Stainless steel foil represents one of the most versatile and technologically advanced materials in modern manufacturing. This ultra-thin, high-performance material combines the strength and durability of stainless steel with remarkable flexibility, making it indispensable across dozens of industries. From aerospace components to medical devices and consumer electronics, stainless steel foil delivers unmatched performance where ordinary materials fail.

Understanding Stainless Steel Foil

Stainless steel foil consists of thin sheets of stainless steel, typically ranging from 0.02 mm to 0.6 mm in thickness. Unlike standard steel sheets, foil undergoes specialized cold rolling and annealing processes to achieve its exceptional thinness while maintaining structural integrity. The material belongs to the austenitic stainless steel family, known for its non-magnetic properties, high corrosion resistance, and excellent formability.

The production of stainless steel foil requires precision engineering to ensure consistent thickness, surface finish, and mechanical properties. Manufacturers carefully control the rolling process to prevent defects while achieving the desired thinness. For applications requiring extreme precision, ultra-thin stainless steel foil (below 0.1 mm) offers additional benefits in weight reduction and flexibility.

Explore our full range of stainless steel foil products to find the ideal solution for your needs.

Types of Stainless Steel Foil

Different grades of stainless steel foil serve distinct purposes based on their chemical composition and properties. Below are the most common types:

304 Stainless Steel Foil

The 304 grade represents the most widely used stainless steel foil, containing 18% chromium and 8% nickel. This composition provides excellent corrosion resistance, making it suitable for:

- Food processing equipment

- Chemical containers

- Architectural trim

- Pharmaceutical applications

Learn more about 304 stainless steel foil and its packaging solutions here.

316 Stainless Steel Foil

316 stainless steel foil includes molybdenum (2-3%), significantly enhancing its resistance to chlorides and acidic environments. Key applications include:

- Marine equipment

- Medical implants

- Chemical processing plants

- Coastal architectural elements

Discover the advantages of 316 stainless steel foil for demanding environments.

309 Stainless Steel Foil

Designed for extreme heat resistance, 309 stainless steel foil contains higher chromium and nickel content, making it ideal for:

- Furnace components

- Heat exchangers

- High-temperature gaskets

- Thermal insulation systems

Ultra-Thin Stainless Steel Foil (0.02–0.07 mm)

This specialized foil serves precision applications where minimal thickness is required:

- Flexible printed circuits

- Microelectronics shielding

- Thin-film sensors

- Medical stents

Chemical Composition Comparison of Stainless Steel Foil Grades

The following table presents the chemical composition specifications for the primary stainless steel foil grades. These values represent maximum percentages unless a range is indicated.

| Grade | Carbon | Manganese | Silicon | Sulfur | Chromium | Nickel |

| 301 | 0.15 max | 2.0 max | 1.0 max | 0.03 max | 16-18% | 6-8% |

| 304 | 0.08 max | 2.0 max | 1.0 max | 0.03 max | 18-20% | 8-10.5% |

| 304L | 0.03 max | 2.0 max | 1.0 max | 0.03 max | 18-20% | 8-12% |

| 316 | 0.08 max | 2.0 max | 1.0 max | 0.03 max | 16-18% | 10-14% |

| 316L | 0.03 max | 2.0 max | 1.0 max | 0.03 max | 16-18% | 12-15% |

Product Forms: Rolls, Sheets, and Tapes

Stainless steel foil reaches end users in several distinct product forms, each suited to specific applications and manufacturing processes. Understanding these forms helps buyers specify the correct product for their needs and optimize their production workflows.

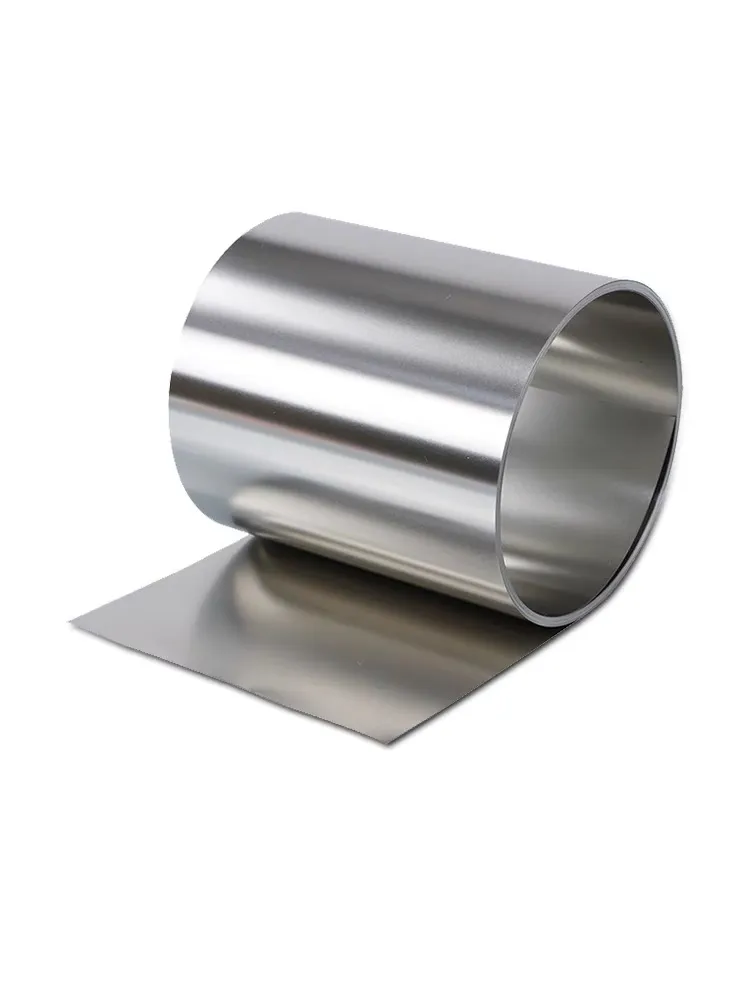

Stainless Steel Foil Rolls: The Primary Form

The stainless steel foil roll represents the most common delivery format for this material. Manufacturers wind continuous lengths of foil onto cores, creating coils that range from narrow strips of 2mm width to broad sheets reaching 610mm (24 inches) across. Roll lengths vary based on thickness and width, with thinner gauges naturally producing longer rolls for a given coil weight.

Roll form offers significant advantages for high-volume manufacturing operations. Automated feeding systems can draw material directly from rolls, minimizing handling and reducing waste from cut edges. The continuous nature of roll stock allows uninterrupted production runs, increasing throughput and reducing unit costs.

Slitting services allow manufacturers to supply stainless steel foil rolls in any width required by the application. Production equipment can slit master coils into precise widths from 2mm to the full strip width. This flexibility eliminates waste from trimming oversized material and ensures compatibility with specific machine requirements.

Stainless Steel Foil Tape: Adhesive-Backed Solutions

Stainless steel foil tape combines the performance characteristics of stainless steel foil with pressure-sensitive adhesive backing. This product form simplifies installation for many applications, eliminating the need for mechanical fasteners, welding, or separate adhesive systems.

The tape format finds extensive use in shielding applications where electromagnetic interference (EMI) or radio frequency interference (RFI) must be controlled. The conductive stainless steel surface provides an effective barrier against electromagnetic energy, while the adhesive backing ensures reliable contact with equipment housings and cable assemblies.

HVAC duct sealing represents another major market for stainless steel foil tape. The material seals joints and seams in ductwork, preventing air leakage while withstanding the temperature extremes common in heating and cooling systems. The corrosion resistance of stainless steel ensures long service life even in humid conditions that would degrade aluminum alternatives.

Ultra Thin Stainless Steel Foil: Precision Applications

Ultra thin stainless steel foil refers to material at the extreme end of the thickness spectrum, typically measuring 0.05mm (0.002 inches) or less. Producing these gauges requires specialized equipment and exceptional process control, as even minor variations become significant at such thin dimensions.

The thinnest commercially available foils reach gauges of 0.015mm (0.0006 inches), approaching the practical limits of cold rolling technology. These materials serve highly specialized applications in electronics, sensors, and research where the unique properties of stainless steel must be delivered in minimal thickness.

Battery manufacturing has emerged as a significant growth market for ultra thin stainless steel foil. The material serves as current collectors in certain battery designs, offering advantages over traditional copper or aluminum in terms of corrosion resistance and electrochemical stability. As battery technology advances, demand for precision stainless steel foils continues to expand.

Applications of Stainless Steel Foil

Industrial Uses

- Electronics: EMI/RFI shielding, flexible circuits, battery components

- Automotive: Exhaust gaskets, heat shields, sensor housings

- Aerospace: Thermal blankets, lightweight structural components

Medical & Pharmaceutical

- Surgical instruments

- Implantable devices

- Sterilizable packaging

Consumer & Architectural

- Decorative laminates

- Appliance linings

- Specialty packaging

Energy Sector

- Fuel cell components

- Solar panel substrates

- Nuclear shielding

Stainless Steel Foil Roll & Tape Solutions

For industrial users, stainless steel foil rolls provide cost-effective material in bulk quantities. Custom slitting services allow precise width configurations from 2mm to 500mm.

Stainless steel foil tape combines the material’s benefits with pressure-sensitive adhesive for:

- HVAC duct sealing

- EMI shielding repairs

- High-temperature masking

How to Select and Purchase Stainless Steel Foil

Selecting the right stainless steel foil requires careful consideration of application requirements, material specifications, and supplier capabilities. This section provides guidance for engineers and procurement specialists navigating the purchasing process.

Defining Your Requirements

Before requesting quotations, buyers should clearly define their technical requirements. Key specifications include the grade, thickness, width, quantity, surface finish, and mechanical properties needed for the application. Incomplete specifications lead to misquotes, delays, and potential delivery of unsuitable material.

If you are uncertain about specific parameters such as hardness or tensile strength requirements, communicate your intended application to the supplier. Experienced manufacturers can recommend appropriate specifications based on how the material will be used. Many suppliers, including Myriad, Inc., offer free testing services for existing materials to determine exact specifications for replacement orders.

Tolerance requirements deserve particular attention. Standard manufacturing tolerances may be acceptable for many applications, while precision uses require tighter control. Specifying unnecessarily tight tolerances increases costs without benefit, while tolerances too loose for the application cause field failures.

Evaluating Suppliers

Quality certifications provide objective evidence of supplier capability. Look for manufacturers operating under ISO 9001 quality management systems, which establish standardized processes for consistent product quality. Additional certifications relevant to specific industries, such as AS9100 for aerospace or ISO 13485 for medical devices, indicate specialized capability.

Manufacturing equipment and capacity affect both capability and lead times. Suppliers with modern rolling mills and proper packaging facilities can produce high-quality foil in thinner gauges with tighter tolerances than those limited to older equipment. Adequate inventory and production capacity ensure reliable delivery without excessive lead times.

Technical support capability separates premium suppliers from commodity sources. The ability to consult on material selection, provide testing services, and resolve quality issues adds value beyond the basic product. Suppliers who invest in engineering support demonstrate commitment to customer success.

Sample Testing and Qualification

Before committing to production quantities, request samples for testing in your application. Reputable suppliers provide sample material at no charge to qualified customers. Test the material under actual operating conditions to verify performance before specifying the supplier for production orders.

Document your qualification testing and retain records for reference. Should quality issues arise in production, historical test data provides a baseline for comparison. Established relationships with qualified suppliers reduce the risk of quality problems and simplify resolution when issues occur.

For assistance with material selection or to request samples and quotations, contact our technical team. Our engineers can help you identify the optimal stainless steel foil solution for your specific requirements.

Conclusion

Stainless steel foil stands as a material of unparalleled versatility, combining the strength of steel with the flexibility required for modern technological applications. From 304 stainless steel foil for general use to specialized 316 and ultra-thin variants, this material solves engineering challenges across industries.

For technical specifications or purchasing guidance, visit our product page or contact our team. To learn more about stainless steel’s fundamental properties, refer to this comprehensive resource.

FAQs

Q: How does 304 foil differ from 316 foil?

A: 316 contains molybdenum for superior chloride resistance, while 304 offers general-purpose corrosion protection.

Q: Can stainless steel foil be used for food contact?

A: Yes, grades like 304 and 316 are FDA-compliant for food processing.

Q: What’s the thinnest available stainless steel foil?

A: Precision foils down to 0.02mm are produced for specialized applications.

Q: How should stainless steel foil be stored?

A: Keep in dry conditions, preferably in original packaging to prevent surface scratches.

Q: Is custom perforation or embossing available?

A: Yes, secondary processing can create custom patterns for filtration or decorative uses.