304 Stainless Steel Foil Packaging for Transport Protection

When transporting 304 stainless steel foil, proper packaging is crucial to protect the delicate material from damage, moisture, and external

Stainless steel foil sheet is an incredibly versatile material with applications that touch nearly every aspect of our lives. From the varied types and grades like 304 and 316 to its use in heat treating, cooking, and beyond, this comprehensive guide dives into everything you need to know about stainless steel foil sheet. Whether you’re an industry professional or simply curious about this remarkable material, you’ll find insights, comparisons, quality standards, and practical tips to deepen your understanding and inspire your next project with stainless steel foil.

Stainless steel foil sheet is a versatile material available in various types and grades. These differences cater to specific applications and requirements.

The 200 series is known for its corrosion resistance. Common grades include:

The 300 series is famous for its austenitic structure. Key grades include:

Characterized by a ferritic and martensitic structure, the 400 series includes:

Some specialized grades cater to unique needs:

Choosing the right grade depends on factors like corrosion resistance, mechanical properties, and cost.

Stainless steel foil for heat treating is commonly used in industries requiring high-temperature resistance.

Stainless steel foil for cooking offers hygiene and ease of use, particularly in professional kitchens.

Understanding the types and grades of stainless steel foil sheet is essential for making an informed choice. The range of options ensures that the right material can be found for any specific need.

The manufacturing process begins with the selection of raw materials, including iron, nickel, chromium, and other alloys. High-quality materials ensure a superior final product.

The raw materials are melted in a furnace to form a molten alloy. The molten metal is then cast into slabs or ingots, which are the foundation for the stainless steel foil sheet.

The slabs or ingots undergo hot rolling, where they are heated and passed through rollers to reduce thickness. This stage prepares the metal for further processing.

The hot-rolled coils are further reduced in thickness through cold rolling. This process enhances the surface finish and dimensional accuracy.

Annealing is essential for relieving internal stresses and improving the material’s mechanical properties. The stainless steel is heated and then cooled slowly.

Surface finishing may include processes like pickling, polishing, or coating. These provide the desired appearance and corrosion resistance.

The stainless steel coils are cut and slit into the required dimensions to form stainless steel foil sheets. Precision instruments ensure accurate measurements.

Quality control measures are implemented throughout the manufacturing process. Advanced laboratory equipment tests the hardness, elongation, and chemical composition of the stainless steel foil sheet.

Stainless steel foil for heat treating is specifically manufactured to withstand high temperatures. The material’s properties are carefully controlled to meet industry standards.

The finished stainless steel foil sheets are packaged and delivered according to customer requirements. Proper packaging ensures safe transportation and handling.

Understanding the manufacturing processes of stainless steel foil sheet is vital for appreciating the material’s quality and performance. From raw material selection to final delivery, each step is carefully executed to provide the best stainless steel foil sheet.

Read more about the: 0.01~0.05mm Stainless Steel Foil Sheet Production: A Deep Dive

Stainless steel foil’s diverse applications include heat treating and cooking, highlighting its versatility and adaptability.

Stainless steel foil for heat treating plays a crucial role in various industries:

Utilized in turbine engines and heat shields, where it must withstand extreme temperatures.

Used in exhaust systems and engine components, providing heat resistance and structural integrity.

Employed in power plants for insulation and corrosion resistance.

Stainless steel foil for cooking offers unique advantages:

Chefs value stainless steel foil’s non-reactive nature, allowing it to maintain the purity of food flavors.

304 stainless steel foil sheet is popular in home kitchens due to its versatility and ease of cleaning.

Used in packaging to preserve freshness and provide a hygienic barrier.

316 stainless steel foil sheet’s corrosion resistance makes it suitable for surgical instruments and pharmaceutical equipment.

Stainless steel foil sheet’s aesthetic appeal enables its use in sculptures and decorative elements.

Stainless steel foil’s conductive properties make it essential in electronics, such as in connectors and shielding.

Stainless steel foil sheet is used in cladding and roofing, providing both aesthetics and durability.

Stainless steel is recyclable, and its use in various applications aligns with sustainability goals.

Different applications may require specific grades like 301 or 316 stainless steel foil sheet. Understanding the requirements ensures the selection of the right product.

Stainless steel foil’s applications in heat treating and cooking demonstrate its wide-ranging capabilities. Its performance in various domains illustrates why it’s an indispensable material in modern industry and daily life.

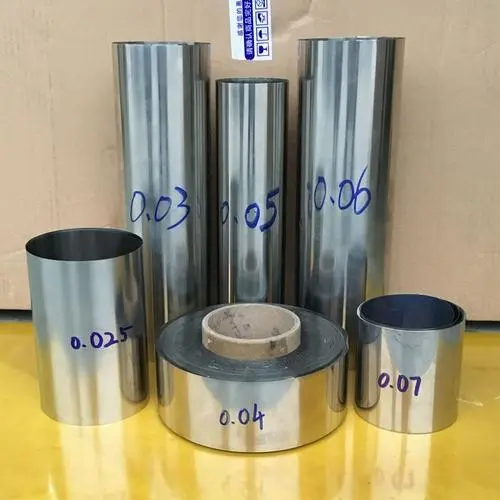

The thickness and quality of stainless steel foil sheet are vital parameters that directly impact its performance, durability, and functionality.

Thickness plays a significant role in defining the foil’s properties:

Thicker stainless steel foil sheets offer greater structural integrity and resilience to physical stresses.

Thinner stainless steel foil sheets provide more flexibility, making them suitable for intricate designs and applications.

Thickness influences the material’s ability to conduct heat, essential for applications like stainless steel foil for heat treating.

The weight of the foil is directly proportional to its thickness, affecting transportation and handling.

Quality defines the foil’s overall performance:

Choosing the right grade, such as 304 or 316 stainless steel foil sheet, ensures the desired properties for specific applications.

A quality surface finish enhances appearance and corrosion resistance.

Precision in thickness tolerance, often controlled using CNC systems, ensures uniformity and consistency across the foil sheet.

A quality stainless steel foil sheet maintains a precise chemical composition, offering predictable behavior and performance.

Adherence to international standards like ISO 9001 ensures that quality is maintained throughout the manufacturing process.

In cooking applications, thickness and quality dictate the foil’s ability to distribute heat evenly and resist wear and tear.

Higher thickness and quality may increase the cost but also offer better performance and longevity.

Quality stainless steel foil sheet contributes to sustainability through recyclability and energy efficiency.

Understanding the importance of thickness and quality in stainless steel foil sheet allows for informed decisions that align with specific needs and applications. Whether it’s the delicate artistry required in decoration or the robust performance needed in industrial applications, these parameters are key to success.

Read more about the: 0.01~0.05mm Stainless Foil: A Comprehensive Guide

316, 301, and 304 stainless steel foil sheets are popular grades, each with distinct properties and applications. Understanding their differences is crucial for selecting the right material.

316 grade offers distinct characteristics:

Known for excellent resistance to corrosion, especially in saltwater environments.

Contains molybdenum, enhancing its corrosion resistance.

Ideal for marine, pharmaceutical, and food processing industries.

301 grade provides specific advantages:

Offers high strength and hardness, making it suitable for structural applications.

Can be easily formed and molded, ideal for manufacturing complex shapes.

Used in automotive, aerospace, and construction sectors.

304 grade is one of the most widely used:

Known for its versatility and ability to perform well in a wide range of applications.

Offers good resistance to oxidation and corrosion in most environments.

Popular in kitchen appliances, architectural panels, and general fabrication.

| Grade | Corrosion Resistance | Strength | Formability | Common Applications |

|---|---|---|---|---|

| 316 | High | Medium | Medium | Marine, Pharma |

| 301 | Medium | High | High | Automotive, Aero |

| 304 | Medium | Medium | High | Kitchen, Fabrication |

The selection between 316, 301, and 304 stainless steel foil sheet depends on specific needs such as corrosion resistance, strength, and formability.

Adherence to quality standards ensures that the selected grade meets the required specifications.

All three grades contribute to sustainability, with recyclability being a common feature.

Understanding the differences between 316, 301, and 304 stainless steel foil sheets is essential for making informed decisions tailored to specific applications. Whether it’s the robustness of 301 or the corrosion resistance of 316, the right choice can lead to optimal performance and satisfaction.

Proper maintenance and care of stainless steel foil sheet are essential to preserve its appearance, functionality, and longevity. Here’s a comprehensive guide.

Regular cleaning maintains the aesthetic and integrity of the material:

316 stainless steel foil sheet offers corrosion resistance, but general practices include:

For stainless steel foil used in cooking:

For stainless steel foil in heat treating:

Adhering to manufacturer guidelines ensures compliance with quality standards.

Regular professional inspection and maintenance can detect issues early and ensure optimal performance, especially for critical industrial applications.

Proper maintenance and care of stainless steel foil sheet, whether it’s 304 or 316 stainless steel foil sheet, are vital for preserving its qualities and extending its lifespan. By following these guidelines, users can enjoy the benefits of this versatile material for years to come.

Purchasing high-quality stainless steel foil sheets requires careful consideration of several factors. Here’s a guide to making the right choice.

Understanding specific needs, such as grade (e.g., 304 or 316 stainless steel foil sheet), thickness, and application, helps narrow down options.

Various suppliers offer stainless steel foil sheets, including:

Directly purchasing from manufacturers may offer competitive pricing and customization.

Distributors often provide a wide selection and added services like delivery.

E-commerce platforms offer convenience and a variety of options.

Look for suppliers adhering to quality standards like ISO 9001 and offering products with precise chemical composition and thickness tolerance.

Choose suppliers committed to environmental sustainability and offering recyclable products.

Compare prices, but consider the total value, including quality, service, and delivery.

Check customer reviews and ask for references to gauge the supplier’s reputation.

Many suppliers offer samples and free tests, such as chemical composition analysis.

Consider lead times and delivery options to match timelines and logistics requirements.

Some suppliers offer customization, such as specific thickness or surface finishes.

Evaluate the after-sales support, including warranties and customer service.

Purchasing stainless steel foil sheets, whether it’s for cooking or heat treating applications, requires careful consideration of factors ranging from quality and compliance to cost and support. By following this guide, buyers can find the right supplier to meet their specific needs and ensure a successful purchase.

Read more about the: 0.01~0.05mm Stainless Steel Foil Exhaustive Guide

Understanding the differences between carbon steel foil, mild steel foil, and stainless steel foil sheet helps in selecting the right material for specific applications. Here's a comparison.

Characteristics of carbon steel foil include:

Contains mainly iron and carbon, with higher carbon content than mild steel.

Generally stronger and harder than mild and stainless steel.

Less resistant to corrosion compared to stainless steel.

Suitable for tools, machinery parts, and high-strength components.

Mild steel foil's properties include:

Composed of iron and a lower carbon content compared to carbon steel.

Offers moderate strength, less than carbon steel but more than most stainless steel grades.

Susceptible to corrosion, requiring protective coatings.

Used in automotive, construction, and general fabrication.

Distinct properties of stainless steel foil sheet:

Contains iron, chromium, nickel, and other elements, providing corrosion resistance.

Various grades like 304 and 316 stainless steel foil sheet offer different properties.

Highly resistant to corrosion, especially certain grades like 316.

Versatile in applications, including cooking, heat treating, and decorative purposes.

| Material | Strength | Corrosion Resistance | Applications |

|---|---|---|---|

| Carbon Steel Foil | High | Low | Tools, Machinery |

| Mild Steel Foil | Medium | Low | Automotive, Construction |

| Stainless Steel Foil Sheet | Medium | High | Cooking, Heat Treating |

Carbon steel foil, mild steel foil, and stainless steel foil sheet each offer unique advantages and limitations. While carbon steel provides strength, stainless steel offers corrosion resistance, and mild steel balances strength and cost. Understanding these differences enables the selection of the right material for specific needs and applications.

Stainless steel foil sheet must comply with various industry standards and certifications to ensure quality, safety, and performance. Here's an overview.

ISO 9001 sets requirements for quality management systems, ensuring consistent quality and continuous improvement.

Involves defining processes, procedures, and responsibilities.

Enhances customer satisfaction and ensures product quality.

ASTM provides standards for materials, including stainless steel foil sheet, defining mechanical properties, chemical composition, and testing methods.

European standards (EN) may apply to stainless steel foil sheet, depending on the region and application.

For stainless steel foil used in pressure vessels, ASME standards define design and fabrication requirements.

For stainless steel foil in cooking:

Ensures that the material is safe for food contact.

Certifies that the product meets public health and safety standards.

Stainless steel foil sheet may need to comply with environmental regulations, such as REACH in Europe.

Specific standards apply to different grades, such as 304 or 316 stainless steel foil sheet.

Select suppliers who adhere to these standards and conduct regular audits to verify compliance.

Certain industries or applications may have custom standards, such as aerospace or medical devices.

Compliance with industry standards and certifications, including ISO 9001, is essential for ensuring the quality, safety, and performance of stainless steel foil sheet. These standards provide a framework for manufacturing, testing, and utilizing the material, giving both manufacturers and consumers confidence in the product's reliability.

The magnetic properties of steel foil, including stainless steel foil sheet, can significantly impact various applications. This article explores these effects.

Different steel types exhibit varying degrees of magnetism:

These are generally magnetic due to their iron content.

Some stainless steel grades, like the 400 series, are magnetic.

Grades like 304 and 316 stainless steel foil sheet are typically non-magnetic.

Magnetic properties are essential in shielding, connectors, and inductors.

Non-magnetic stainless steel is preferred in MRI machines to prevent interference.

Magnetic properties can affect sensors and electronic components in vehicles.

Magnetic stainless steel can be used for decorative features or functional components.

For stainless steel foil used in heat treating, magnetism can affect thermal conductivity and other material properties.

Stainless steel's magnetic properties may influence its compatibility with induction cooktops.

Choosing the appropriate grade, such as magnetic 430 or non-magnetic 316 stainless steel foil sheet, depends on the specific application.

Ensuring the desired magnetic properties requires careful quality control and testing, including using spectrometers to analyze chemical composition.

Magnetic properties can also influence recycling and sorting processes.

Understanding the magnetic properties of steel foil, including stainless steel foil sheet, is crucial for selecting the right material for specific applications. Whether it's the sensitivity required in medical devices or the functionality needed in electronics, these properties play a vital role in determining the material's suitability and performance.

When transporting 304 stainless steel foil, proper packaging is crucial to protect the delicate material from damage, moisture, and external

The invention of stainless steel, often hailed as one of the most significant breakthroughs in metallurgy, was attributed to Harry