing, and utensils, ranging from high-end to low-end kitchen utensils.

It is very important to remember that different types of stainless steel have different levels of resistance to oxidation (rust) and corrosion, which is why it is critical to select stainless steel carefully for a particular environment. Another interesting point to consider is that, of the fifteen stainless steel grades, three of them are commonly known as “stainless.”

ASTM A240 Materialgrades 304 and 304L are two different ASTM A240 material steel grades.

Stainless steel 18-8 is a type of stainless steel that is frequently referred to as 18-8 stainless steel. It contains 18% chromium and 8% nickel. 304 stainless steel is one of the most versatile stainless steel options available today. It is extremely adept at putting things together and creating things out of thin air.

As far as the fabrication of stainless steel products is concerned, 304 and 304L grades of stainless steel plate are the most popular, respectively. In the past, 304 stainless steel has been used in the manufacture of many different products, including containers, vessels, air conditioners, and transformers for various industries, as well as in building and transportation applications. As far as the cost is concerned, the most cost-effective option is 304L.

Try for free information about the A Complete Guide to Stainless Steel AISI 420

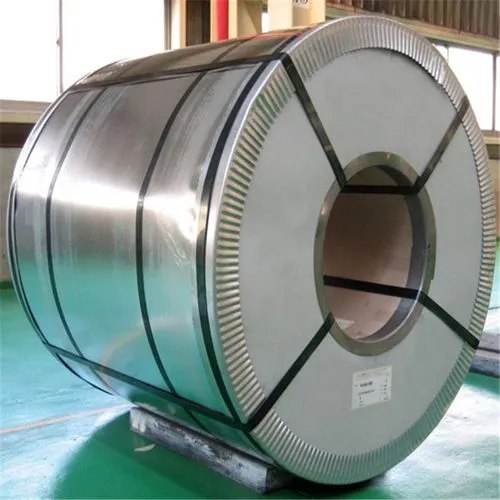

You can get the more cost-effective 301 stainless steel material from Yaoyi. Thickness 0.1 mm~0.3 mm, width 550-600 mm cold rolled stainless steel coil.

It is widely used in a variety of household and industrial applications, including food handling and processing, storage tanks, and medical equipment.

ASTM A240 316 (S31600) is a grade of stainless steel that incorporates additional molybdenum and nickel compared to 304.

The sheets in sheet set 201 adhere to ASTM A240 specifications, which call for a minimum Tensile Strength of 515 MPa, a minimum Yield Strength of 260 MPa, and a minimum elongation of 201.

When designing stainless steel 201, I’ve taken good machinability, corrosion resistance, and formability into consideration. This all points to a fantastic choice for the substrate material.

Read more about A Complete Guide to SUS Stainless Steel Banding

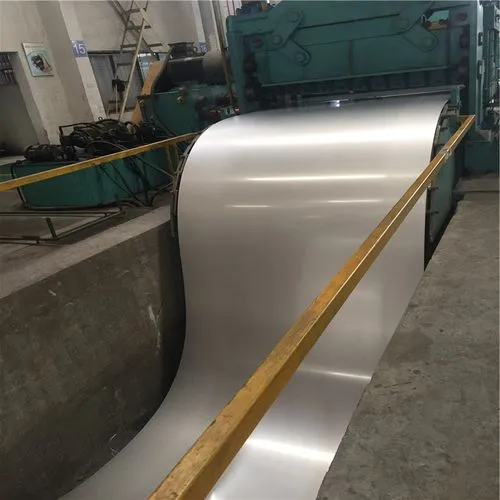

The slab must be conditioned prior to stretching. Therefore, in order to stretch the slab, slabs or sheet bars are hot rolled and then finished on a finishing mill. When making steel, continuously casting already hot-rolled slabs into steel continuously cools the new steel. It is then further processed on a finishing mill.

In contrast, sheets are wound directly off the mills, as if they were made into a coil, rather than continuously rolled through the mills. Once the minerals in the water have been removed, these bands are allowed to expand to their full length, after which they are drawn down to their required thickness. While annealing and descaling the cold mill coils is dependent on whether or not the cold mill coils are then bright annealed or cold drawn, the coils are either bright annealed or cold drawn.

When the belt is hot, it may be necessary to grind off surface defects using a belt grinder. The coils and lengths will be replaced if they have been cut all the way through, and only the full length of the coil or coil section is left.

In some cases, sheets may be shipped in coils, or they may be rolled flat.

The manufacturing and heating treatment process for A240 materials is A240 is the manufacturing and heating treatment process

In order to produce flat-rolled stainless steel products, an electric-arc or electric-induction melting or remelting process must be used to create the base material. Generally, plates are made by one of three processes: hot rolling, slab casting, or rolling.

Once the plate is made more durable, it may be conditioned to increase its lifespan. This approach is only employed when necessary: some molds are made from rolling molten metal into ingots, while others are formed directly from molten metal. ASTM A240 Material specifies that the steel should be made and annealed raw, and this can be done using a blast cleaning or pickling process. Mill edge and uncropped edges are among other manufacturing processes that can be used. Plates can only be trimmed along the long and short sides when rolled along the horizontal and vertical axes.

The sheet is sometimes rolled between horizontal and vertical rolls and only trimmed on the ends. It is known as sheared plate or sheared mill plate when rolled between horizontal rolls, but when rolled between horizontal and vertical rolls, and trimmed elsewhere, it is referred to as universal plate or universal mill plate.

Additionally, stainless steel strips, which are hot-rolled, annealed, and pickled, are made from cold-rolled, annealed, and pickled slit sheets (or from hot-rolled, unannealed, and unpickled strips). The final product should be formed in such a way as to ensure surface characteristics and mechanical properties are retained. If not, this could lead to reduced strength and durability.

This is because it is produced from hot-rolled slabs or billets, which makes it a partially completed product that is produced by cold-rolling to turn the strip into finished product. To varying degrees, it is possible to find different types of stainless steel 304/304L and 316/316L strip thicknesses for different uses on all varieties of stainless steel 304/304L and 316/316L, including for annealing, for annealing and skin-passing, or for bright annealing.

While edge conditioning is more important on strips, it is not important on sheets at all. Specifying the length and width of an edge so that the configuration options vary according to those specifications, such as providing a selection of centimeters, centimeters, and millimeters, is a way to customize strip length and width. Rolled edges are only used if they are specified. This particular type of edge is created by cutting through the board lengthwise. Nope. That would be No. 5, which features a nearly square edge, as produced by rolling or filing after the slitting of a piece.

Stainless steel grades in the 450 series are most frequently used in tubular products such as those used in the automotive industry and process equipment.

Tanks, supports, frames, enclosures, and housings, as well as engines, motors, and machinery components and parts, are all included in this system.

As previously stated, the 316L plate is used in the manufacture of a variety of products that are exposed to seawater, acids such as sulfuric acid and chloride, petrochemicals, and various chemicals, as well as those that are exposed to high heat, such as engines and motors.

304L stainless steel sheets and plates are commonly used in the fabrication of chemical vessels, seawater, and salt water installations. 304L stainless steel is used in nuclear power plants due to its high cost and structural integrity.

This is an excellent choice if you require a stronger and more corrosion-resistant alternative in the presence of sulfuric acid. Grade A240 Material stainless steel is used in a variety of applications, including furniture and architectural design. Elevators and door frames constructed of grade A240 stainless steel are used in elevators and architectural design. Numerous structures should have their construction, household, and catering areas expanded.

Please contact us if you need the high-quality moral materials.

Keep reading:A complete guide to SUS 304 stainless steel

The ASTM A240 Material specification outlines the physical and mechanical properties required for stainless steel plates, sheets, and strips used in pressure vessels and for general applications. Properties encompassed in this standard include yield strength, tensile strength, elongation, hardness (Brinell and Rockwell), and thickness. Materials under this specification are expected to conform to specified chemical compositions of several elements such as carbon, manganese, phosphorous, sulfur, silicon, chromium, nickel, molybdenum, and nitrogen.

The “M” in ASTM A240/240M denotes that this standard is the metric version. While the standards are technically equivalent, ASTM A240M is expressed in metric units, and ASTM A240 is in Imperial units.

The equivalent standard to ASTM A240 would depend on the specific jurisdiction or standardization body. For instance, the EN 10088-2 is similar to the ASTM A240 in the context of European standards.

ASTM A240 304 stainless steel has a very good resistance to corrosion in various environments. It can resist most oxidizing acids and can withstand ordinary rusting in architecture. Additionally, it is resistant to food processing environments, can withstand both organic and inorganic chemicals, and hot petroleum products.

The ASTM A240 material specification provides guidelines for the production and supply of chromium, chromium-nickel, and chromium-manganese-nickel stainless steel plate, sheet, and strip. These materials are intended for pressure vessels and for general applications. The specification includes requirements for heat treatment, mechanical properties, and finishes.

SA 240 Duplex 2205 is a grade of duplex (austenitic-ferritic) stainless steel that provides a beneficial combination of high strength, high corrosion resistance, and excellent stress corrosion cracking resistance. It contains about 22% Chromium, 5% Nickel, and 3% Molybdenum with the balance being Iron. Its high corrosion resistance makes it suitable for environments containing chlorides and other