Stainless steel coils are essential components across multiple industries, from construction to consumer goods and renewable energy. Understanding the stainless steel coil manufacturing process is critical for engineers, manufacturers, and buyers who seek high-quality products. This article provides a detailed, human-written, and SEO-optimized guide on how stainless steel coils are produced, their types, applications, and key considerations for quality and performance.

Introduction to Stainless Steel Coils

Stainless steel is an alloy primarily composed of iron, chromium, and other elements that enhance its corrosion resistance. According to Wikipedia, stainless steel is highly durable, making it ideal for applications where hygiene, corrosion resistance, and aesthetics matter.

Coils are long strips of stainless steel wound into rolls for easier handling, transportation, and processing. The stainless steel coil manufacturing process involves precise techniques to ensure strength, surface finish, and resistance to wear. Industries like medical devices, automotive, and construction rely heavily on these coils for their production lines.

For more details on the various types of stainless steel coils and their uses, visit Stainless Steel Coil Consumer Goods Types & Uses.

Understanding the Stainless Steel Coil Manufacturing Process

Raw Material Selection

The first step in the stainless steel coil manufacturing process is selecting high-quality raw materials. Stainless steel is primarily made from iron, chromium, nickel, and molybdenum. The proportions of these elements determine the alloy grade. For instance, 304 stainless steel is popular for its general corrosion resistance, whereas 316 stainless steel contains molybdenum for enhanced resistance to chlorides and acids.

Suppliers often source raw materials from certified mills to ensure consistency in chemical composition. Impurities can lead to defects like pitting, reduced ductility, or uneven finishes.

Melting and Casting

The selected raw materials are melted in an electric arc furnace (EAF) or induction furnace. The molten metal undergoes careful chemical analysis to ensure proper composition. Once balanced, the molten steel is cast into slabs, blooms, or billets.

Casting can be continuous or ingot-based. Continuous casting is more efficient, producing uniform slabs that reduce waste. This step is critical for achieving uniform thickness and surface quality in the final coil.

Hot Rolling

The next phase is hot rolling, where the steel slabs are heated to 1100°C to 1250°C and passed through rollers to reduce thickness. Hot rolling improves ductility, eliminates internal voids, and prepares the steel for further processing.

During hot rolling, annealing is often performed to relieve internal stresses. The hot-rolled coil may undergo descaling, where scale formed during heating is removed, leaving a smooth surface.

Learn more about the production process here: Stainless Steel Coil Production Process Guide.

Pickling and Cleaning

Hot rolling often leaves oxide layers on the steel surface. Pickling, an acid-based cleaning process, removes these oxides, improving corrosion resistance and preparing the steel for finishing. Typically, nitric acid or a mixture of nitric and hydrofluoric acids is used.

After pickling, the steel is thoroughly washed to remove acid residues and dried to prevent oxidation.

Cold Rolling

Cold rolling is performed at room temperature to achieve precise thickness and superior surface finish. This step also enhances mechanical properties such as tensile strength and hardness. Stainless steel coil thickness can be reduced to fractions of a millimeter depending on application requirements.

Cold rolling involves multiple passes through rolling mills, with intermediate annealing cycles to maintain ductility. This results in high-quality stainless steel coils with excellent surface uniformity, ideal for consumer goods and industrial applications.

For high-grade options, see 316 Stainless Steel Coil.

Annealing and Surface Finishing

After cold rolling, the coil undergoes annealing in a controlled atmosphere furnace. This step restores ductility and removes stresses introduced during rolling. Annealed coils are then pickled again to remove any oxide layers formed during heat treatment.

Surface finishing can include grinding, polishing, or brushing to achieve specific finishes such as 2B, BA (bright annealed), or No. 4. The finish selection depends on aesthetic requirements, corrosion resistance needs, and end-use applications.

Learn about heat treatments for specialized applications: 316 Stainless Steel Strip Heat Treatment.

Slitting and Recoiling

After finishing, coils are slit into narrower widths or recoiled into custom sizes as per customer requirements. This flexibility ensures that the coils can be efficiently used in various applications like consumer goods and renewable infrastructure.

Quality Inspection

Every stainless steel coil undergoes stringent quality checks to ensure compliance with international standards. Inspections include:

- Thickness measurements

- Surface defect analysis

- Chemical composition verification

- Mechanical property testing

High-quality coils often receive certifications such as ASTM, EN, or ISO, guaranteeing consistent performance.

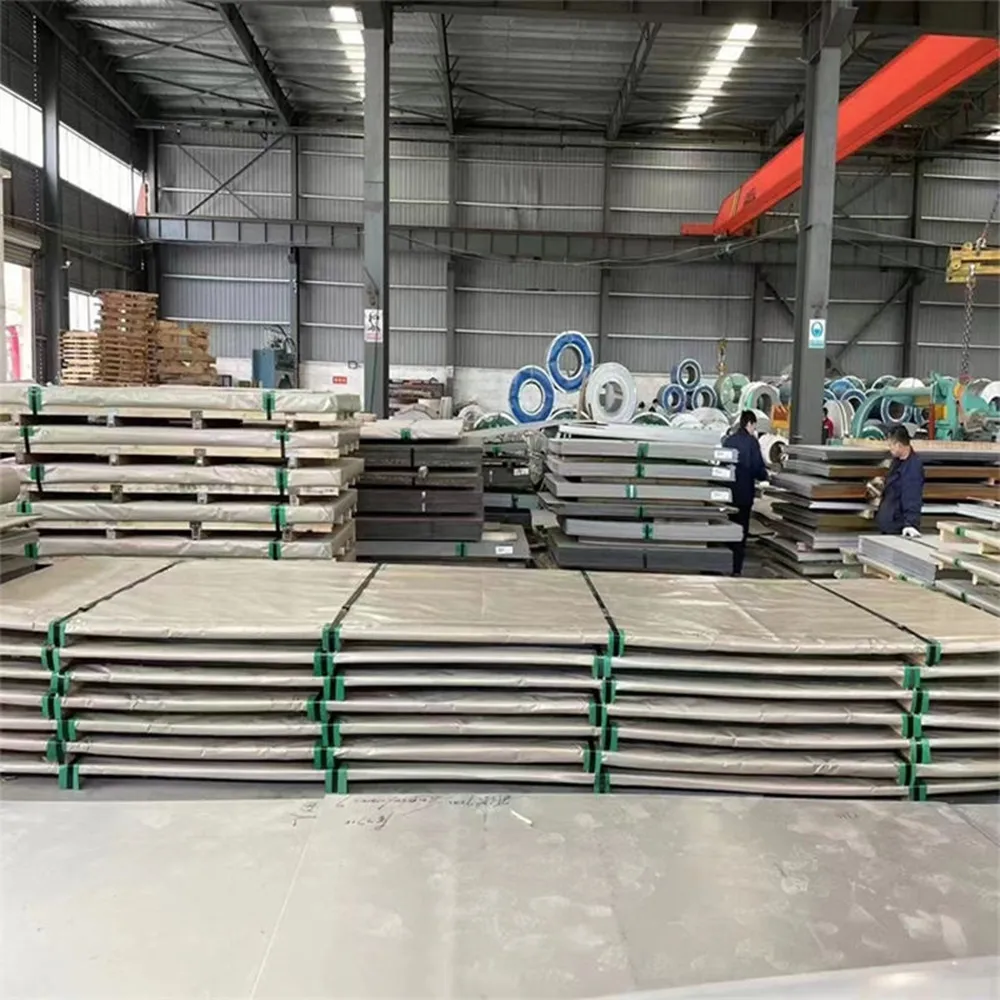

Packaging and Shipping

Finally, the coils are carefully packaged to prevent damage during storage and transportation. Protective wrapping, wooden pallets, and rust-inhibiting coatings are commonly used. Proper handling ensures that the stainless steel coil arrives at the customer site in optimal condition.

Types of Stainless Steel Coils

Stainless steel coils are classified based on chemical composition, finish, and application. The most common types include:

| Type | Composition | Common Uses |

|---|---|---|

| 304 | Chromium 18%, Nickel 8% | Kitchen equipment, consumer goods |

| 316 | Chromium 16-18%, Nickel 10-14%, Molybdenum 2-3% | Marine equipment, chemical processing |

| 430 | Chromium 16-18%, Ferritic | Automotive trims, appliances |

For an in-depth look at coil types and applications, see Stainless Steel Coil Consumer Goods Types & Uses.

Applications of Stainless Steel Coils

Consumer Goods

Stainless steel coils are widely used in producing household appliances, cutlery, and kitchen surfaces. Their corrosion resistance and aesthetic finish make them ideal for these applications.

Construction and Architecture

In modern architecture, stainless steel coils are used for facades, roofing, and structural components. The material’s strength and resistance to weathering are major advantages.

Renewable Energy Infrastructure

Stainless steel coils play a critical role in wind turbines, solar panel frames, and other renewable energy infrastructure due to their durability and corrosion resistance. Learn more at Stainless Steel Coil Renewable Infrastructure.

Medical and Pharmaceutical Equipment

High-grade stainless steel, especially 316 coils, is used in medical devices and surgical instruments. Its resistance to corrosion and sterilization processes ensures longevity and safety.

Automotive Industry

Automotive applications include exhaust systems, trims, and structural components. Stainless steel coils help improve vehicle longevity and reduce maintenance costs.

Key Considerations in Coil Manufacturing

- Grade Selection: Choose the appropriate grade (304, 316, or others) based on the environmental and mechanical requirements.

- Surface Finish: Consider the application when selecting finishes like 2B, No. 4, or BA.

- Dimensional Accuracy: Ensure thickness, width, and length meet precise specifications.

- Quality Certifications: Look for ASTM, ISO, or EN certifications for guaranteed performance.

For specialized needs, check our product page: 316 Stainless Steel Coil.

Advantages of Using Stainless Steel Coils

- Corrosion Resistance: Resistant to rust and chemical damage.

- Durability: High tensile strength and long service life.

- Aesthetic Appeal: Smooth finishes suitable for decorative applications.

- Recyclability: Environmentally friendly and sustainable.

- Versatility: Suitable for various industrial and consumer applications.

Summary

The stainless steel coil manufacturing process is intricate, involving raw material selection, melting, casting, hot and cold rolling, annealing, surface finishing, and quality inspection. High-quality coils are essential in consumer goods, construction, renewable energy, medical, and automotive applications. Understanding this process helps buyers, engineers, and manufacturers select the best coils for their specific needs. For more information on stainless steel coil products, visit Stainless Steel Foil.

FAQs

What is the primary process used in stainless steel coil manufacturing?

The primary process involves melting, casting, hot rolling, cold rolling, annealing, pickling, and finishing. Each step ensures the coil meets the required standards for durability and performance.

Which stainless steel grade is best for high corrosion resistance?

316 stainless steel offers superior corrosion resistance due to its molybdenum content, making it ideal for marine and chemical applications.

How is the surface finish determined for stainless steel coils?

Surface finish is determined by the rolling and polishing process. Finishes like 2B, No. 4, and BA are common, depending on the application and aesthetic requirements.

Can stainless steel coils be customized?

Yes, coils can be slit to specific widths, recoiled, and treated to meet custom thickness, finish, and mechanical property requirements.

What are common applications of stainless steel coils?

They are used in consumer goods, construction, renewable energy infrastructure, medical devices, and automotive components.

How do I ensure high-quality stainless steel coils?

Quality is ensured by selecting certified suppliers, performing chemical and mechanical tests, and choosing coils with relevant certifications such as ASTM or ISO.