When it comes to modern industrial applications, stainless steel surface finishes play a pivotal role in determining both aesthetics and performance. Whether you are sourcing materials for home appliances, architectural projects, or industrial machinery, understanding the types, characteristics, and applications of stainless steel finishes ensures that your choice aligns with your project requirements. This guide covers everything you need to know, including common finishes, surface roughness, custom options, and usage scenarios.

Explore high-quality stainless steel products on Stainless Steel Foil.

What Is a Stainless Steel Surface Finish?

A stainless steel surface finish refers to the texture and appearance of the metal’s exterior after production. Stainless steel finishes are not only about aesthetics; they directly affect corrosion resistance, cleanliness, and durability. Different finishes are achieved through various processes such as rolling, polishing, or chemical treatment.

The finish impacts the performance in specific environments. For instance:

- Food and pharmaceutical industries often prefer smooth, polished surfaces for easy cleaning and hygiene.

- Architectural projects require visually appealing finishes that maintain luster over time.

- Industrial applications may prioritize rough finishes to increase friction or reduce glare.

Learn more about stainless steel’s general properties on Wikipedia.

What Are the Different Types of Stainless Steel Surface Finishes?

Stainless steel finishes are categorized based on processing methods, surface roughness, and visual appearance. Selecting the right finish requires understanding each type’s properties and applications.

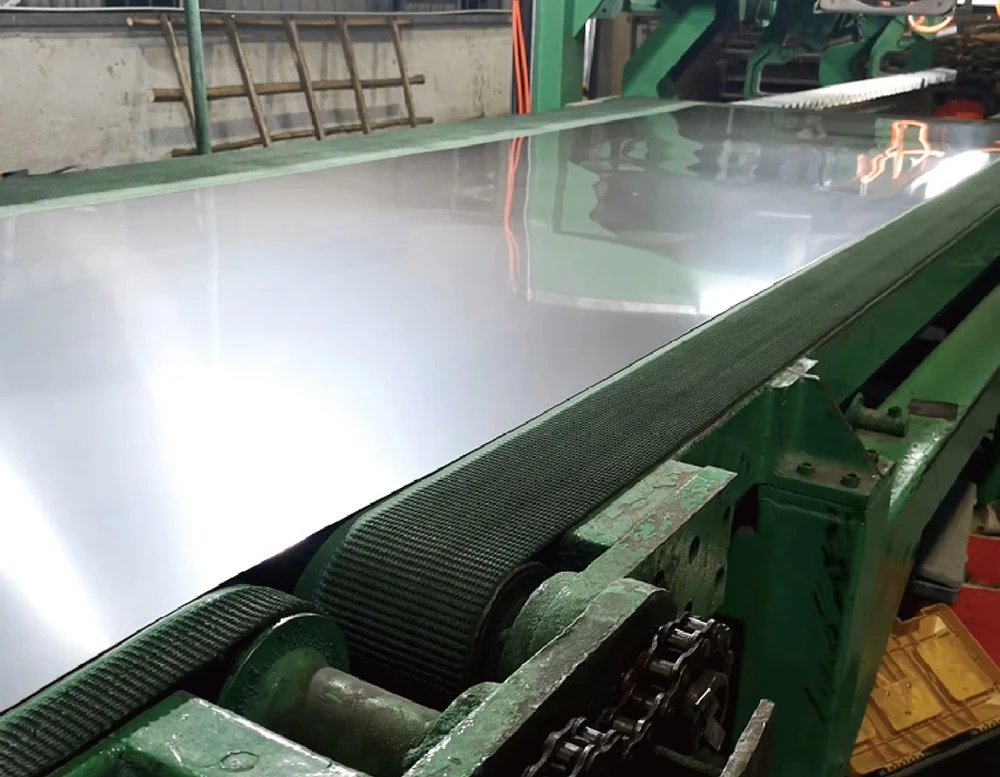

1. Mill Finishes

Mill finishes are the natural finishes applied during the manufacturing process. They result from hot or cold rolling and do not undergo further polishing or surface treatment.

Characteristics:

- Slightly rough texture

- Matte gray appearance

- Economical option

Applications:

- Industrial structures

- Temporary installations

For mill-finished stainless steel products, explore Stainless Steel Foil Products.

2. No. 1 Finish

The No. 1 finish is the result of hot rolling followed by annealing and descaling. It has a coarse texture, suitable for industrial applications.

Features:

- Dull, rough surface

- Resistant to corrosion after passivation

- Suitable for welding or fabrication

Applications:

- Chemical tanks

- Heat exchangers

3. No. 2D Finish

No. 2D finish is a cold-rolled, annealed, and pickled surface that’s smooth but not polished.

Characteristics:

- Smooth gray surface

- Economical and durable

- Moderate corrosion resistance

Applications:

- Automotive parts

- Sheet metal assemblies

More on 304 Stainless Steel Strip Surface Finish Options.

4. No. 2B Finish

The No. 2B finish is a cold-rolled, bright-annealed surface that is smoother than No. 2D. It is commonly used in precision applications.

Features:

- Smooth and reflective surface

- High corrosion resistance

- Ready for fabrication without additional finishing

Applications:

- Kitchen equipment

- Medical instruments

5. Bright Annealed (BA) Finish

Bright Annealed stainless steel is annealed in a controlled atmosphere to prevent oxidation, resulting in a reflective surface.

Features:

- Mirror-like appearance

- Superior corrosion resistance

- Excellent for architectural projects

Applications:

- Elevator panels

- Decorative cladding

Explore how stainless steel coils are used in consumer goods for practical insights.

6. Mechanically Polished Finishes

Mechanical polishing involves abrasives and polishing tools to achieve a smooth, visually appealing finish.

Types:

- Belt polishing

- Grinding

- Buffing

Benefits:

- Improved appearance

- Easier cleaning

- Enhanced corrosion resistance

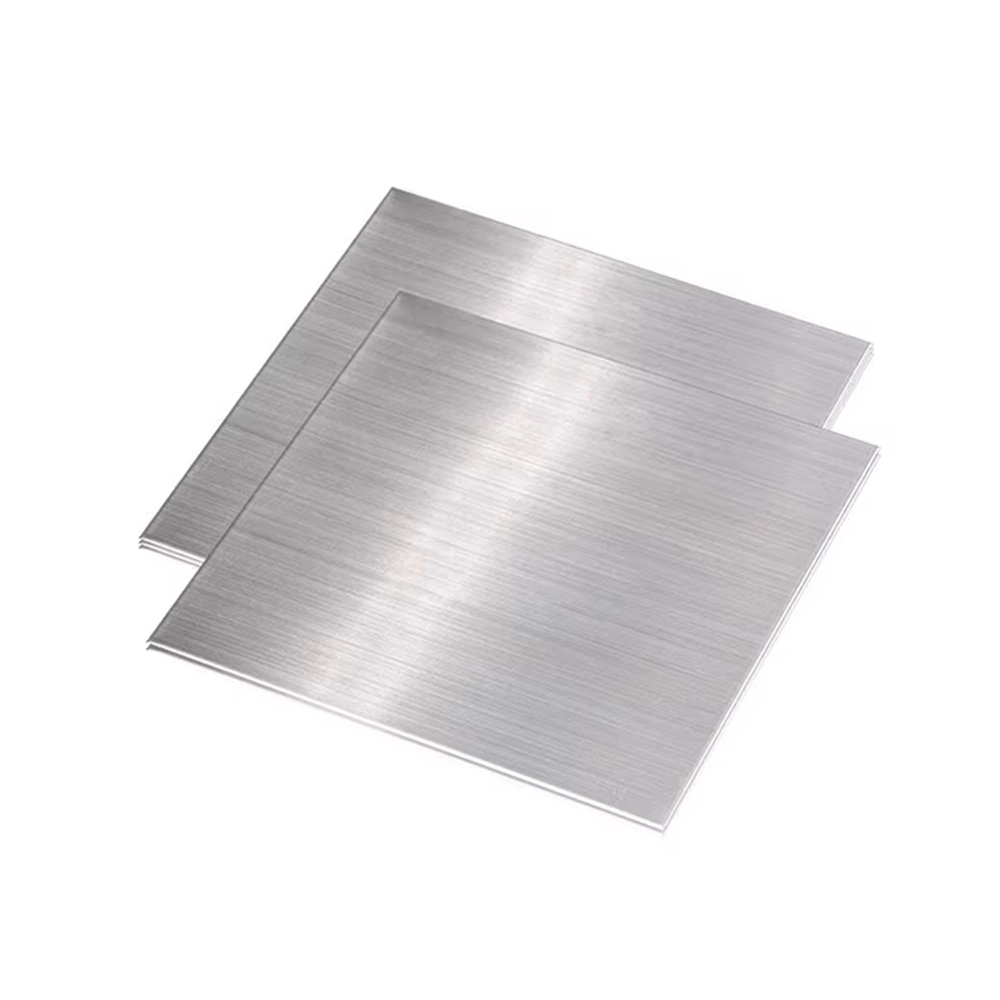

7. No. 3 & No. 4 Finishes

No. 3 finish is a coarse satin finish, while No. 4 finish is a brushed, satin-smooth finish. Both are achieved via abrasive polishing.

Features:

- Uniform brushed appearance

- Less reflective than mirror finishes

- Conceals scratches effectively

Applications:

- Commercial kitchens

- Elevator interiors

- Architectural panels

Learn more about stainless steel applications in home appliances.

8. No. 6 Finish

The No. 6 finish is a dull, matte surface with low reflection, achieved through grinding with fine abrasives.

Features:

- Smooth but non-reflective

- Resists corrosion and fingerprint marks

Applications:

- Architectural cladding

- Decorative panels

9. No. 7 Finish

No. 7 finish is a highly polished mirror finish, often a step below the ultra-reflective No. 8.

Features:

- Smooth, glossy surface

- Attractive for decorative applications

- Can be combined with protective coatings

Applications:

- Jewelry components

- Architectural decorative surfaces

10. No. 8 Finish

No. 8 finish is the most reflective, mirror-like finish, produced by extensive buffing and polishing.

Features:

- High reflectivity

- Premium aesthetic appeal

- Excellent corrosion resistance

Applications:

- Luxury elevators

- Decorative panels

- Art installations

For a complete production guide, visit Stainless Steel Coil Production Process Guide.

Other Finishes

Other stainless steel finishes include specialty coatings or textures such as sandblasting, shot peening, or patterned embossing. These are used to enhance appearance, increase friction, or improve durability.

Custom Finishes

Many industries require custom finishes tailored to specific aesthetic or functional needs. Custom finishes may involve:

- Unique polishing techniques

- Etching or laser treatments

- Coatings to improve scratch resistance

Request specialized finishes via Stainless Steel Foil Contact.

TR (Temper Rolled) Finish

TR finish involves light cold rolling that produces a smooth, dull surface with improved strength.

Applications:

- Industrial machinery

- Structural panels

Architectural Finish

Architectural finishes are designed for visual appeal and durability. They include combinations of polishing, brushing, and coating to meet specific aesthetic requirements.

Applications:

- Building facades

- Interior panels

- Elevators and handrails

What is the Surface Roughness of Stainless Steel?

Surface roughness measures the microscopic peaks and valleys on a metal surface. It is denoted by Ra (average roughness) in micrometers.

| Finish Type | Typical Ra (µm) | Notes |

|---|---|---|

| Mill Finish | 0.8 – 1.6 | Coarse industrial applications |

| No. 2B | 0.2 – 0.4 | Smooth, ready for fabrication |

| No. 4 (Brushed) | 0.4 – 0.8 | Common in kitchens and appliances |

| No. 8 (Mirror) | 0.05 – 0.1 | Highly polished decorative applications |

Surface roughness impacts corrosion resistance, cleaning efficiency, and appearance. For detailed technical data, visit Stainless Steel Strip for Stamping Operations.

Summary

Understanding stainless steel surface finishes is essential for selecting the right material for industrial, architectural, and decorative projects. From basic mill finishes to high-gloss mirror finishes, each option offers unique benefits for performance and aesthetics. Whether you are manufacturing consumer goods, building interiors, or precision components, matching the correct finish ensures optimal results.

For further exploration, you can browse Stainless Steel Foil Products or read more insights on our blog.

FAQs

Why is surface finish important for stainless steel?

Surface finish affects corrosion resistance, aesthetics, cleanability, and suitability for fabrication.

What is the difference between No. 2B and No. 4 finishes?

No. 2B is smooth and reflective but not brushed. No. 4 is a brushed satin finish, commonly used in kitchens and architectural applications.

Can stainless steel finishes be customized?

Yes, custom finishes can be applied for aesthetic or functional purposes through polishing, coating, or etching.

What is the best finish for food processing equipment?

Finishes like No. 4 or bright annealed (BA) are preferred for hygiene, corrosion resistance, and ease of cleaning.

Where can I buy high-quality stainless steel strips and coils?

You can explore a wide range of products on Stainless Steel Foil including 304 stainless steel strips.