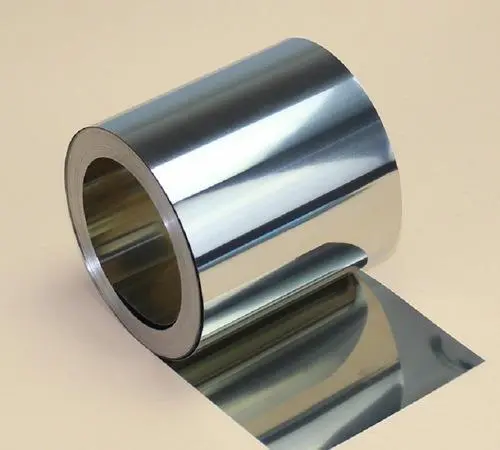

Dive into the captivating world of Stainless Steel (SS) Foil with us. This guide demystifies its manifold uses, unravels the differences between SS Foil and its counterparts, and illustrates the meticulous manufacturing process behind it. We will also delve into the roles of alloying elements and how to select the right SS Foil grade for your application. With decades of craftsmanship, Yaoyi Stainless Steel guarantees not just product, but a partnership in your success story. Let’s journey together to explore the unparalleled utility and versatility of SS Foil.

Dive into the world of Yaoyi Stainless Steel now and find the perfect SS Foil for your needs. Act today, excel tomorrow!”

Stainless steel foil, or SS foil, has vast applications due to its key features such as corrosion resistance, high temperature resilience, and mechanical strength.

In the aerospace industry, SS foil is used for its high-strength and high-temperature resistance. It is commonly used in shims, washers, and spacers in aviation components.

In the medical field, SS foil is used for its corrosion-resistant quality. It is commonly used in surgical instruments, dental appliances, and more.

In the electronics industry, it is frequently used in parts that require excellent conductivity. This metal foil is used in connectors, lead frames, and more.

In the automotive industry, SS foil plays a crucial role. Its corrosion resistance and durability make it ideal for components in both interiors and exteriors of vehicles.

SS foil is also a significant player in the food and beverage industry. It is typically used in food processing equipment, brewery equipment, kitchen appliances, and more due to its anti-corrosive nature and food-grade quality.

The SS Foil produced by Yaoyi Stainless Steel caters to these industries and more, ensuring quality, durability, and tailored solutions for every requirement.

SS Foil boasts several advantages over materials such as titanium foil or carbon steel foil. Its primary benefits include corrosion resistance, high temperature tolerance, and excellent mechanical properties.

One of the key features that set SS Foil apart from other materials is its superior corrosion resistance. Unlike mild steel foil or iron foil, SS Foil has a chromium-rich surface that prevents rust and corrosion, making it ideal for various applications.

Another significant advantage of SS Foil over titanium foil is its high-temperature tolerance. It maintains its properties even in extreme heat, making it suitable for aerospace and industrial applications.

In terms of mechanical properties, SS Foil outshines carbon steel foil. It has excellent formability, strength, and hardness that makes it preferred in manufacturing, automotive, and medical industries.

Overall, SS Foil offers a superior combination of properties than other materials like titanium foil and carbon steel foil. It provides a perfect blend of performance and durability to meet diverse industrial requirements.

Yaoyi Stainless Steel is known for manufacturing high-quality stainless steel foils. These foils are meticulously made with attention to every detail, ensuring they meet the highest standards of quality.

Yaoyi Stainless Steel produces foils in grades including but not limited to 301, 304, 316, and 316L. These are all austenitic grades known for their corrosion resistance and formability.

The thickness of the stainless steel foil ranges from 0.01mm to 0.05mm. This range offers flexibility for various applications, from aerospace to electronics.

Each batch of stainless steel coils is tested for hardness, elongation, and chemical composition, with a CNC system controlling the thickness tolerance within 0.005mm. This precision ensures consistency in quality and performance of the stainless steel foils produced.

Through its commitment to quality and precision, Yaoyi Stainless Steel provides industry-leading stainless steel foils that meet diverse client requirements.

Hardness is a critical property of stainless steel foil. It plays a vital role in determining where the foil can be used, and how it will perform in those applications.

Harder stainless steel foils, such as those produced by Yaoyi, have a higher resistance to wear and tear. This makes them ideal for use in environments where the foil is subjected to physical stress and strain.

The hardness of SS foil also affects its deformability. Harder foils are less prone to deformation, which makes them suitable for applications that require maintaining a certain shape or form under stress.

In industrial applications, the hardness of stainless steel foil can determine its suitability for certain tasks. For example, harder foils are often used in the manufacturing of parts and components that require high strength and wear resistance.

Overall, the hardness of stainless steel foil is a key factor to consider in its application. With its extensive expertise, Yaoyi Stainless Steel can guide customers in selecting the right foil for their specific needs.

The magnetism of stainless steel foil is primarily dependent on the type and grade of stainless steel used.

The stainless steel foils produced by Yaoyi, such as grades 301, 304, 316, and 316L, belong to the austenitic family of stainless steel, which is generally non-magnetic.

However, these materials can become slightly magnetic after cold working processes due to the formation of a different crystal structure, known as martensite. This phenomenon is known as work hardening.

The largely non-magnetic nature of austenitic stainless steel foils, such as those produced by Yaoyi, makes them ideal for use in applications where magnetism could be problematic, such as in electronic components.

Whether a magnetic or non-magnetic material is required, Yaoyi Stainless Steel is equipped to provide the right stainless steel foil to meet your needs.

SS foil and stainless steel sheets are both forms of stainless steel, but they have significant differences in their thickness and uses.

The primary difference between the two is their thickness. SS foil is thinner, typically ranging from 0.01mm to 0.05mm, while stainless steel sheets are generally thicker.

Due to its thinness, SS foil is more flexible and formable than stainless steel sheets. This makes it suitable for applications that require wrapping, shaping, or molding the material around objects.

While stainless steel sheets are used in large-scale applications like construction and heavy machinery, SS foil’s applications are more nuanced, including electronic parts, automotive components, and medical equipment.

Understanding the differences between SS foil and stainless steel sheets can help in selecting the right material for your needs, and Yaoyi Stainless Steel is ready to guide you through this process.

Stainless steel (SS) foil and carbon steel foil, though both are used in various applications, differ fundamentally in their composition, properties, and uses.

Stainless steel foil, like those made by Yaoyi, is primarily composed of iron, carbon, and chromium, while carbon steel foil contains mainly iron and carbon.

One of the most notable differences is their resistance to corrosion. SS foil, due to its chromium content, exhibits excellent corrosion resistance, unlike carbon steel foil which is prone to rusting.

The corrosion resistance of SS foil makes it a preferred choice in applications where the material is exposed to moisture or corrosive environments, such as in food processing, medical devices, and electronics.

Determining whether to use SS foil or carbon steel foil will depend on your specific requirements. With their vast experience, Yaoyi’s team can help guide you to the right choice for your needs.

The manufacturing of SS foil is a complex process that involves multiple stages to ensure the end product’s high quality and precise thickness.

The process begins with the melting of raw materials, including iron, chromium, and nickel, in an electric furnace. This molten metal is then cast into a slab or billet.

The slab is then hot rolled, a process that involves heating the slab and passing it through large rolls to reduce its thickness.

Cold rolling is the crucial process in the manufacture of SS foil. Here, the strip is further reduced to its final thickness using a rolling mill. Yaoyi’s state-of-the-art CNC system controls the thickness tolerance within 0.005mm.

Finally, the SS foil undergoes annealing and finishing processes to enhance its mechanical properties and surface finish.

This is a simplified overview of the complex process that Yaoyi Stainless Steel uses to produce its high-quality, ultra-thin stainless steel foils.

Alloying elements in stainless steel foil contribute significantly to its properties and performance.

Chromium is a crucial element in stainless steel, including SS foil. It provides corrosion resistance by forming a protective, adherent oxide layer when exposed to air.

Nickel improves the formability and ductility of the stainless steel foil. It also enhances corrosion resistance in certain acidic environments.

Carbon increases the strength of the stainless steel. However, it may decrease the material’s resistance to corrosion at high concentrations, so its levels are carefully controlled in stainless steel foil.

Other elements, such as manganese and nitrogen, can also play a role in enhancing the strength, workability, and corrosion resistance of SS foil.

The exact composition of a particular stainless steel foil will depend on its specific grade and intended application. Yaoyi Stainless Steel ensures each SS foil it produces meets the desired properties by precisely controlling the alloying elements.

Choosing the right grade of SS Foil is crucial for the performance and longevity of your end product. Several factors need to be considered.

First, understanding the environment and application where the foil will be used is critical. Is it exposed to corrosive elements? Is it expected to bear heavy loads? Each application has different requirements for strength, corrosion resistance, formability, and thermal resistance.

Next, consider the properties of different grades of SS Foil. For instance, 304 and 316L grades offer excellent corrosion resistance, while 301 is known for its high strength and hardness.

Ensure that the selected grade complies with the relevant standards and regulations of your industry.

Lastly, consulting with stainless steel experts, like the engineers at Yaoyi, can provide valuable guidance. They can help align the material’s properties with your requirements, ensuring the optimal performance of your SS Foil.

Choosing the right SS Foil grade can seem daunting, but with a comprehensive understanding of your needs and the properties of different grades, it becomes a manageable task. Remember, Yaoyi Stainless Steel is always there to guide you in making the best choice.

Learn more about the : 0.01~0.05mm Stainless Foil: A Comprehensive Guide

Stainless steel foil is a crucial material in various industries, offering durability, corrosion resistance, and versatility. If you’re wondering about the cost of stainless steel foil, you’ve come to the right place. In this article, we will delve into the different factors that influence the price of stainless steel foil and provide you with valuable insights.

Several key factors contribute to the price range of stainless steel foil. Understanding these factors will help you make informed decisions when purchasing stainless steel foil for your specific needs. Let’s explore them:

The type and grade of stainless steel foil play a significant role in determining its price. Different types and grades offer varying levels of corrosion resistance, strength, and other properties. Here are a few common types:

Type 304: This widely used grade is known for its excellent corrosion resistance and versatility. It finds applications in food and beverage, machinery, aerospace, and architecture. The price range for Type 304 stainless steel foil is typically between $405.96 and $557.70, depending on the thickness and length of the roll.

Type 316: Renowned for its superior corrosion resistance, Type 316 stainless steel foil is often used in marine and chemical applications. A 0.002″ thick, 1200″ long roll of Type 316 stainless steel foil can cost around $993.37.

Other Types: There are numerous other types of stainless steel foil available, each tailored to specific applications. For instance, certain foils are designed for the electronics sector due to their electromagnetic interference shielding capabilities. The prices of these other types of stainless steel foil vary based on the specific grade and supplier.

The choice of supplier and the quantity of stainless steel foil you require can also impact the overall cost. Different suppliers may offer varying prices based on factors such as production costs, market demand, and their own pricing strategies. Additionally, purchasing larger quantities of stainless steel foil may lead to volume discounts, reducing the overall price per unit.

Like any commodity, the price of stainless steel foil is influenced by market conditions. Factors such as supply and demand dynamics, global economic trends, and geopolitical events can cause fluctuations in prices. It’s essential to stay updated on market trends to make well-informed decisions regarding your stainless steel foil purchases.

To help you visualize the different types of stainless steel foil and their respective price ranges, we have prepared a flowchart, chart, and table:

| Type | Price Range |

|---|---|

| Type 304 | $405.96 – $557.70 |

| Type 316 | $993.37 |

| Other Types | Varies |

In conclusion, the cost of stainless steel foil depends on various factors, including the type and grade of the foil, the supplier, quantity, and market conditions. It is crucial to consider these factors when estimating the price of stainless steel foil for your specific requirements. By understanding these factors and conducting thorough research, you can make informed decisions and find the best value for your investment.

Note: The prices mentioned in this article are for illustrative purposes only and may not reflect the current market prices. It is advisable to consult with suppliers and conduct market research to obtain accurate and up-to-date pricing information.

Remember, stainless steel foil is an investment in quality and durability, and finding the right balance between cost and performance is key.

Learn more about the : 0.01~0.05mm Stainless Steel Foil Exhaustive Guide

Learn more about the : AISI 301 Equivalent: Components, Processing, And Applications