Welcome to the intricate universe of steel foil sheet. In this comprehensive guide, we delve into everything you need to know about Stainless Steel Foil Rolls — from their varied uses to the rigorous quality standards at Yaoyi, the leading manufacturer. Prepared with meticulous craftsmanship, our steel foil sheets embody a commitment to excellence and customer satisfaction. So, whether you’re interested in the technical specifications, potential applications, or the manufacturing process, read on to discover how Yaoyi’s superior quality steel foil sheets are driving success, one roll at a time.

Explore the world of steel foil sheets with Yaoyi, your trusted manufacturer. Discover top-quality Stainless Steel Foil Rolls for diverse uses. Act now, choose Yaoyi for success!

Steel foil sheets, especially Stainless Steel Foil Rolls, are highly versatile and are used in a variety of industries. From aviation and automotive to electronics and medical fields, these products are essential for countless applications.

In the aviation and automotive industry, they are used due to their strength and resistance to corrosion. From the intricate parts of an airplane engine to a car’s exhaust system, these foils play a crucial role.

In the electronics sector, steel foil sheets are used in microelectronics for packaging, and in heat sinks to help with heat dissipation.

In the medical field, their resistance to corrosion and sterilization ability make them ideal for surgical instruments and implants.

Steel foil sheets also have everyday applications, such as in cookware, kitchen appliances, and even steel foil for cooking.

Their aesthetic appeal and durability also make them popular in the construction industry, used in structures and fixtures.

Various manufacturing processes also use steel foil sheets due to their heat and chemical resistance.

In industrial machinery, they provide durability and corrosion resistance, extending the machine’s lifespan.

In the energy sector, they’re used in everything from nuclear reactors to solar panels due to their heat resistance and strength.

Lastly, in research and development fields, steel foil sheets are used for various experiments due to their unique properties.

The manufacturing process of steel foil sheets starts with the raw materials. The raw material, generally a form of steel alloy, is heated until it reaches a molten state.

This molten alloy is then cast into large blocks known as billets. These billets are the foundational building blocks of all steel products.

The billets are then put through a series of rolling operations. During this stage, the thickness of the steel is gradually reduced until it reaches the desired thickness of the steel foil sheet.

The process often involves cold rolling, where the steel is rolled at room temperature. Cold rolling increases the strength and hardness of the steel while reducing its ductility.

Quality control is critical at every stage of the process. For Yaoyi, each batch of stainless steel coils undergoes testing for hardness, elongation, and chemical composition, ensuring the best quality for our steel foil sheets.

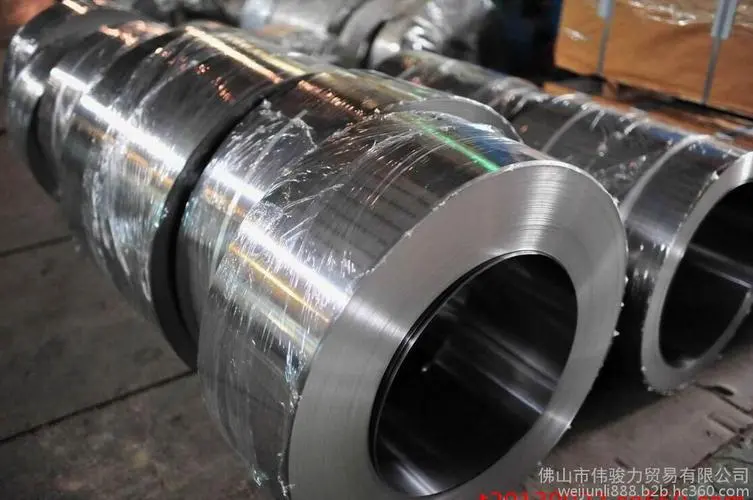

Once the steel has been rolled into sheets of the appropriate thickness, it is cut into the desired dimensions. The sheets are then coiled, ready for distribution.

Depending on the application, the steel foil sheets may undergo various surface treatments. These treatments can include cleaning, polishing, and coating to enhance the steel’s properties.

Some steel foil sheets undergo heat treatment. This process can increase the hardness, strength, and resistance of the steel. For instance, stainless steel foil for heat treating is specially designed to withstand high temperatures.

Finally, the steel foil sheets are carefully packaged to protect them from any potential damage during shipping.

The steel foil sheets are then ready to be shipped to customers, ready to be used in a multitude of applications.

Learn more about the: Ss Foil 0.01~0.05mm: A Comprehensive Guide

The production of steel foil sheets requires stringent quality control to ensure the best product for customers. For Yaoyi, quality control is not just an afterthought; it’s embedded in each stage of our manufacturing process.

Our quality control aligns with the ISO 9001 standards, with every batch of stainless steel coils undergoing thorough testing. We check the hardness, elongity, and chemical composition to ensure only the highest quality steel foil sheets leave our factory.

We employ advanced laboratory equipment in our quality control process. This technology enables us to analyze and perfect every facet of our product.

Our spectrometer, imported from Germany, is used to accurately analyze the chemical composition of the stainless steel strip. This level of precision guarantees that the final product meets our high standards.

Yaoyi also uses a CNC system to control the thickness tolerance of the stainless steel strip within 0.005mm. Such meticulous attention to detail ensures the consistency and reliability of our steel foil sheets.

Further, we provide rigorous testing services for our customers. Our experienced engineers are always ready to assist with problem-solving and product development.

Our commitment to quality doesn’t stop at our products. We’re continually improving our processes, incorporating feedback, and striving for excellence. Our customers’ success is our success.

Our dedicated team of professionals is the driving force behind our rigorous quality control. Their expertise and dedication ensure that every Stainless Steel Foil Roll meets our stringent standards.

At Yaoyi, quality isn’t just a word; it’s a standard we live by. And it’s this unwavering commitment to quality that makes us a leader in the production of steel foil sheets.

We stand by our products and our customers. We understand that when you succeed, we succeed. That’s why we’re dedicated to delivering high-quality, custom steel foil sheets that elevate your success.

The 301 steel foil sheet is a product of superior craftsmanship. It’s known for its excellent corrosion resistance, high strength, and impressive durability.

The high strength and durability of 301 steel foil make it a popular choice for applications requiring resistance to environmental conditions. These features make it perfect for industries such as automotive and aviation.

Despite its strength, 301 steel has exceptional formability. This makes it versatile and suited to a range of manufacturing processes.

The superior corrosion resistance of 301 steel foil sheets makes them perfect for applications that require longevity and resilience.

Like other Stainless Steel Foil Rolls, the 301 grade has commendable heat resistance, making it a viable option in high-temperature environments.

Beyond its functional properties, 301 steel foil sheets have a polished aesthetic, making them a stylish option for decorative and architectural applications.

Furthermore, 301 steel foil exhibits magnetic abilities, which can be beneficial in certain applications. This magnetic property can be enhanced or reduced depending on the specific needs of the application.

From automotive parts to kitchenware, electronics to aircraft components, the 301 steel foil sheet’s versatility and high performance meet the demands of a wide range of applications.

Just like with all our products, our 301 steel foil sheets undergo stringent quality control processes. We ensure that they meet our high standards and, more importantly, the standards and requirements of our clients.

By choosing our 301 steel foil sheets, you choose quality, performance, and reliability, propelling you towards your success.

Learn more about the: 0.01~0.05mm Stainless Foil: A Comprehensive Guide

Steel foil sheets, especially those made of stainless steel, are often employed in various cooking tasks. These foils provide a sanitary, heat-resistant, and non-reactive surface that’s ideal for a host of culinary applications.

Steel foil sheets are used in cooking to protect food from intense heat, preventing burning and sticking. They offer a practical solution for grilling delicate foods like fish.

When used to wrap foods, stainless steel foil helps to maintain moisture, enhancing the flavor and texture of the food. It’s particularly useful when baking or roasting.

Stainless steel foils can also help to distribute heat more evenly, leading to more consistent cooking results.

Steel foils, unlike some other materials, don’t react with acidic or alkaline foods. This makes them a safe choice for preserving food quality and taste.

Using steel foil sheets in cooking significantly reduces clean-up time. It protects your cookware from spills and hard-to-clean residue.

Steel foils are flexible, making them suitable for wrapping various shapes and sizes of food. From covering a turkey in the oven to wrapping a sandwich for a picnic, they’re incredibly versatile.

Our steel foil sheets are resistant to tearing, making them ideal for heavy-duty kitchen tasks.

As with all our products, Yaoyi ensures that our steel foils meet the highest quality standards, making them a reliable choice for your kitchen.

Our steel foils can enhance your culinary success, making them a valuable addition to any kitchen.

Certain grades of stainless steel, including the 301 and 304 grades, exhibit magnetic properties. These characteristics can be beneficial in various applications.

Cold working can enhance the magnetic properties of stainless steel foils. For instance, the 301-grade steel becomes increasingly magnetic with cold working.

The magnetic properties of certain stainless steel foils make them ideal for use in electronic devices that require interference shielding.

Magnetic stainless steel foils are also used in various parts of vehicles, particularly in components that require both strength and magnetic permeability.

At Yaoyi, we can tailor the magnetic properties of our stainless steel foils according to your specific needs, whether they need to be magnetic or non-magnetic.

Through rigorous quality control processes, we ensure the consistency and quality of our steel foil sheets, including their magnetic properties.

Our magnetic stainless steel foils can support your business in a range of applications, contributing to your overall success.

Our experienced engineers are always ready to help you find the best solutions to your challenges, including those related to the magnetic properties of stainless steel foils.

At Yaoyi, we promise to deliver only the highest quality products, meeting your needs and exceeding your expectations.

Whether you require magnetic or non-magnetic steel foil sheets, you can rest assured that quality is always our top priority.

Learn more about the: 0.01~0.05mm Stainless Steel Foil Exhaustive Guide

Carbon steel foil is a variation of steel foil where the main interstitial alloying constituent is carbon. It offers different properties than stainless steel, which can be advantageous in certain applications.

Carbon steel foils are known for their hardness, strength, and wear resistance. These qualities make them suitable for various industrial applications.

The robust properties of carbon steel foils make them suitable for tasks demanding high strength and durability. They are frequently employed in machine parts, tools, and automotive components.

To prevent rust, carbon steel foils often undergo various treatments or coatings. This enhances their longevity and ensures consistent performance.

Yaoyi offers customization options for carbon steel foils to suit specific applications, accommodating unique hardness, strength, and finish requirements.

Yaoyi delivers consistent, high-quality carbon steel foils, thanks to our rigorous quality control process in line with ISO 9001 standards.

Our team of experienced engineers is always available to help with any questions or challenges related to the use of carbon steel foil.

Our commitment to quality and customer satisfaction means we strive to exceed your expectations when delivering carbon steel foil.

With Yaoyi’s carbon steel foil, you’re set to forge the success of your applications. We ensure the strength, durability, and quality of each foil roll we provide.

Trust in the quality and reliability of Yaoyi’s carbon steel foils, and approach your project with confidence. Our foil will support your success.

Mild steel foil is a type of carbon steel foil known for its low carbon content. This makes it softer and more malleable than higher carbon alternatives.

Mild steel foil offers excellent weldability and machinability, making it an excellent choice for a wide range of applications.

Mild steel foil is versatile, serving uses in automotive parts, construction, and even some cooking utensils. Its ductility and weldability make it a favored choice.

Yaoyi can customize mild steel foil to meet the needs of various applications. We control the hardness, thickness, and other parameters to suit your requirements.

Yaoyi assures the quality of its mild steel foil, with rigorous checks at every stage of production.

Our expert team is always available to provide advice and support related to mild steel foils, ensuring you find the ideal solution for your needs.

Yaoyi promises to deliver mild steel foils that meet the highest standards of quality and performance.

We’re committed to contributing to your success by providing high-quality, reliable mild steel foils.

With Yaoyi, you can have confidence in every roll of mild steel foil you receive, knowing it will meet your requirements and perform to the highest standards.

When you choose mild steel foil, choose Yaoyi for its quality, expertise, and commitment to your success.

Learn more about the: AISI 301 Equivalent: Components, Processing, And Applications

Steel foil tape is a versatile product with a steel foil backing and a strong adhesive. It’s used for a variety of applications due to its conductivity, heat resistance, and durability.

Besides its strength and durability, steel foil tape also offers excellent heat and light reflection. It can withstand high temperatures, making it ideal for many uses.

Steel foil tape is commonly used in HVAC systems for duct sealing and repair. It’s also found in automotive applications and electromagnetic shielding.

Yaoyi produces top-quality steel foil tape, using the same rigorous quality controls and commitment to excellence we apply to all our products.

With our ISO 9001-compliant internal controls, Yaoyi guarantees the quality of each roll of steel foil tape we produce.

Our team of engineers is ready to assist with any queries or problems related to our steel foil tape, ensuring you can use our products confidently.

At Yaoyi, we’re committed to your success. That’s why we put so much effort into creating steel foil tape that meets the highest industry standards.

With Yaoyi’s steel foil tape, you can approach your projects with confidence, knowing you’re using a quality product that won’t let you down.

When you need steel foil tape, choose Yaoyi. Our commitment to quality and service means you won’t be disappointed.

With Yaoyi’s steel foil tape, your success starts here. We’re here to support your project every step of the way.

Heat treating involves heating or chilling materials to alter their physical and mechanical properties, without changing the product shape. It’s a common process in metallurgy.

Stainless steel foil plays a crucial role in the heat-treating process, often used as a wrap to prevent surface contamination.

Using stainless steel foil in heat treating protects components from the damaging effects of heat, like scaling and decarburization.

As always, Yaoyi assures the quality of the stainless steel foil used for heat treating. We adhere to the strictest internal control standards, in line with ISO 9001.

Our team of engineers can provide expert advice on using stainless steel foil for heat treating, helping you achieve the best possible results.

At Yaoyi, your success is our priority. That’s why we produce high-quality stainless steel foil for heat treating – to support your goals.

With Yaoyi, you can undertake your heat treating process with confidence, knowing that our stainless steel foil will deliver superior results.

When you choose Yaoyi’s stainless steel foil for your heat treating process, you’re choosing quality, reliability, and a commitment to your success.

With Yaoyi’s stainless steel foil for heat treating, a successful future starts here. Let us support your processes and help you achieve your goals.

Learn more about the: A Complete Guide To Stainless Steel Banding

Stainless steel foil tape is a unique product with excellent heat and light reflectivity. It is a robust and versatile product used in various applications due to its corrosion resistance, heat resistance, and durable nature.

The standout features of stainless steel foil tape include its ability to withstand high temperatures, making it suitable for demanding environments. It also offers a high degree of corrosion resistance, adding to its longevity.

Stainless steel foil tape finds usage in several industries. HVAC systems, automotive applications, and electromagnetic shielding are just a few areas where this tape shines.

Yaoyi’s stainless steel foil tape is crafted under strict quality controls and a dedication to perfection. We make sure every roll that leaves our factory meets or exceeds the industry standards.

Every batch of stainless steel foil tape from Yaoyi passes through our advanced laboratory. We test for hardness, elongation, and chemical composition to guarantee the quality of each batch.

Yaoyi’s team of skilled engineers is always ready to provide expert guidance regarding our stainless steel foil tape. We are here to assist you and solve any issues you might encounter.

At Yaoyi, your success is our success. That’s why we put so much effort into providing stainless steel foil tape that meets the highest industry standards.

Choosing Yaoyi’s stainless steel foil tape ensures that you’re investing in quality and reliability. We strive to provide the best so you can accomplish the most.

Choose Yaoyi’s stainless steel foil tape for your next project, and join the ranks of satisfied customers who’ve found success with our products.

Yaoyi’s stainless steel foil tape is the perfect start to your project’s success. We’re here to support you every step of the way.

Learn more about the: A Complete Guide To Stainless Steel AISI 420

When it comes to steel foil sheets, understanding the cost breakdown is essential for making informed purchasing decisions. The price of steel foil sheets can vary depending on several factors, including the type, dimensions, and supplier. In this article, we will explore the different aspects that influence the price of steel foil sheets, providing you with valuable insights into their cost.

Steel foil sheets come in various types, each offering unique properties and applications. Let’s take a closer look at some common types and their corresponding prices:

Type 304 Stainless Steel Foil Sheet

Type 304 Stainless Steel Foil Sheet

Type 304 Stainless Steel Foil Sheet

Type 316 Stainless Steel Foil Sheet

Other Types of Steel Foil Sheet

Please note that the prices mentioned above are indicative and may vary depending on the supplier, quantity ordered, and other factors. It is always recommended to contact suppliers directly for accurate and up-to-date pricing information.

Several factors contribute to the overall price of steel foil sheets. Understanding these factors will help you assess the cost breakdown more effectively. Let’s explore them:

| Type | Dimension | Price ($) |

|---|---|---|

| Type 304 | 0.05mm thick, 100mm wide, 2000mm long | 25.99 |

| Type 304 | 0.01mm thick, cold or hot rolled | 1050.00 – 1210.00 |

| Type 304 | 0.004″ thick | 15.00 per square foot |

| Type 316 | 0.003″ thick, 12″ x 1200″ roll | 60.00 |

| Other Types | Varies | Varies |

The type and grade of steel foil sheet play a significant role in determining its price. Different types of steel, such as Type 304 and Type 316, offer varying levels of corrosion resistance, strength, and durability. The price of steel foil sheets may vary based on the specific type and grade chosen.

The dimensions and thickness of steel foil sheets can impact their price. Sheets with larger dimensions or thicker gauges may require more raw material and additional processing, resulting in higher costs. It’s important to consider your specific requirements when selecting the dimensions and thickness of steel foil sheets.

The quantity of steel foil sheets ordered can affect the price per unit. Suppliers often offer volume discounts for larger orders, reducing the overall cost. If you have a significant requirement, it’s worth discussing potential discounts with your supplier.

The choice of supplier and prevailing market conditions can influence the price of steel foil sheets. Different suppliers may have varying pricing structures based on factors such as production costs, overheads, and market demand. Additionally, market conditions, including supply and demand dynamics, can cause fluctuations in prices.

To provide a visual representation of the cost breakdown of steel foil sheets, we have prepared a flow chart and a bar chart:

Conclusion

In conclusion, the cost of steel foil sheets is influenced by various factors, including the type, dimensions, quantity ordered, and supplier. By considering these factors and conducting thorough research, you can make informed decisions and find the best value for your investment. Remember to reach out to suppliers directly for accurate pricing information and stay updated on market trends.

Note: The prices provided in this article are for illustrative purposes only and may not reflect the current market prices. Prices can vary significantly based on several factors, and it is advisable to obtain up-to-date pricing information from suppliers.

Understanding the cost breakdown of steel foil sheets empowers you to make informed choices, ensuring that you select the most suitable option for your specific needs. Invest wisely in steel foil sheets, and unlock their potential for various applications across industries.