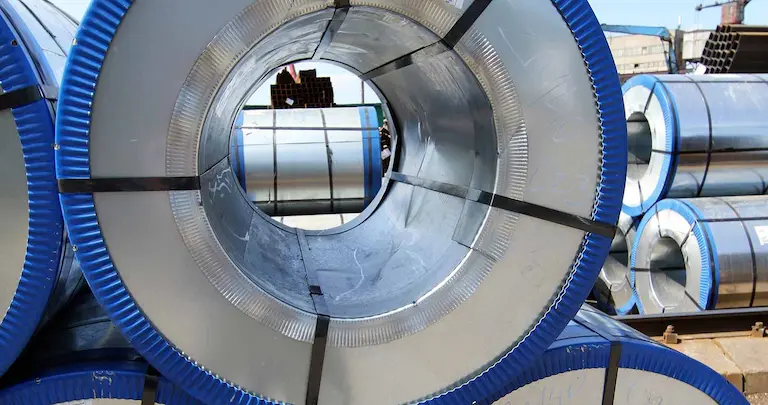

In 1996, we established a factory in NINGBO, a coastal city with well-developed transportation. Ningbo has an excellent geographical location, only an hour’s drive from China’s largest deep-water port. Secondly, we specialize in cold-rolled stainless steel coils with high hardness and high tensile strength, including 304 ss Stainless Steel.

-Because YAOYI has rich equipped

We have advanced stainless steel production equipment. Our R&D team combines numerical control instruments and precision cold rolling mills through technological transformation and can control the tolerance within 0.001mm. At the same time, because many customers have special “negative tolerance” requirements, YAOYI can also do this for you. Furthermore, we also have 4 edge scraping machines and slitting machines. The edge scraper can remove burrs from your stainless steel coils to protect the safety of production workers. The slitting machine can divide the coils to the narrowest 3mm width according to your requirements.

-Because we have complete production lines

You can inquire and purchase various cold-rolled stainless steel coils such as 201, 301, 302, 304, 304L, 310S, 316L, and 430 from us.

Our thickness can be from 0.05mm to more than 2mm.

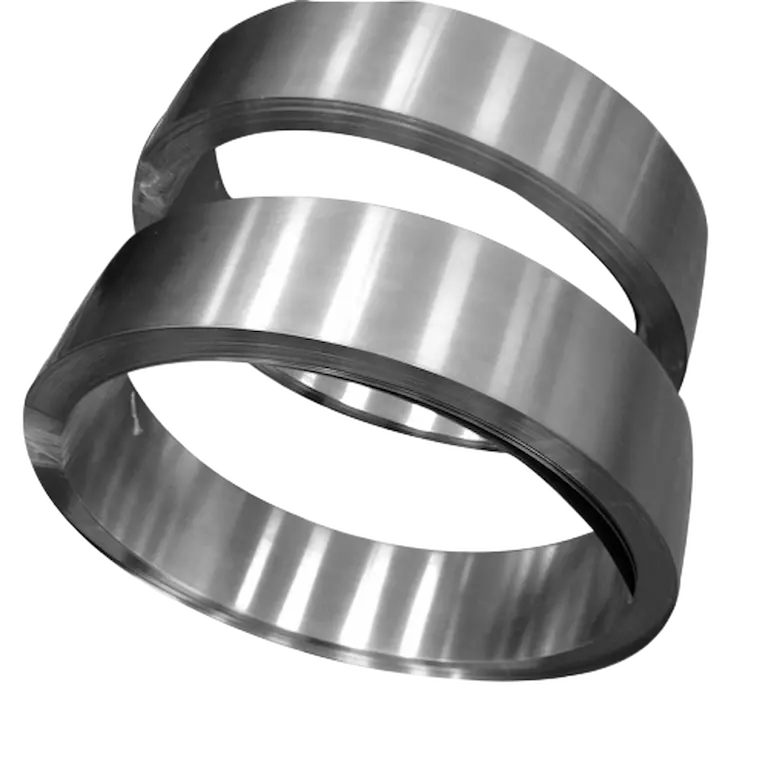

At the same time, we can make annealed, 1/2 hard, 3/4 hard, and more than 500 hardness stainless steel strips.

If you have any questions about 304 Stainless Steel, please contact us.

The 304 ss stainless steel is a T 300 Series austenitic. It consists of at least 18% chromium and 8% nickel, with a 0.08% carbon cap, chromium, and nickel austenitic alloy.

Furthermore, the austenitic 304 ss stainless steel is the most flexible and commonly used of the austenitic 304 stainless steel due to its chromium-nickel content and low carbon. Its alloys are all variants of the 18% chromium, 8% nickel austenitic alloy. Kind 304 ss is resistant to rust, corrosion, and wear. Corrosion-resistant electrical enclosures, auto molding, and trim, wheel covers, kitchen appliances, hose clamps, exhaust manifolds, stainless fixtures, water bins, pressure vessels, and plumbing all use 304 ss .

Furthermore, owing to its excellent corrosion resistance and value, 304 ss stainless steel is the most common kind of stainless steel used worldwide. It contains between 16 and 24% chromium, up to 35% nickel, and trace amounts of carbon and manganese.

304 stainless steel is most often stainless steel with a shape of 18-8 (18/8), including 18% chromium and 8% nickel.

304 stainless steel is the most popular type of stainless steel in the world because of the excellent corrosion resistance and value.

The stainless steel 304 ss can resist corrosion from most oxidizing acids. Due to its hardness, 304 ss stainless steel is easy to sanitize and also ideal for use in kitchens and food. It is also used in furnishings for architecture, decoration, and location.

However, 304 ss stainless steel has one flaw: it is vulnerable to corrosion from chloride solutions or salty conditions such as the coast. Chloride ions can cause pitting, or localized corrosion, that can extend under protective chromium barriers and compromise internal structures. Solutions with as little as 25 ppm sodium chloride will begin to corrode.

Also, there is also no substantial difference between the SFE of 304 and 304L. As a result, the stress corrosion cracking propensity of simple 304 ss stainless steel in solution annealed state is not thought to vary from that of its low carbon varieties. The inclusion of 2–3 wt percent molybdenum in the alloy strengthens the passive film.

This is achieved by enriching the passive film with more chromium, making it more impossible to crack by an offensive ion. However, molybdenum is not integrated into the passive form. This and the slightly higher stacking fault energy is also the result of superior stress corrosion resistance to stainless steel sodium chloride solutions of the type 304 ss over the type 304/304L stainless steel.

Thus, heat therapy was conducted at 750 °C for 2 hours and 500 °C for 24 hours and the heat therapy solution was carried out at 1100 °C for 1 hour. The reactivation ratio of the sensitized material was 29.3%. At 288°C, a tensile measurement produced an offset stress of 0.2 percent of 140 MPa.

Also, there is also no substantial difference between the SFE of 304 and 304L. As a result, the stress corrosion cracking propensity of simple 304 ss stainless steel in solution annealed state is not thought to vary from that of its low carbon varieties. The inclusion of 2–3 wt percent molybdenum in the alloy strengthens the passive film.

This is achieved by enriching the passive film with more chromium, making it more impossible to crack by an offensive ion. However, molybdenum is not integrated into the passive form. This and the slightly higher stacking fault energy is also the result of superior stress corrosion resistance to stainless steel sodium chloride solutions of the type 304 ss over the type 304/304L stainless steel.

Thus, heat therapy was conducted at 750 °C for 2 hours and 500 °C for 24 hours and the heat therapy solution was carried out at 1100 °C for 1 hour. The reactivation ratio of the sensitized material was 29.3%. At 288°C, a tensile measurement produced an offset stress of 0.2 percent of 140 MPa.

1.Products of forming and welding

2.Resistance to corrosion/oxidation by chromium content

3.Deep standard of drawing

4.Excellent power, even at cold temperatures (extremely cold temperatures).

5.Properties of low temperature respond well to cold hardness work.

6.Easy to clean, easy to make, and beautiful.

The most versatile and widely used of all stainless steels is the stainless steel 304 ss. It offers the best all-around performance of 304 stainless steel at a reasonably low cost due to its chemical composition, mechanical properties, welder, and corrosion/oxidation resistance. It also has excellent low-temperature properties and responds well to cold hardness. If intergranular corrosion can occur in the heat zone, SS 304L is recommended.

The temperature ranges between 1010 and 1120°C and can be easily refrigerated in air or water. The highest corrosion resistance is achieved when the final rinsing temperature is over 1070°C and the cooling is fast.

For 1 hour with little risk of sensitization, 304 ss of stainless steel can be stressed relief at 450-600 oC. A temperature of 400 o C should be lower than that of stress relief.

1.The forging and pressing original is between 1150 and 1260°C.

2.The temperature is between 900 and 925oC.

3.So it is essential to follow all hot-working operations by annealing.

Remember to soak it to ensure uniformity of temperature is longer for 304 ss stainless steel than for carbon steels at approximately 12 times.

The steel 304 is extremely robust and ductile and ready to be manufactured using classical methods. All common operations are bending, forming, deep drawing, and disturbing.

Since the 304 ss stainless steel contains 18% chromium, it is resistant to many corrosive conditions. Because the 8% nickel, it contains is austenite in the structure. Because of its tough, ductile structure, Grade 304 is superior foresight and manufacturing properties.

Steel is used in most applications because of its corrosion resistance, which ensures a long-lasting look and service life. Steel is ideal for a variety of applications due to its ease of cleaning and preserving a sanitary surface.

The most common finish is a brightly colored, 1 hot rolled, 2D hot rolled, 2B cold-rolled, skin passed, N4 polished, and BA is the most common.

A surface with white polyethylene (PE) film is also available with flat items. Deep drawing protection is also available with black polyvinyl chloride (PVC) or black PVC hard forming protection.

In many settings, the range 304 stainless steel is very resistant to corrosion.

Furthermore, in the majority of environments, 304 ss of stainless steel works well except for marine environments or areas of high industrial waste. The best look is to maintain where the design even allows rain to wash the surface or where dirt is often washed out from the steel.

Furthermore, in some cases in drinking water, the stainless steel of 304 ss was of excellent service. Higher concentrations of chloride can cause corrosion in the tank and crevice, with the upper limit being considered 200 ppm.

Moreover, the 304 ss of rustic steel is usually not of assistance in marine water as there is a chance that sediments, precipitation, and foliation can result in crevice corrosion.

The austenitic alloy stainless steel 304 ss retains the ductile fracture mode and high absorbed energy in impact tests at cryogenic temperatures (-200°C).

The most popular type is AS1210, Pressure Vessels, which requires grade 304 ss stainless steel to be used up to 800°C. For 304H, this standard allows for higher geometry stresses at all temperatures.

For grade 304 in the air, the maximum operating temperatures are 870°C for sporadic service and 925°C for continuous service.

Stainless steel 304 ss is widely used in food appliances where bacteria removal is important. Many other materials have a cleaner finish than stainless steel 304 ss.

304 ss stainless steel can be safely used for standard sheet metal operation methods, except for the oxygen cutting. Cutting plasma is normal. 304 ss stainless steel is exceptionally deep drawing capacity.

At temperatures above 925°C, type 304 ss stainless steel is one of the simpler austenitic stainless steel to forge.

Simple to machine, though harder than carbon steel, is stainless steel 304. For machine class 304, more power is required. It is essential to reduce the speed of the cutting, increase feed and increase the tools and equipment. 304 is roughly 60% more usable than the sweetened free-cutting steel of AISI B1112. A 304 ss stainless steel free-machining variant can be obtained as a rod.

The solution is rectified at 1065-1120 °C, followed by a fast refreshment that prevents chromium carbide precipitation. The heat treatment of 304 ss of stainless steel can’t harden. Because of the high ductility of 303 stress relief is rarely needed.

Most techniques such as GTAW/TIG, GMAW/MIG/MAG, MMAW/stick, and SAW, without preheating, post-heat, or interpass temperature control, shall weld stainless steel grades 304 ss. The corrosion resistance and strength can be maintained by welding with standard austenitic metals such as 308, 308L, 309L, 316, or 316L. Weld metals for welding grade 304 stainless steel to itself or most other austenitic classes have been prequalified to AS1554.6:1994 for grades 308 and 308Si.

1.Storage tanks

2.Hardware and attachments finishing (screws, nuts, bolts, plates, handles)

3.Cups and cups

4.House sinks and drains components

5.Architectural and decorative indoor equipment

6.Sculptures, sconces, panels, etc.

7.Tubing of equipment

8.Appliances for the home

9.Mining, chemical, cryogenic, beef, dairy, and pharmaceutical sectors all use process machinery.

Although 304 stainless steel has excellent corrosion resistance, it is not completely immune to rust. Under certain conditions, such as exposure to chlorides, high temperatures, or a lack of oxygen, 304 stainless steel may corrode or rust. To prevent rust, ensure proper cleaning and maintenance, and consider using a higher grade like 316 in more aggressive environments.

18/8 stainless steel is another term used for 304 stainless steel. The “18/8” designation refers to the approximate chromium (18%) and nickel (8%) content in the steel, providing it with excellent corrosion resistance and formability. Both terms are interchangeable and describe the same material.

To get the best price when purchasing 304 ss stainless steel, consider ordering in bulk, negotiating with the supplier, and comparing prices from different manufacturers. Also, consider the total costs, including shipping and handling, taxes, and any potential costs related to quality issues.

Reliable manufacturers of 304 ss stainless steel can be found through industry directories, trade shows, and online marketplaces. Look for manufacturers with good reputations, quality certifications, and a history of serving customers in your specific industry or region.

Absolutely, let’s dive a bit deeper into the differences between stainless steel 304 and 316.

Composition: Both 304 and 316 stainless steels are part of the austenitic family, meaning they have a face-centered cubic crystal structure. However, their chemical compositions vary. Stainless steel 304 typically contains 18% chromium and 8% nickel (hence it’s also known as 18/8 stainless), while 316 stainless steel contains 16% chromium, 10% nickel, and 2% molybdenum. The addition of molybdenum in 316 grade improves its resistance to certain types of corrosion.

Corrosion Resistance: Both 304 and 316 offer excellent corrosion resistance. However, 316’s molybdenum addition makes it more resistant to corrosive environments, especially those involving salt or chemicals such as chlorides. This makes 316 a better choice for applications like marine environments or chemical processing where corrosive elements are present.

Cost: Generally, 304 ss stainless steel is more affordable than 316 due to its lower molybdenum content. If your project doesn’t require the additional corrosion resistance provided by 316, using 304 can be a cost-effective choice.

Heat Resistance: Both 304 and 316 stainless steels have strong resistance to oxidation and maintain their structural integrity at high temperatures. But their maximum temperatures differ slightly, with 304 ss stainless steel becoming more susceptible to changes in its properties at temperatures above 870°C, whereas 316 can withstand up to 925°C.

Applications: The differences in properties between 304 and 316 lead to differing applications. 304 ss stainless steel is commonly used in domestic kitchens and appliances, sinks, and heat exchangers, while 316 is often used in marine applications, chemical processing, and high-saline environments.

Weldability: Both grades have excellent weldability, but 316’s superior corrosion resistance means it’s often the preferred choice for welded applications in challenging environments.

In conclusion, while 304 and 316 stainless steels are similar in many aspects, the choice between the two will depend on the specific requirements of your project, including cost considerations and the environment in which the material will be used.

Austenitic Stainless Steels: These are the most widely used type of stainless steel and have a face-centered cubic crystal structure. They are non-magnetic and have excellent formability and weldability. Key grades include:

304: The most common grade; excellent formability and weldability and good resistance to corrosion.

316: Contains molybdenum for better resistance to corrosive environments than 304.

321: Stabilized with titanium for applications at elevated temperatures.

Ferritic Stainless Steels: These steels have a body-centered cubic crystal structure and are magnetic. They generally have good formability and corrosion resistance and are often used in automotive applications. Key grades include:

430: A very widely used general-purpose grade with good corrosion resistance.

409: A low-cost option with reduced corrosion resistance but excellent formability. Often used in automotive exhaust systems.

Martensitic Stainless Steels: These steels are high-strength, hard, and wear-resistant but are less resistant to corrosion compared to austenitic and ferritic grades. They are magnetic and can be heat treated to improve their hardness. Key grades include:

410: Basic martensitic grade with good hardness and moderate corrosion resistance.

440C: Higher carbon content gives this grade high hardness and abrasion resistance.

17-4PH: Provides high strength combined with good corrosion resistance and is widely used for a variety of applications.

The exact grade of stainless steel used will depend on the specific properties required, including strength, corrosion resistance, magnetic permeability, cost, and heat resistance.

Stainless steel 304, with its excellent forming and welding characteristics, is one of the most commonly used stainless steels. Here are some of its typical applications:

Kitchen Equipment and Appliances: 304 ss stainless steel is widely used in kitchen environments due to its high corrosion resistance and ability to be sanitized. It is used in a variety of kitchen equipment, including cookware, cutlery, and kitchen sinks. In addition, it’s found in appliances like refrigerators and dishwashers.

Architectural Paneling, Trim and Accents: Thanks to its excellent corrosion resistance and aesthetic appeal, stainless steel 304 is a popular choice for architectural applications.

Food Processing Equipment: The food and beverage industry often utilizes 304 ss stainless steel for its resistance to corrosion and ease of cleaning. Equipment such as conveyors, grinders, sinks, and reusable containers are often made from this grade.

Chemical Containers, Including for Transport: Due to its low reactivity, 304 ss stainless steel is a common choice for making and storing chemicals, including both industrial chemicals and consumer packaged goods.

Heat Exchangers: 304 stainless steel’s good heat-resisting properties make it a good option for heat exchanger tubes.、

Plumbing Materials: From pipes and tubes to fittings, 304 ss stainless steel is commonly used in plumbing applications.

Automotive sector: It’s also used in various parts of automobiles and aircraft, largely due to its strength and resistance to rust.

Medical equipment: 304 stainless steel’s resistance to corrosion and staining, as well as its low maintenance, makes it an ideal material for many applications in the medical field.

The exact applications of 304 ss stainless steel will depend on the environment and specific requirements of the task at hand.

Posco (South Korea): Founded in 1968, Posco is one of the largest steel producers in the world, supplying a wide range of products including 304 stainless steel. Website: https://www.posco.com/

ArcelorMittal (Luxembourg): ArcelorMittal is the world’s largest steel and mining company and produces various types of stainless steel, including 304. Website: https://www.arcelormittal.com/

Nippon Steel Corporation (Japan): Nippon Steel is a top-rated steelmaker in the world. It produces a wide variety of steel types, including 304 stainless steel. Website: https://www.nipponsteel.com/

Jindal Stainless Ltd. (India): Part of the OP Jindal group, this company is one of the largest stainless steel manufacturers in India. They produce and sell a variety of stainless steel products, including 304 grade. Website: https://www.jindalstainless.com/

Outokumpu (Finland): Outokumpu is one of the largest producers of stainless steel in Europe, offering a variety of products including 304 stainless steel. Website: https://www.outokumpu.com/

TISCO (Taiyuan Iron & Steel Co. Ltd.) (China): This is China’s largest stainless steel producer and offers a wide range of products, including 304 stainless steel. Website: http://www.tiscn.com/

Please note that this list could change due to industry dynamics like mergers, acquisitions, and market trends. It’s always a good idea to do thorough research or consult a sourcing expert when looking for suppliers.

When sourcing 304 ss stainless steel from a factory, several factors should be taken into consideration to ensure that you are obtaining high-quality materials that meet your requirements. Here are some key factors to consider:

Quality Standards: Ensure that the factory adheres to strict quality standards, such as ISO 9001 or other internationally recognized certifications. This will give you confidence in the quality and consistency of their products.

Material Specifications: Be clear about your specific requirements for the 304 stainless steel, such as dimensions, tolerances, surface finish, and any additional processing or treatment needed. Make sure the factory can meet these specifications.

Factory Reputation: Research the factory’s reputation within the industry and look for reviews or testimonials from previous customers.

Lead Time: Evaluate the factory’s lead time for manufacturing and delivery, ensuring it aligns with your project timeline. Longer lead times could potentially delay your project or increase costs due to storage and handling.

Logistics: Consider the factory’s location and transportation options, as this can impact shipping costs and delivery time. Make sure the factory can provide appropriate packaging and shipping methods to protect the materials during transportation.

Customization Capabilities: If your project requires custom or specialized 304 ss stainless steel products, ensure the factory has the necessary capabilities, equipment, and expertise to meet these requirements.

After-sales Support: Evaluate the factory’s after-sales support, including their return or exchange policy and their willingness to address any quality issues that may arise after the materials have been delivered.

Environmental and Social Responsibility: Choose a factory that follows environmentally friendly practices and has a strong commitment to social responsibility. This can include responsible sourcing of raw materials, energy-efficient manufacturing processes, and fair labor practices.

Communication and Customer Service: Establish a good line of communication with the factory to ensure that they can address your needs and concerns promptly. Good customer service is crucial for successful collaboration and long-term business relationships.

Taking the time to research and evaluate potential factories thoroughly can help you find a reliable partner that can provide high-quality 304 ss stainless steel materials for your project, while also meeting your budget and timeline requirements.

Wholesaling 304 ss stainless steel involves purchasing large quantities of the material from manufacturers or distributors and then reselling it to retailers or other businesses. To start wholesaling 304 stainless steel, follow these steps:

This includes identifying potential customers, analyzing competitors, and determining market trends. This information will help you make informed decisions about your product offerings, pricing strategies, and target audience.

Source Suppliers: Find reliable manufacturers or distributors that supply high-quality 304 ss stainless steel products. Consider factors like quality standards, lead times, customization capabilities, pricing, and location when choosing a supplier. Establishing strong relationships with your suppliers can help ensure a consistent supply of materials and favorable pricing.

Product Selection: Choose the specific 304 ss stainless steel products you want to offer, such as sheets, coils, tubes, or bars. Consider the needs of your target customers and select products that cater to those needs. Be prepared to offer a variety of sizes, thicknesses, and finishes to accommodate different applications and requirements.

Inventory Management: Develop an inventory management system to track your stock levels, monitor sales trends, and predict demand. This will help you maintain optimal inventory levels, prevent stockouts, and minimize storage costs.

Pricing Strategy: Determine your pricing strategy based on factors like cost of goods, market demand, competitor pricing, and your target profit margins.

Marketing and Promotion: Develop a marketing plan to promote your 304 ss stainless steel wholesale business. This can include creating a website, using social media, attending industry trade shows, and networking with potential customers. Make sure to highlight the benefits and features of your products, as well as your competitive pricing and excellent customer service.

Sales Channels: Establish sales channels to reach your target customers. These can include online platforms like Alibaba or eBay, direct sales to local retailers or manufacturers, or partnerships with other wholesalers. Consider offering incentives like volume discounts or flexible payment terms to attract larger customers.

Customer Service and Support: Provide excellent customer service and support to build strong relationships with your customers. This includes offering prompt communication, addressing any issues or concerns, and providing after-sales support. Satisfied customers are more likely to become repeat buyers and refer your business to others.

Legal and Regulatory Compliance: Ensure that your wholesale business complies with all relevant laws, regulations, and industry standards. This may include obtaining necessary licenses or permits, maintaining proper records, and adhering to safety and environmental guidelines.

Continuous Improvement: Regularly evaluate your business performance and look for opportunities to improve and grow. This can include expanding your product offerings, adjusting your pricing strategy, or finding new sales channels.

By following these steps and focusing on offering high-quality 304 ss stainless steel products, competitive pricing, and excellent customer service, you can successfully establish and grow your wholesale business.

Several factors determine the price of 304 stainless steel, including:

Raw Material Costs: The primary raw materials used to produce 304 ss stainless steel are iron, chromium, nickel, and manganese. Fluctuations in the prices of these raw materials can have a significant impact on the overall cost of 304 stainless steel.

Manufacturing Costs: The production process of 304 ss stainless steel involves various steps, including melting, forming, heat treatment, and finishing. The costs of labor, energy, and equipment used in the manufacturing process can influence the final price of the material.

Supply and Demand: The balance between supply and demand in the market can affect the price of 304 stainless steel.

Quality and Specifications: The quality of the material, including surface finish, dimensions, and tolerances, can also influence the price. Higher quality materials or those with more stringent specifications may command a higher price due to the additional processing and quality control measures required during production.

Market Conditions: Global economic conditions, trade policies, and currency exchange rates can have an impact on the price of 304 stainless steel. For example, import tariffs or trade restrictions can lead to increased prices due to limited supply or higher production costs.

Transportation and Logistics: The cost of transporting and handling 304 stainless steel, including shipping, packaging, and warehousing, can also affect its price. Factors such as distance, shipping method, and fuel prices can influence transportation costs.

Volume Discounts: Purchasing larger quantities of 304 ss stainless steel can result in volume discounts, which can lower the per-unit price. Wholesalers and large manufacturers may benefit from these discounts due to their high purchasing volumes.

Competition: The level of competition among suppliers and manufacturers can also impact the price of 304 stainless steel. Higher competition can lead to lower prices as suppliers strive to attract customers with more competitive pricing.

As a buyer, understanding these factors can help you make informed decisions and negotiate better prices with suppliers.