ssThe material choice is not just a technical decision—it is a safety commitment. From food processing lines to commercial kitchens and pharmaceutical packaging, manufacturers must rely on metals that remain stable, hygienic, and compliant under demanding conditions. This is where 304 Stainless Steel Foil for food-grade applications continues to stand out as one of the most trusted materials worldwide.

Among all stainless steel grades, 304 stainless steel foil has earned its reputation for food contact use because of its excellent corrosion resistance, non-reactive surface, and ease of fabrication. Whether used in food wrapping systems, heat exchangers, conveyor belts, or industrial food equipment, it delivers a rare balance of performance, durability, and regulatory compliance.

This in-depth guide explores why 304 Stainless Steel Foil for Foods applications dominates the global market, how it compares with other grades, and what manufacturers should consider when selecting it for food-grade environments.

Stainless Steel and Food Safety Standards

Stainless steel is an iron-based alloy containing chromium, which forms a passive oxide layer that protects the metal from corrosion. According to Wikipedia’s stainless steel overview, this chromium-rich surface is what makes stainless steel hygienic and resistant to oxidation.

In food-related environments, materials must meet strict criteria. They must not contaminate food, react with acidic ingredients, or degrade under temperature changes. 304 Stainless Steel Foil for Food applications satisfies these demands consistently, which explains its widespread acceptance in food safety regulations across Europe, North America, and Asia.

Unlike coated metals or plastics, stainless steel does not leach chemicals into food. Its smooth surface prevents bacterial adhesion, making cleaning faster and more effective. These characteristics make stainless steel foils especially suitable for food contact surfaces.

To understand the broader scope of stainless steel foils, the detailed explanation on what stainless steel foils are provides valuable background.

What Makes 304 Stainless Steel Foil Food Grade?

Chemical Composition and Stability

304 stainless steel belongs to the austenitic family. It typically contains around 18% chromium and 8% nickel, a composition that provides exceptional corrosion resistance and structural stability. This balance is crucial for 304 Stainless Steel Foil for Food use, as it ensures the material does not degrade when exposed to moisture, salt, or acidic food substances.

Unlike carbon steel or low-grade alloys, 304 stainless steel foil maintains its integrity even after repeated cleaning cycles. This is especially important in food factories where equipment undergoes daily washdowns.

Non-Reactive Surface for Food Contact

Food-grade materials must remain chemically inert. 304 stainless steel foil does not react with dairy products, oils, spices, or acidic foods like citrus and tomatoes. This neutrality preserves taste and prevents metallic contamination.

Because of this property, 304 Stainless-Steel Foil for Food applications are common in commercial kitchens, food packaging machinery, and beverage processing systems.

Key Properties of 304 Stainless Steel Foil for Food Applications

Corrosion Resistance in Food Environments

Food processing often involves moisture, salt, and fluctuating temperatures. 304 stainless steel foil resists rust and oxidation in these environments better than most alternatives. While chloride-rich conditions may require higher grades, 304 performs exceptionally well in standard food settings.

Temperature Tolerance and Heat Resistance

304 stainless steel foil handles both high and low temperatures without losing mechanical strength. It performs reliably in ovens, freezers, and thermal processing units. This versatility makes 304 Stainless Steel-Foil for Food suitable for baking trays, heat shields, and thermal barriers.

Cleanability and Hygiene

Smooth surface finish is a major advantage. Bacteria struggle to adhere to stainless steel, especially when polished. This hygienic quality supports food safety compliance and reduces contamination risks.

For a broader look at where stainless steel foils are used, the article on use of stainless steel foils offers useful industry examples.

304 vs Other Stainless Steel Grades in Food Applications

304 vs 316 Stainless Steel Foil

While 304 is widely used, some applications require enhanced corrosion resistance. 316 stainless steel foil, which includes molybdenum, performs better in chloride-heavy environments such as seafood processing.

However, for most standard food-grade uses, 304 Stainless Steel Foil for Food offers a cost-effective and reliable solution. You can explore this comparison further in the detailed guide on what is 316 stainless steel foil.

304 vs 430 Stainless Steel Foil

430 stainless steel lacks nickel, which reduces corrosion resistance. While it is cheaper, it does not match the performance of 304 in food environments. For long-term hygiene and durability, 304 remains the safer choice.

A deeper discussion on material selection can be found in which stainless steel is food grade.

Food Industry Applications of 304 Stainless Steel Foil

Food Processing Equipment

In processing plants, stainless steel foil is used for linings, protective layers, and insulation barriers. 304 Stainless Steel Foil for Food ensures equipment remains compliant with hygiene standards while resisting wear.

Commercial Kitchen Surfaces

Professional kitchens rely on stainless steel for worktops, splashbacks, and heat shields. Thin foils offer flexibility while maintaining strength and cleanliness.

Food Packaging and Wrapping Systems

Although stainless steel foil is not used like aluminum for consumer wrapping, it plays a critical role in industrial packaging machinery. It provides structural reinforcement and thermal protection during sealing and sterilization processes.

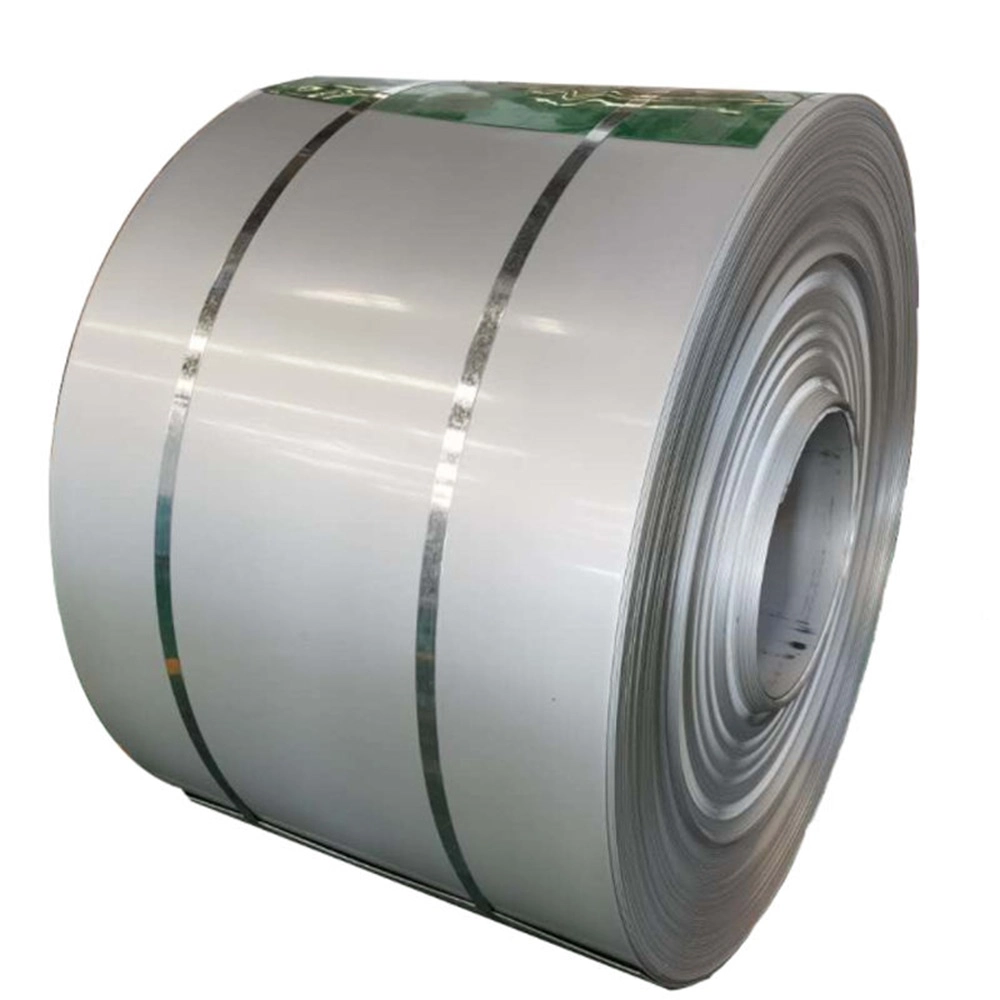

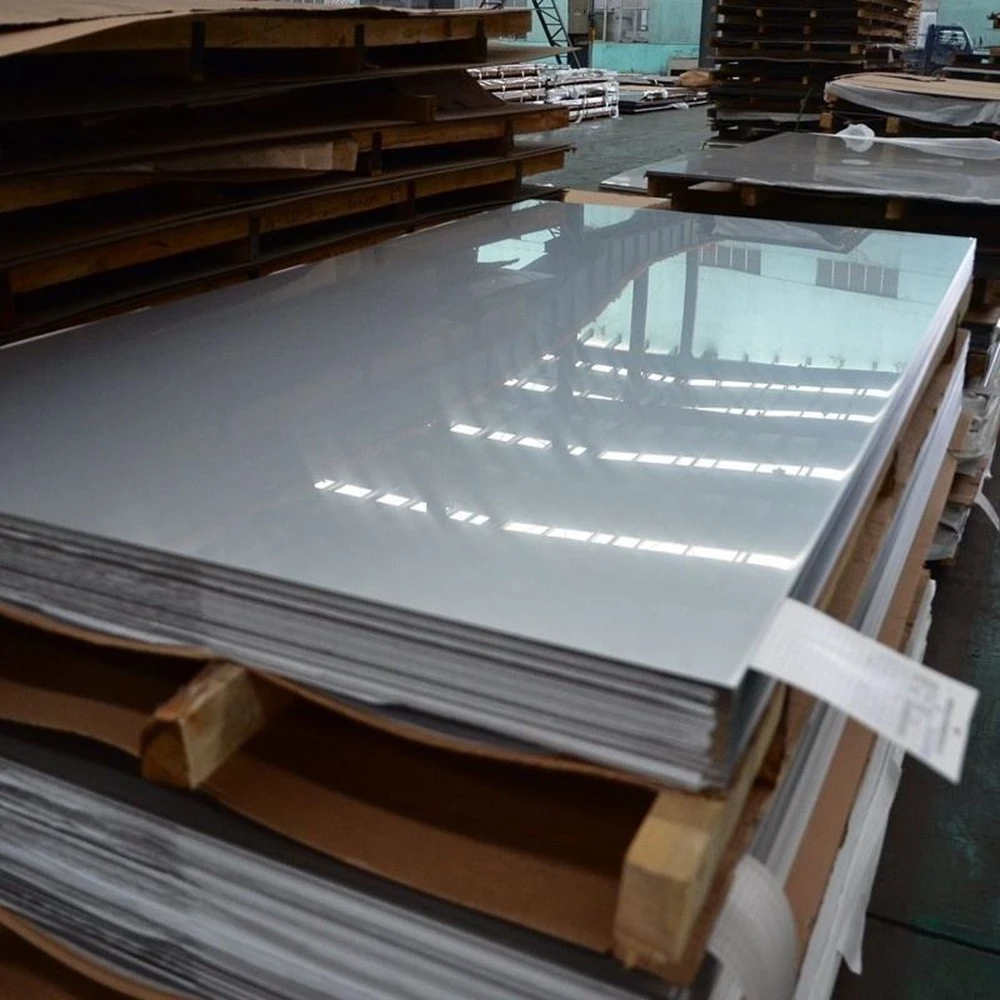

Manufacturing and Thickness Options

304 stainless steel foil is available in a wide range of thicknesses, often starting from ultra-thin gauges for precision applications. Thinner foils allow flexibility and weight reduction without sacrificing performance.

Manufacturers sourcing 304 Stainless Steel Foil for food often select finishes such as bright annealed or matte, depending on hygiene and aesthetic requirements. Product availability and specifications can be explored directly through stainless steel foil products.

Regulatory Compliance and Certifications

Food-grade stainless steel must comply with international standards such as FDA, EU food contact regulations, and ISO guidelines. 304 stainless steel foil meets these requirements when produced under controlled manufacturing conditions.

Compliance ensures that 304 Stainless Steel Foil for Food applications are safe for direct and indirect food contact. This makes it a preferred material for export-oriented food manufacturers.

Sustainability and Environmental Benefits

Sustainability matters in today’s manufacturing landscape. Stainless steel is 100% recyclable and retains its properties after recycling. Choosing 304 Stainless Steel Foil for Food supports circular economy principles and reduces environmental impact.

Compared to disposable or coated materials, stainless steel offers long service life and minimal waste. This durability aligns with sustainability goals in the food and beverage sector.

Why Manufacturers Trust StainlessSteelFoil.com

When sourcing high-quality stainless steel foil, consistency and expertise matter. Stainless Steel Foil provides reliable information, technical guidance, and product options tailored to food-grade applications.

Their educational resources, including insights shared on the blog section, help manufacturers make informed decisions. For customized requirements or technical support, reaching out via the contact page ensures direct assistance.

Future Trends in Food-Grade Stainless Steel Foils

The food industry continues to evolve with automation and hygiene-focused design. Demand for thinner, stronger, and more precise stainless steel foils is increasing. 304 Stainless Steel_Foil for Foods applications will remain central to this evolution due to its adaptability and proven performance.

Advancements in surface finishing and precision rolling will further enhance its usability in advanced food processing systems.

Summary

Choosing the right material is essential for food safety, durability, and compliance. 304 Stainless Steel Foil for foods applications continues to set the industry standard due to their corrosion resistance, hygiene, and versatility. From processing equipment to commercial kitchens, this material delivers consistent performance while meeting global food-grade regulations. For manufacturers seeking reliability and long-term value, 304 stainless steel foil remains a smart and proven choice visit Stainless Steel Foil and contact us.

FAQs

Is 304 stainless steel foil safe for direct food contact?

Yes, 304 Stainless Steel Foil for Food is widely approved for direct food contact due to its non-reactive surface and compliance with food safety standards.

Can 304 stainless steel foil handle acidic foods?

304 stainless steel foil resists most foods acids effectively, making 304 Stainless Steel Foil for Foods suitable for sauces, fruits, and dairy products.

How does 304 stainless steel foils compare to aluminum foil?

Unlike aluminum, 304 Stainless Steel_Foil for Foods does not react with acidic ingredients and offers superior durability in industrial applications.

Is 304 stainless steel foil recyclable?

Yes, 304 Stainless Steel Foils for Food is fully recyclable and support sustainable manufacturing practices.

What thickness is best for food applications?

The ideal thickness depends on use, but 304 Stainless Steel_Foil for Food is available in ultra-thin to heavier gauges for diverse needs.