304 Stainless Steel Foil Packaging for Transport Protection

When transporting 304 stainless steel foil, proper packaging is crucial to protect the delicate material from damage, moisture, and external

Stainless steel foil rolls are versatile materials used across various industries due to their durability, heat resistance, and adaptability. These foil rolls, often made from high-quality alloys like 304 stainless steel, serve numerous applications, from cooking to industrial processes. Their precise thickness, ranging from ultra-thin sheets to slightly thicker foils, makes them suitable for intricate tasks, offering both strength and flexibility. In this guide, we will dive into the essential aspects of stainless steel foil rolls, including their types, uses, and practical implementation.

Stainless steel foil rolls are thin sheets of stainless steel wound into rolls, designed for a variety of applications such as insulation, cooking, and industrial uses. The most common type, 304 stainless steel foil roll, is known for its excellent corrosion resistance and thermal properties, making it ideal for environments that require high durability. With precise stainless steel foil thickness options, these rolls offer an efficient solution for tasks where space constraints or delicate handling is essential.

Read more about the: 0.01~0.05mm Stainless Steel Foil Sheet Production: A Deep Dive

The 304 stainless steel foil roll is one of the most popular types due to its balance of strength and corrosion resistance. It is widely used in both household and industrial applications, such as in stainless steel foil for cooking and high-temperature environments. The 304 grade is resistant to oxidation and rust, ensuring longevity in various conditions.

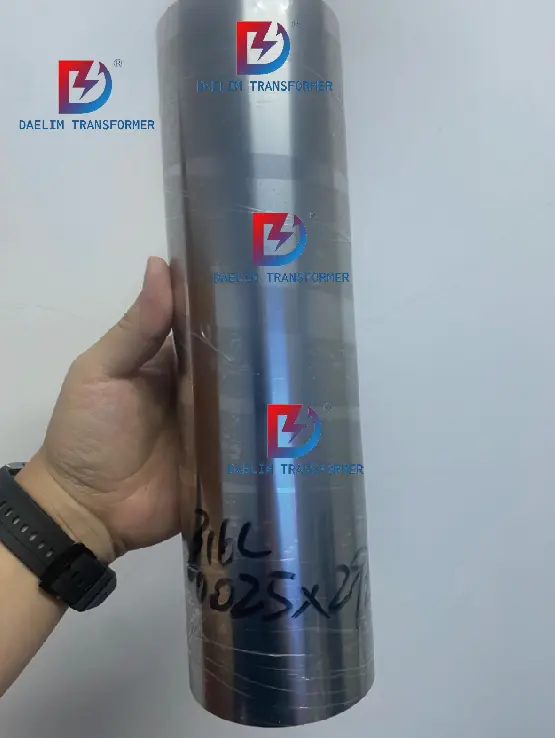

Stainless steel foil rolls come in different stainless steel foil thickness variants, allowing users to select the ideal thickness for their specific needs. Thin foils are often used in cooking applications or precision equipment, while slightly thicker options provide extra strength for demanding industrial tasks. Typical thicknesses range from 0.01 mm to 0.2 mm, giving users flexibility in their choice.

Stainless steel foil rolls feature a smooth, shiny surface that reflects their high quality and precision manufacturing. This characteristic makes them not only functional but also aesthetically pleasing, suitable for applications where the material is visible, such as architectural detailing. The polished finish helps resist contamination, making it a preferred choice in industries like food processing and pharmaceuticals.

Read more about the: Ss Foil 0.01~0.05mm: A Comprehensive Guide

When looking for stainless steel foil roll near me, it’s essential to seek reliable suppliers who can provide a range of options in terms of thickness and grade. Local suppliers often offer competitive stainless steel foil roll price and quick delivery times, making them an ideal choice for urgent needs. Many businesses also stock carbon steel foil as an alternative, though it lacks the corrosion resistance of stainless steel.

The stainless steel foil roll price depends on factors like thickness, grade, and supplier. Generally, 304 stainless steel foil roll tends to be priced higher due to its superior quality and versatility. Buyers should compare different suppliers to find the best balance between price and quality, especially for large-scale industrial purchases.

Manufacturing stainless steel foil rolls involves a precise process that transforms raw stainless steel into ultra-thin, highly durable sheets, which are then rolled for easy handling and transportation. This process requires advanced machinery and stringent quality controls to achieve the desired stainless steel foil thickness and surface finish. Below, we break down the key steps involved in making a stainless steel foil roll, emphasizing practical guidance and implementation.

The first step in creating stainless steel foil rolls is selecting the appropriate grade of stainless steel. 304 stainless steel foil is commonly used due to its excellent balance of corrosion resistance and formability. For specialized needs, other grades like 316 or even carbon steel foil can be used, depending on the required properties such as heat resistance or cost-effectiveness.

The selected stainless steel grade is melted in an electric arc furnace at high temperatures. This molten steel is then poured into a mold to form slabs. These slabs serve as the raw material for the subsequent rolling process, providing the necessary foundation to achieve the desired stainless steel foil thickness.

After casting, the slabs are heated to a high temperature and passed through hot rolling mills. The hot rolling process helps reduce the thickness of the steel slab significantly while improving its surface finish and grain structure. At this stage, the material is much thicker than the final foil but has a more manageable thickness, making it easier to work with.

The hot-rolled stainless steel undergoes cold rolling, a crucial step for achieving the precise stainless steel foil thickness required for foil rolls. During cold rolling, the steel passes through a series of rollers that gradually reduce its thickness to as little as 0.01 mm. This process ensures a smooth, uniform finish, making it suitable for high-precision applications like stainless steel foil for cooking.

After cold rolling, the stainless steel sheets are annealed—heated to a controlled temperature and then cooled slowly. This process softens the steel, relieving internal stresses caused by the rolling process and making it easier to form into a roll. Surface treatments like polishing or brushing may also be applied to enhance the foil’s reflective qualities and ensure a clean, smooth finish.

Once the desired thickness is achieved, the stainless steel sheets are cut into narrower strips through a slitting process. These strips are then wound into rolls to create the finished stainless steel foil roll. The width of the roll can vary depending on the intended use, whether for industrial machinery or smaller-scale stainless steel foil roll near me products.

The final stainless steel foil roll undergoes rigorous quality control checks to ensure uniform thickness, smooth surface, and adherence to specified mechanical properties. Once approved, the rolls are wrapped and packaged for shipment. Proper packaging is crucial to prevent damage during transportation and ensure the foil retains its high-quality finish until it reaches the customer.

Stainless steel foils generally range from 0.01 mm to 0.08 mm in thickness. This range of ultra-thin stainless steel sheets is produced through precision processes that ensure consistent thickness and high-quality surface finishes. Achieving such precise dimensions requires advanced rolling techniques, along with strict quality controls to maintain uniformity across the entire foil roll. Here’s a detailed explanation of how this thickness range is achieved:

The key process to achieve stainless steel foil thickness within the range of 0.01 mm to 0.08 mm is cold rolling. In this process, the stainless steel is first hot-rolled into thinner sheets, typically around 3 mm to 5 mm in thickness. Then, the cold rolling process reduces this thickness to the desired foil dimensions. Here’s how it works:

As the steel gets thinner, it becomes more rigid and prone to cracking during further rolling. Annealing is a critical step to address this challenge:

For foils thinner than 0.08 mm, precision grinding may be employed to ensure ultra-thin measurements like 0.01 mm. This step is especially critical for high-precision applications, such as those requiring stainless steel foil for cooking or medical uses:

After achieving the desired thinness, rigorous quality control measures ensure the stainless steel foil meets the specified range:

This combination of cold rolling, annealing, and precision grinding allows manufacturers to produce stainless steel foils with thicknesses as low as 0.01 mm and up to 0.08 mm, providing the versatility and quality needed for various industrial, commercial, and culinary applications.

Stainless steel foil rolls are highly versatile and can be used across a wide range of industries due to their durability, corrosion resistance, and heat tolerance. Their unique properties make them suitable for everything from industrial applications to everyday household uses. Here’s an overview of some of the most common uses:

Stainless steel foil rolls are frequently used in various industrial settings because of their strength and ability to withstand extreme temperatures and harsh conditions. Key applications include:

In high-tech industries like aerospace and automotive, stainless steel foil rolls are essential for components that require both strength and minimal weight:

The non-reactive and easy-to-clean nature of 304 stainless steel foil roll makes it suitable for use in sterile environments such as:

When transporting 304 stainless steel foil, proper packaging is crucial to protect the delicate material from damage, moisture, and external

The invention of stainless steel, often hailed as one of the most significant breakthroughs in metallurgy, was attributed to Harry