As a ss coil manufacturer, if you need an excellent stainless steel coil supplier to help you stabilize the stainless steel raw material supply chain, Yaoyi may be the answer for you. With more than 25 years experience of production, we are able to provide with a very competitive price of stainless steel coils.

If you need to purchase stainless steel coil with a thickness of 0.02~ 2mm, we can give you the right solutions. Our excellent production and R&D capabilities can help you to meet the requirements. Meanwhile, you are allowed to get the free samples before purchasing, it will help you to confirm the quality of the product.

Myriad provides professional stainless steel coil services, such as high-quality raw materials, mechanical solutions, suggestions for good alternative products, and complete experimental data reports. Get a quick quote now and reduce the cost of stainless steel coils.

Myriad strictly abides by the ISO:9001:2015 management system and provides you with the best quality stainless steel coils.

China is the world’s largest producer of stainless steel coils. Every year, China exports ss coils to markets around the world. Stainless steel coil include cold-rolled ss coils and hot-rolled ss coils. Today, I want to show you how to successfully source ss coils from China. I will take you through all the basic knowledge you must know-how to buy, transport, packaging, etc..Let’s look directly at the main topics of this guide:

Stainless Steel that is resistant to low corrosive media, including air, vapor, water, or stainless steel, is known to be under ss coil. The hardness of the stainless steel is normally higher than that of the aluminum alloy and the cost is higher.

Stainless Steel Coil products are also available for a wide range of alloyed materials, including but not limited to 300, 400, and PH alloys. There is a thin 0019′′ spiral available and a broad range of applications up to 065′′ are always in support. There’s a small slit-width belt and a specialist for custom bobbins. Experts have a 0.024′′ narrow belt and a 0.040′′ narrow spiral edge.

In many industries, ss coil is widely in use. The stainless spiral can be in production with or oscillated to suit the needs of customers. Like heat exchangers, heating systems, soft piping, filtration devices, cutlery, springs, and operating instruments are typical uses of ss coil slit bob.

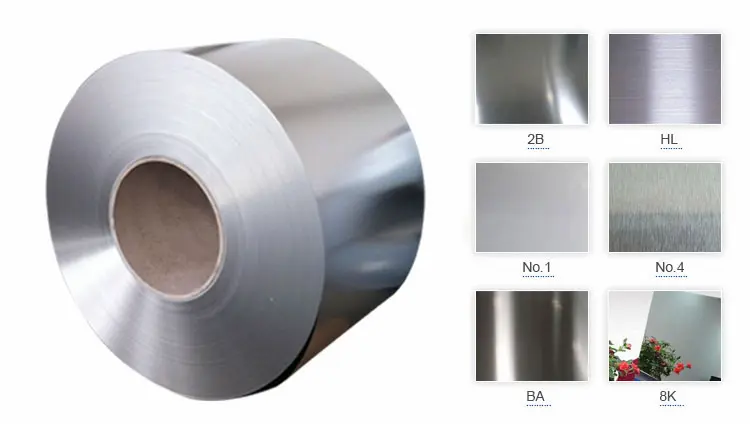

The look and feel of the stainless steel coil is different according to different requirements.

Thus, the multi-layer steel bowl is together into a whole that enhances heat exchange and heating exchange and significantly increases performance.

Gradually, damp resistance at high temperatures, resistance to impact corrosion, resistance to ammonia; anti-scaling, stain-free, anti-oxidation and corrosion; Long service life, time reduction, cost reduction; Good tube installation, direct tube substitution, clean and reliable; Uniform pipe wall, the wall thickness of just 50-70% of copper pipe, the total heat conductivity of hot tube better than the copper tube; this is the perfect heat exchange for the processing of old and new units.

Gradually, the uses for the exchange of heat between the interior and the outside of the steel coil such as steam heat, condensing tubes, etc.

Industrial ss coil, extra-long coils, U-shaped tubing, vacuum tubing, flow tubes, flow tubes, and spiral buckets. The material of the coils in the manufacturing state and selection according to customer demands.

Keep reading: A Complete Guide to Steel Coil Suppliers

Consequently, 2B is a reflective gray shine with a smooth finish. Surface finish is most commonly used.

Cold rolled, annealed to maintain a strongly reflecting finish in a controlled environment.

Scaled finish, perfect when the finish of the surface is not a major issue.

The highest quality product is in display in the framework of the valid management system of ISO 9001:2015 and the production is in display to BS EN 10088-2 specification.

Hence, ss coil is a steel type that doesn’t or doesn’t rust at high pressure. A corrosion-resistant alloy consisting of composition elements such as iron, chromium, nickel, and other metals in several instances. SS includes several fundamental elements, which are in combination with a strong alloy.

For instance, these bobbins show different features, such as good welding properties, higher corrosion resistance, stability, and greater strength. They are commonly in use in the marine industry, filtration industry, pharmacy, turbine, and energy generation.

Always Provides You with the BEST Austenitic Stainless Steel Products

Stainless steel is iron, chrome, and sometimes nickel and other metals alloy resistant to corrosion. Coiled tubes of Stainless Steel are in the composition of chromium, nickel, carbon, silicon molybdenum, phosphorous, and sulfur.

Conversely, the application of ss coil belt in various food and beverage industries, equipment, gas and oil, funnel, petrochemical, CNG, instrumentation, heat exchanges, heating hardware, thermal and nuclear power plants, and in pipelines, electrical engineering.

Meanwhile, high corrosion resistance is the benefit of ss coil, which can be in use in all sizes, have low construction costs, increase the health of the frame, and minimize the use of equipment and breaks.

Although the plates are a form of stainless steel in the series 300, 400, and 200, each version has its characteristics. The 304’s most common grades can easily collpase or cast and is one of the most popular grades because of its excellent corrosion resistance and sales capability.

Provided that 316 is a molybdenum alloy that improves corrosion resilience and is particularly effective in acidic conditions as it offers greater corrosion resistance by pitting. 321 is a Titanium-Made 304 version, is corrosion-resistant and very sudden. Type 430 is a ferritic spiral alloy that offers high corrosion resistance and is mainly in use in the home and food industries.

Read on: A Complete Guide to 201 Stainless Steel

ASTM-A-666/UNS S20100 developed originally as the result of World War II resource allocation, includes lower nickel content (4.5% vs 8.1%) and higher Manganese content than 301 and 304. The T201 addresses persistent nickel price fluctuation and has now turned into a viable choice for lower costs of these austenite grades with comparable corrosion resistance and formability to T301 or T304.

301 ASTM-A-666 is slightly smaller in chromium and nickel content than the stainless strip Form 302. Type 301 works harder and maintains a higher ductility than Type 302, due to its reduced nickel content. 301 Stainless Strip stocks in ranges 0.0022′′ to 0.050′′ precision split in widths 0.022 to 12′′. Form 301 is available in a variety of temperatures.

The ASTM A-666 is the high yield or Extra Full Rough for special use requiring extra strongness and hardness. For this additional high-strength material, a minimum tensile strength of 270000 PSI is available. 301 high yield gage belt from 0.002′′ to 0.032′′ accurate gage to 0.022′′. Gibbs has a high yardstick of 301. AMS5519 – Only high yields of type 301 for chemical products and chemical properties.

ASTM A-666, the general-purpose stainless alloy is 18% chromium and 8% nickel Stylish steel Strip Coil & Coil 302 Stainless Steel Strip. It is very heat and corrosion-resistant. The heat treatment of type 302 can’t be decided and after cold working is mildly magnetic. It quickly welds. Stainless Gibbs stock in sizes between.003 and.030 precision slit to widths between.022′′ and 12′′ in gauges.

Keep on reading:301 Stainless Steel Foil: Production, Application, and Packaging

ASTM A-666 is the same as Type 302 but contains 0.08% of the full carbon content. The 304 strip coil and the slotted coil 304 are very similar in stainless steel and width. This material blends outstanding corrosion resistance with formability. Type 304 Gibb holds 0,0019′′ to 0,062′′ stainless stocks, and 0,0019′′ to 0,025′′ in gauges of T304.

DDQ Stainless Steel Strip 305 is in use for applications requiring poor work hardness and normally extreme cold forming during production. The higher nickel content reduces the hardness of the work and makes it ideal for applications with a deep drawing. Gibbs supplies the consistency of type 305 Eyelet in 0.005′′ – 0.025 ′′ sizes in a deeply torn condition.

316 ASTM A-666 is ss coil-carrying molybdenum in stainless steel with a considerably improved chemical resistance in comparison to the basic sample of chrome-nickel. Type 316 is also slower, stress-to-breaker, and more tensile than any other stainless steel at temperatures. Gibbs stocks the content in 0,005′′ –0,025′′ gauges under the rinsed and 1/4 harsh conditions.

Read my article on The reason why we can produce the perfect 301 Stainless Steel Strips?

316Ti is stabilized by the stainless type 316 titanium version. It was designed with the ASTM A240 and DIN/EN 1.4571. In case of higher temperatures between 900°F and 1500°C (425°C and 815°C), titanium is added to minimize corrosion. The alloy prevents corrosion at a higher temperature as the addition of titanium stabilizes the structure against chromium precipitation. This alloy is engineered to increase the high-temperature performance of 316 and 316L. There is the widespread use of flexible pipes and fireplaces.

Condition C, usually 17-7 pH, has the corrosion resistance of type 302 and greater resistance to heat and strength. If the “CH” tensile has formed, a maximum of 900°F for an hour can be processed. In the “C” cold rolling conditions Gibbs invents a coil with gauges ranging from 0,0008 to 0,025′′ in 17 chrome-7 nickel ss.

420 is the martensitic coil of 12 percent chromium. 420 is magnetic and can be hardened in all environments under heat treatment. It is mostly used for cupboards, medical appliances, scissors, and knives. It is highly corrosion resistant and is mostly ground and polished.

In order, electricity, textiles, rubber, food, medical equipment, aviation, aerospace, communications, petroleum, and other industrial fields are widely in application in stainless steel coils.

Also, industrial stainless steel coil, such as heat exchange, heat exchanger, gasoline, chemical, pesticide, medicinal, nuclear, etc.

Moreover, fluid coils for stainless steel, such as drinks, milk, beer, drinking water, medical devices, etc.

Besides, mechanical structural stainless steel coil is printing, dyeing, printing, sewing equipment, medical equipment, kitchen appliances, car and ship accessories, design, decoration, and construction, etc.

Additionally, a bright coil made from stainless steel welded with steel strips reduced wall thickness from thick to thin. This method allows the wall thickness to be consistent and smooth and a weld-free effect forms the reduced wall extended tube wall. It is a seamless pipe according to the naked eye, but the operation is a welded pipeline.

The process of reducing the wall is followed by bright glazing to prevent oxide from forming the inner and outer walls, and the interior and exterior walls are luminous and exquisite, as are required for medical items. To assess the outer diameter, external tolerance will usually be greater or less than 0,01mm in size, that is, the large and small drawing process involves sizing.

Try for free 304 Stainless Steel Pipe: Classification, Types and Applications

It is obvious that when looking for a suitable supplier of stainless steel coils, a certain understanding of the process is necessary.When you find a stainless steel coil supplier, you should be careful.

In fact, before you ship, you hardly have to worry about the possibility of an unlikely event happening.Stainless steel buyers who understand this process make this process very easy. They know all the steps that must be followed in practice and the corresponding related documents. Of course, knowledge and experience go hand in hand.

Therefore, an experienced stainless steel supplier would be the ideal choice, because even in the most difficult situations, they know how to maneuver. Please select a suitable stainless steel supplier according to the status of the stainless steel order you need to purchase.In the end, you will find that the process is simple, safe, and comfortable.

Read more about 304 Stainless Steel Sheet: Technicalities, Features and Applications

In fact, the prices of traders and manufacturers are not the same.

Traders and manufacturers have very different empirical methods. For traders, they usually do inventory and keep a certain amount of hot-selling stainless steel coils. For example 0.1 thickness 304 cold-rolled stainless steel coil, etc. They will predict market price trends and stock up in advance. So they will accept LOW MOQ. And the response is quick. But their prices are generally higher. Moreover, traders of different grades have different products and some stocks. Some small dealers are unable to make inventory due to financial pressure, so they also ask other dealers to purchase steel, which leads to their high prices and no quality assurance.

Learn more about 316 Stianless Steel

Usually, the output of each size of stainless steel produced by the stainless steel coil production plant is 7 tons. This will cause them to have higher requirements for the minimum order quantity. Because if you want a small amount, it means that the manufacturer needs to make inventory for you, which will cause their inventory backlog and capital pressure. For example, you need to purchase 1 ton of 304 stainless steel, HV: 350, thickness 0.15mm, width 60mm. Then the stainless steel production plant will produce 7 tons of stainless steel of this specification for you according to this size.

Of course, the width depends on the size of the existing rolling mill in the manufacturer. If they are a four-high rolling mill, they can only make ss coils with a width of 600mm at most. Closer to home, then the manufacturer will make 6 tons of inventory for you. If you do not place subsequent orders, the manufacturer will have to keep 6 tons of inventory until the next buyer with the same demand as you appear. This will bring great financial pressure to the manufacturer. So usually, stainless steel factories have high requirements for MOQ. But their prices are cheap because there is no middleman.

Get it now:AISI 302 Stainless Steel

Advantages of distributors:

1.LOW MOQ

2. Flexible operation

3. Many types of products

Disadvantages of distributors:

1. High price

2. Quality cannot be guaranteed

3. Not professional enough

Advantages of the manufacturer:

1. Low price

2. High-quality factories trace their raw materials into steel plants to ensure quality

3. Strong professionalism

4. High reliability

Disadvantages of the manufacturer:

1.High MOQ

2. Small factories have a single product category

Now, this is the core element of any substantive business. By the way, there is no shortcut. This is a prerequisite for the establishment of any business relationship.You must first understand what is the stainless steel you want to purchase?wd

You can use “Sinosure” to reduce the company’s reputation, or use “qichacha” to confirm the company’s current reputation and transaction risks. If you only have the English name of this company, you can search for it based on the English name given by Google and translated into Chinese. If you find that the trader’s reputation is not good or is facing judicial prosecution, please give up the trader. For professional issues, you can feel the professional level of your opponent through direct communication with stainless steel coils. Do not place an order in a hurry, be sure to confirm the product link before confirming the order. The more questions asked, the easier it is for the other party to make mistakes. In the same way, you can also go to a stainless steel production manufacturer to check its establishment time, or you can ask them about their raw material procurement channels and ask them to issue a procurement certificate.

Whether the purchase certificate can be issued is very important to the integrity of this manufacturer. Even if the other party only gives you a Chinese certificate, you can ask a friend who understands Chinese or use Google Translate to check whether the other party’s information is accurate.A reliable stainless steel coil supplier can ensure that all production processes are carried out smoothly and efficiently when necessary. It can also ensure the quality of ss coils.

Try for free information about the A Complete Guide to AISI 321 Stainless Steel

It means that the stainless steel coil needs to be produced within the set time. Stainless steel coils need to be delivered within the set quality range. The quality of ss coils can be maintained for a long time.Of course, you know the consequences of failing to meet the above conditions, and you will encounter losses you never thought of. Therefore, the easiest way to prevent this is to find a reliable stainless steel supplier.

Let me tell you the truth here.

Becoming a stainless steel supplier is a systematic project. Therefore, whether it is a trader or a manufacturer, they all need a stable supply chain system.

For the trader, they need to establish a strong relationship with each manufacturer or other trader to ensure that they can pick up the goods at any time, even in the peak season.

For manufacturers, they need to establish strong connections with various steel companies, and they also need to establish strong connections with some hot-rolled distributors to ensure their raw material procurement.

Let us clarify. Any stainless steel supplier who lacks a comprehensive ss coil tracking method, whether in production or in transportation, is not worth your time.

In fact, in this technologically advanced era, you should tell any stainless steel suppliers not to worry, because everything will be fine. Any serious stainless steel supplier knows to track the status of the ss coils you need to purchase at each stage until they receive the essence of the goods.

In this regard, you can also track ss coils from beginning to end, even if you have problems after use, they will keep samples for you to further discover and track.

This is the type of ss coil supplier you need now.

Finally, when you are looking for a suitable stainless steel coil supplier, in many cases, their attitude towards various issues is also very important. In this case, what I mean is that the ideal company should provide excellent customer service. The overall approach to how they handle your complaints, concerns, needs, suggestions and inquiries should be used as a benchmark. In other words, what I want to say here is that the ideal ss coil supplier should be responsive and flexible.

Similarly, the company should be able to establish and strengthen supply chain partnerships with you outside of ordinary business. Now, all these are the key elements you need to research in order to find a good ss coil supplier from China. Remember, purchasing ss coils is not an easy task. Therefore, ss coil suppliers must demonstrate outstanding knowledge, experience, reliability and commitment. Now, let us shift the focus to what you need to prepare in advance for purchasing stainless steel coils.

Provide you with the best quality stainless steel of 200 series and 300 series

The manufacturer and the trader have different perspectives when purchasing stainless steel coils.

You need to consider what kind of stainless steel coil is suitable for you, and whether there is an alternative stainless steel coil that can bring you higher economic efficiency.

First of all, you need to talk to your engineer or production person in charge to understand the range, specifications, varieties, and packaging of the physical properties of the ss coils they need to purchase. Also understand the applications of stainless steel coils.

The Second, you need to confirm with them the procurement cycle or urgency. This content will seriously affect the approach you take in the next purchase.

Third, confirm the trade terms you can accept, such as FOB, CIF, CFR…

Fourth, confirm your target price (this is not necessary), this can help you close the transaction faster.

At last, make sure that you have at least two stainless steel suppliers on the same type of stainless steel coil. This can reduce the risk.

You need to integrate your customer needs first. Understand what kind of stainless steel coil customers need to purchase. You can use the methods mentioned above to determine the customer’s purchasing needs. At the same time, you can also predict in advance the customer’s next purchase requirements. In order to expand your business, you can talk to stainless steel suppliers to understand their current application range of ss coils and what are the best-selling products, so as to infer whether this ss coil is suitable for your market. This can further expand your business landscape.

So how to determine the approximate purchase price of ss coils?

You can follow the news “here”, and they will report the latest Chinese stainless steel market base price every day. Usually the price of cold rolled stainless steel coil = hot rolled stainless steel coil + 462usd/ton (processing fee).

So how to determine the approximate purchase price of stainless steel coils?

You can follow the news “here”, and they will report the latest Chinese stainless steel market base price every day. Usually the price of cold rolled stainless steel coil = hot rolled stainless steel coil + 462usd/ton (processing fee).

Get it now:A complete guide to AISI 410 Stainless Steel

We mainly introduce the surface of stainless steel coils for industrial use.

The most important ones on the market are NO.1, NO.2D, 2B, BA, HL.

|

Name |

Processing type |

Surface Condition |

Remarks |

|

No.1 |

Hot rolling, heat treatment, pickling |

No scale |

The method of mechanical descaling (coarse grinding or shot peening), the surface roughness is 0.3~0.6μm. |

|

NO.2D |

Cold rolling, heat treatment, pickling or descaling |

The surface is uniform and matt |

Heat treatment and pickling after cold rolling. The matt surface is produced by pickling or descaling. It can be smoothed with a rough roller. The rough surface processing facilitates the retention of lubricant on the surface of the steel plate during deep drawing. This kind of surface is suitable for processing deep-drawn parts, but these parts need to be polished after forming, and the surface roughness is 0.3~0.6μm. |

|

2B |

Cold rolling, heat treatment, pickling or descaling, bright processing |

Smoother and straighter than 2D surface |

On the basis of the 2D surface, the steel plate after heat treatment and descaling is smoothed with a small reduction amount with a polishing roller. It is the most commonly used surface processing. Except for extremely complex deep drawing, it can be used for any purpose. The surface roughness is 0.10~0.25μm. |

|

BA |

Cold rolled, bright annealing |

Smooth, shiny, reflective |

After cold rolling, bright annealing is performed in a controlled atmosphere furnace. Generally, dry hydrogen or a mixed atmosphere of dry hydrogen and dry nitrogen is used to prevent oxidation during annealing. It is also a commonly used surface processing for subsequent processing. |

|

HL |

Cold rolling, pickling, leveling, grinding |

Continuously rubbed |

Polish the surface with an abrasive material of appropriate size to make the surface continuous. |

Try for free AISI 4140 Low Alloy Steel

The purchase of stainless steel coils from China will be guided by specific policies. Moreover, since the procurement of stainless steel coils from China is more or less an international affair, it means that it formulates its policies from the International Chamber of Commerce. So, what do the general rules of international trade terms mean?

For those who don’t know, it refers to a set of rules and regulations that outline the merchant’s responsibilities in terms of delivery.

The general rules of international trade terms are usually different from a commercial transaction, contract, and mode of transportation.

When purchasing stainless steel coils from China, you need to follow some important considerations in international trade terms; After importing goods from China, you are expected to pay all necessary and applicable taxes.

You must be clear about who pays the duties and when to pay. What happens is that buyers will always want to know the actual price including all shipping and taxes.

Once you choose your ideal transportation company, it will always act as a freight forwarder. Therefore, the company will assist you in the various simplification of the consignment process. Nevertheless, let us also look at some common international trade terms that we need to know when purchasing stainless steel coils from China.

This happens when the cargo is safely loaded onto a ship at an agreed specific shipping port. Therefore, these are important trade terms for you to purchase stainless steel coils from China, and you need to understand these terms. It is also important to understand that the trade terminology of transportation always changes from time to time. For this reason, you need to be aware of any updates and always keep them up to date.

Read on:AISI 430 Stainless Steel

Refers to cost, insurance, and freight. Essentially, this means that suppliers can only deliver goods after they are properly packaged, cleared for customs, and safely stored onboard for transportation.

Paid transportation and insurance fees mean that the seller delivers the goods to the carrier or any other authorized party at the agreed place.

Cost and freight mean that the seller is solely responsible for prepayment of the contract related to freight.

Freight paid to means that the seller delivers the goods to a specific carrier or designated person at a place mutually agreed between the buyer and the seller.

Delivery to the terminal means that the seller starts the delivery the moment the goods are unloaded from the target terminal.

Delivery in Place is a term that means that the seller delivers the goods at the moment they arrive at the intended destination and wait for unloading.

Delivery Duty Paid is a term that means that the seller has delivered the goods, and these goods are cleared at customs and ready for unloading. Delivery should also be at the agreed destination or specific location.

Also known as EX works, which means that the seller has delivered the properly packaged items to the buyer at the agreed place.

Free Side-side Ship means that the seller delivers the goods, properly packaged and cleared customs for export. This also includes placing them next to ships at agreed destinations.

Free carrier means that the seller has completed the handling of the goods, corresponding packaging, and delivery obligations when exporting customs clearance.

Free on board-is a term that instructs the seller to deliver goods that have been packaged and cleared for export.

Keep reading: A Complete Guide to Stainless Steel AISI 4140

There are two packaging methods, one is wide stainless steel coils, the other is a narrow stainless steel coil.

It refer to cold-rolled stainless steel coils with a width of 1500mm or more. The packaging of such stainless steel coils requires protection of the surface quality of the steel coils and reduces the quality problems that often occur during the storage, transportation, and hoisting of the stainless steel coils, such as deterioration of the surface quality of the steel coils or changes in the plate shape. Here is the method:

First of all, choose the paper corner protectors inside and outside the package according to the inner and outer diameters of the steel roll. Wrap a circle of paper corner protectors on the inner and outer rings of the steel roll. The corner protectors are made of wood pulp noodle paper and mixed pulp paper. The characteristics of non-breaking during inward and outward bending; paper corner protection specifications are 1. 5~2. 5X80~50X2000~40000 (mm).

Read more about A Complete Guide to SUS Stainless Steel Banding

Install the core paper in the inner core of the steel coil. At the same time, cover a layer of waterproof membrane on the core paper, the length is equal to the circumference of the inner core of the steel coil, and the width is equal to the width of the steel coil. After this, the core paper is placed in the center of the stainless steel coil to make the inner ring of the steel coil waterproof. The surface of the core paper requires the waterproof membrane to be flat and free of bubbles.

The width of the protective plate should be the same as the width of the steel coil, and the length should be 200mm larger than the circumference of the steel coil. The interface should be placed on the side, upper end and bottom of the steel coil. After that, press the lower end with the protective plate. After wrapping the outer guard plate with the steel coil, stick the joints of the outer guard plate with adhesive tape. The bonding is required to be firm and flat. At the same time, the outer corner guard ring is used to press both sides of the tape.

Try for free information about the A Complete Guide to Stainless Steel AISI 420

The width of the guard plate in the package should be consistent with the width of the steel roll, and the interface should be placed above the inner side of the steel roll. Packing iron corner protectors and end protectors are required to choose a piece smaller than the outer diameter of the steel roll and be clamped with an outer protector ring. The interface and the interface of the outer protector are at the same position and the upper end presses the lower end; the overlap of various materials is 200mm Inside.

When packaging the wooden curtain board, the wooden curtain board package must be butted and must be placed upright and flat. When the steel roll is bundled, the circumferential packing tape presses the middle of the outer corner protector. The core belts should be evenly distributed, tightened, and tightened, and the joint clips should be unified on one side. The packing belt clip should be flattened. Finally, paste the label in the middle of the two packaging belts on the upper left of the end shield. There is a lock on each packaging belt, the lock has a length of 50mm, a width of 35mm, and an opening of 10mm. The steel roll label should be filled with complete content, one of which is affixed to the end shield, while rain and a moisture-proof label are affixed, and the other is affixed to the inner shield.

Get it now:A Complete Guide to SUS Stainless Steel Banding

It refers to the narrow stainless steel coil that has been cut by the slitting machine after the cold rolling.

Remove the stainless steel narrow strip coils cut by the slitting machine group from the reel and put them on the support.

Use rust-proof paper for winding and packaging of narrow strip rolls; insert the plastic packaging bag along the outside of the narrow strip roll and pass through the inner wall of the narrow strip roll to make the plastic bag and the inner wall of the narrow strip roll evenly close to the narrow core. The outer side of the strip roll; evenly place three thin wooden boards of the same thickness on the first narrow strip roll, and then place the second strip roll.

When the last narrow strip coil stack is finished, turn the plastic bag in the narrow strip coil to the outer bottom edge of the steel coil that needs to be packaged as a whole, and then turn the outer plastic bag of the steel coil back to the inner wall of the steel coil. Bottom edge, then use scotch tape to glue the plastic bag turned to the inner circle of the steel coil tightly.

Finally, the inner and outer corner guards are placed along the circumference of the steel coil; the two ends of the steel coil are added with the lower end guard plate; the steel coil is evenly packaged and fixed as a whole.

Keep reading:A complete guide to SUS 304 stainless steel

Now, when we are about to end this guide. Hope you have noticed and understood a lot of information necessary to purchase stainless steel strip from China.

However, if I did not recommend to you the best stainless steel supplier, it would be unfair. As you see, the procurement and production of stainless steel coils is no easy task. As can be seen from this guide, it requires a stable and reliable supply chain system, a wealth of expertise in stainless steel coils, and the most important network. Therefore, to get you the best stainless steel coil solution, the ideal stainless steel coil provider in China.

Try for free information about the Aisi 304 stainless steel: the best you can find & purchase – Yaoyi

The fact now is that, obviously, you already know what you need to source stainless steel coils from China. You will also learn about all the important aspects surrounding the entire process.

Therefore, as I mentioned before, the essence of this guide is to let you understand the different elements. It is no doubt that this will enable you to make wise choices.

Most importantly, you now have the idea of a trusted and reputable stainless steel coil supplier. But anyway, if you have any questions, please feel free to contact us. Yaoyiwill provide the necessary support.

Read more:difference between Stainless Steel 316 and Stainless Steel 316l

2 inch stainless steel coil tubing is commonly used in industries such as:

Petrochemical and oil & gas: For transporting corrosive fluids, high-pressure applications, and heat exchangers.

Food and beverage: In sanitary tubing systems for processing, storage, and transportation of food and beverage products.

Water treatment: In water treatment plants, desalination facilities, and water distribution systems.

HVAC: For heating, ventilation, and air conditioning applications, such as heat exchangers and refrigerant lines.

2 inch stainless steel coil tubing is typically packaged using one of the following methods:

Wooden or plastic reels: The 2 inch stainless steel coil tubing is wound onto a reel for easy handling, storage, and transportation.

Pallets: The 2 inch stainless steel coil tubing is securely fastened to a pallet, often with protective packaging to prevent damage during transport.

Plastic or metal end caps: These caps protect the ends of the tubing, preventing contamination and damage.

The surface finishes for 3/8 stainless steel tubing coil can vary, depending on the desired appearance and application requirements. Common surface finishes include:

Annealed and pickled (AP): This finish results from the annealing and pickling process, leaving a dull, matte appearance.

Bright annealed (BA): The tubing is annealed in a controlled atmosphere, resulting in a bright, reflective surface with minimal discoloration.

Mechanical polishing: The 3/8 stainless steel tubing coil is mechanically polished to achieve a smooth, uniform surface with a specified level of roughness. This can range from a satin finish to a mirror-like shine.

Electropolishing: This electrochemical process removes a thin layer from the surface, resulting in a smooth, bright, and corrosion-resistant finish.

The surface of each stainless steel trim coil can vary due to factors such as the manufacturing process, the specific grade of stainless steel, and the intended application. Different surface finishes can provide unique characteristics, such as enhanced corrosion resistance, reduced surface roughness, or improved aesthetics.

Various techniques are used to produce different surface finishes on stainless steel trim coils, including:

Hot or cold rolling: The initial surface finish is determined by the rolling process, with hot-rolled coils having a rougher surface than cold-rolled coils.

Annealing and pickling: This process helps to remove scale and restore corrosion resistance, leaving a matte finish.

Mechanical polishing: Techniques such as buffing, grinding, or sanding can create a range of surface finishes, from satin to mirror-like.

Electropolishing: This electrochemical process produces a smooth, bright, and corrosion-resistant surface.

Coatings: Applying coatings such as lacquer or paint can provide additional protection and aesthetic appeal.

Key technical points to consider when working with stainless steel coils include:

Material selection: Choose the appropriate stainless steel grade for the specific application, considering factors such as corrosion resistance, strength, and formability.

Surface finish: Select the desired surface finish based on aesthetic requirements and application-specific needs, such as corrosion resistance or reduced surface roughness.

Coil handling: Ensure proper handling and storage techniques to prevent damage to the coil edges, surface, and shape.

Forming and fabrication: Use appropriate forming and fabrication methods to minimize stress and maintain material integrity, such as avoiding excessive bending or sharp angles.

Welding: Select suitable welding techniques and filler materials to maintain corrosion resistance and avoid defects, such as intergranular corrosion or weld cracking.

The properties of stainless steel coils are influenced by the presence and concentration of various alloying elements:

Chromium: A crucial element in stainless steel, providing corrosion resistance by forming a passive oxide layer on the surface. Higher chromium content generally results in better corrosion resistance.

Nickel: Improves ductility, toughness, and workability, and stabilizes the austenitic structure of stainless steel.

Molybdenum: Enhances corrosion resistance, particularly in chloride-containing environments, and increases strength at high temperatures.

Manganese: Contributes to strength and hardness, and can replace some of the nickel content in austenitic stainless steels, resulting in cost savings.

Silicon: Acts as a deoxidizer and can improve oxidation resistance at high temperatures.

The production process for stainless steel coils varies primarily in the composition of the raw materials and the specific rolling and annealing parameters, which are adjusted to achieve the desired mechanical properties and microstructure for each grade. For instance:

304 grade stainless steel roll: This grade is one of the most common austenitic stainless steels, containing 18-20% chromium and 8-10% nickel. The production process is adjusted to obtain a balanced combination of corrosion resistance, formability, and strength.

316 grade stainless steel roll: This grade contains molybdenum in addition to chromium and nickel, enhancing its corrosion resistance in chloride-containing environments. The production process is tailored to ensure a stable austenitic structure and improved corrosion resistance.

430 grade stainless steel coil: This is a ferritic stainless steel containing 16-18% chromium and no nickel. The production process is adjusted to achieve a ferritic microstructure, which results in magnetic properties and lower corrosion resistance compared to austenitic grades.

Different surface finishes of stainless steel coils are suitable for specific applications, based on their functional and aesthetic requirements:

Annealed and pickled (AP): Suitable for industrial applications where appearance is not a priority, such as chemical processing or heat exchanger tubing.

Bright annealed (BA): Ideal for applications requiring a bright, reflective surface, such as decorative trim, architectural features, or automotive components.

Mechanical polishing: Used in applications where aesthetics and surface smoothness are essential, such as kitchen appliances, sanitary tubing, or food processing equipment.

Electropolishing: Recommended for applications requiring high corrosion resistance and a smooth, bright surface, such as pharmaceutical or semiconductor manufacturing equipment.

When choosing the right stainless steel roll for a particular application, consider the following factors:

Corrosion resistance: Select a stainless steel grade with sufficient corrosion resistance for the specific environment and conditions of your application.

Mechanical properties: Choose a grade with the required strength, ductility, and hardness for the intended use.

Formability and weldability: Ensure that the selected grade can be easily formed, fabricated, and welded according to the requirements of your application.

Heat resistance: For high-temperature applications, choose a stainless steel grade that can maintain its mechanical and corrosion-resistant properties at the required temperatures.

Aesthetics and surface finish: Select a suitable surface finish based on the aesthetic preferences and functional needs of your application, such as reflectivity, smoothness, or corrosion resistance.

Cost considerations: Balance the cost of the stainless steel coil with the required performance characteristics, and consider alternatives that may offer similar properties at a lower price point.

Fabrication and processing of stainless steel rolls can present several challenges, including:

Work hardening: Stainless steel, particularly austenitic grades, can work harden rapidly during forming and fabrication, making it difficult to shape. To mitigate this issue, use lower-forming speeds, employ intermediate annealing, or select a more formable grade of stainless steel.

Welding: Welding stainless steel coils can lead to issues such as distortion, discoloration, or intergranular corrosion. To minimize these problems, use appropriate welding techniques, filler materials, and shielding gases, and ensure proper cleaning of the weld area.

Surface damage: During processing and handling, stainless steel coils can be susceptible to surface damage, such as scratches, dents, or contamination. To prevent this, ensure proper handling techniques, use protective packaging during transport, and maintain a clean working environment.

Stress corrosion cracking: Certain stainless steel grades can be susceptible to stress corrosion cracking in chloride-containing environments. To minimize this risk, choose a more resistant stainless steel grade, or implement measures to reduce the applied stress or the presence of chlorides.

Heat treatment processes, such as annealing, quenching, and tempering, can significantly affect the properties of stainless steel rolls by altering their microstructure and relieving internal stresses:

Annealing: This process involves heating the stainless steel to a high temperature and then cooling it slowly to room temperature. Annealing can soften the material, improve ductility, and increase its corrosion resistance.

Quenching: Rapid cooling from high temperatures can increase the hardness and strength of stainless steel coils. However, quenching can also cause brittleness and reduced ductility.

Tempering: Heating the quenched stainless steel to a specific temperature and then cooling it slowly can improve the material’s toughness, ductility, and dimensional stability.

Several advanced forming techniques can be employed to process stainless steel coils, depending on the specific application requirements:

Hydroforming: This technique uses hydraulic pressure to form stainless steel coils into complex shapes. Hydroforming can reduce material waste and tooling costs and is particularly suitable for thin-walled components.

Roll forming: A continuous bending process that gradually shapes stainless steel coils into the desired profile. Roll forming is ideal for producing long, linear components with consistent cross-sectional shapes.

Laser cutting: A non-contact cutting method that uses a high-power laser to cut complex shapes and patterns in stainless steel coils with high precision and minimal material waste.

Various surface treatments can be applied to stainless steel coils to enhance their performance, appearance, and durability:

Passivation: A chemical treatment that removes contaminants and forms a thin, protective oxide layer on the surface of stainless steel, improving its corrosion resistance.

Electroplating: The application of a thin layer of another metal, such as chromium or nickel, onto the surface of the stainless steel coil to enhance its appearance, corrosion resistance, or wear resistance.

Physical vapor deposition (PVD): A process that deposits a thin, durable coating onto the stainless steel surface, improving its aesthetics, wear resistance, and corrosion resistance. PVD coatings can include metallic, ceramic, or composite materials.

Powder coating: A dry finishing process that applies a protective and decorative coating to the stainless steel surface. Powder coatings can offer excellent corrosion resistance, color retention, and surface texture options.

The surface finish of a stainless steel coil can significantly impact its performance, appearance, and durability:

Corrosion resistance: Certain surface finishes, such as electropolishing or passivation, can improve the corrosion resistance of stainless steel by forming a protective oxide layer on the surface.

Aesthetics: The appearance of stainless steel coils can be greatly influenced by the surface finish, ranging from matte and brushed to highly reflective and mirror-like.

Friction and wear: Smooth, polished surface finishes can reduce friction and wear in applications where stainless steel components are in contact with other surfaces.

Cleanability: Some surface finishes, such as electropolishing or mechanical polishing, can create a smoother, more easily cleaned surface that is suitable for sanitary or hygienic applications.

Quality control is a crucial aspect of stainless steel coil production and processing, ensuring that the final product meets the desired specifications and performance requirements:

Raw material inspection: The quality of the raw materials used in stainless steel production significantly impacts the final product. Inspections and tests are performed to ensure that the raw materials meet the required specifications.

In-process inspection: During the production and processing of stainless steel coils, in-process inspections are carried out to monitor critical parameters, such as temperature, rolling speed, and surface quality, ensuring that the product remains within the specified tolerances.

Non-destructive testing (NDT): Techniques such as ultrasonic testing, radiographic testing, and eddy current testing can be employed to detect defects or imperfections in stainless steel coils without causing damage to the material.

Mechanical and chemical testing: Quality control also involves conducting mechanical and chemical tests to verify that the stainless steel coils meet the specified mechanical properties, chemical composition, and corrosion resistance requirements.

Surface inspection: Visual and tactile inspections, as well as advanced surface inspection techniques, can be used to identify and evaluate surface defects, such as scratches, dents, or inclusions, ensuring that the finished product meets the desired aesthetic and functional standards.

Dimensional inspection: Measurement and inspection of stainless steel coil dimensions, such as thickness, width, and coil diameter, are crucial for ensuring that the final product conforms to the required specifications.

Yaoyi, a family-owned stainless steel manufacturer, with 28+ years of experience. Get the best solution for stainless steel coils with us.