Stainless Steel Ties:Usage,Features, Types, Applications

Ewan Liao

Stainless steel ties are versatile fastening devices made from high-quality stainless steel, offering superior strength and durability for various applications. They are essential components in industries where resilience to extreme conditions is paramount, providing reliable solutions for bundling and securing items in harsh environments.

Material Testing After You Place An Stainless Steel Foil Order

Hardness Testing

Ingredient detection

Tensile Strength Test

Table of Contents

What Is the Stainless Steel Ties?

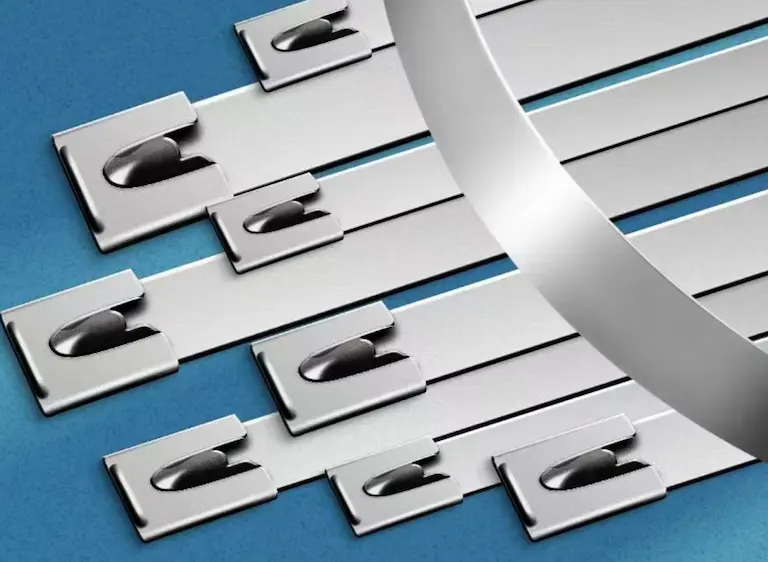

Stainless steel ties, often referred to as stainless cable ties or stainless zip ties, are fastening tools designed to secure cables, wires, and other items tightly. Unlike their plastic counterparts, they withstand extreme temperatures, UV exposure, and corrosive substances, making them ideal for both indoor and outdoor use.

These ties are constructed from stainless steel grades that offer excellent corrosion resistance and mechanical strength. They come in various lengths and widths to accommodate different bundling requirements. The self-locking mechanism ensures a secure hold, and some variants feature a coating for additional protection and easier handling.

Stainless Steel Ties: Usage

Stainless steel ties are widely used across multiple industries. In the marine sector, they secure wiring and components exposed to saltwater. The aerospace industry utilizes them for their reliability under extreme temperatures. They are also common in construction, automotive, and oil and gas industries, where stainless steel wire ties hold up under challenging conditions that would degrade standard materials.

Stainless Steel Ties: Features

Key features of stainless steel ties include:

- High Tensile Strength: Capable of securing heavy loads without breaking.

- Corrosion Resistance: Withstands exposure to chemicals, salts, and acids.

- Temperature Resilience: Operates effectively in temperatures ranging from -80°C to 538°C.

- Durability: Resistant to UV light and radiation, ensuring a long service life.

Stainless Steel Ties: Types

There are several types of stainless steel ties available:

- Uncoated Stainless Steel Ties: Ideal for high-temperature environments.

- Coated Stainless Steel Tie Wraps: Feature a non-toxic, halogen-free coating for improved safety and handling.

- Releasable Stainless Steel Ties: Allow for reuse, providing flexibility for temporary installations.

- Heavy-Duty SS Cable Ties: Designed for applications requiring extra strength.

Stainless Steel Cable Tie: Applications

Stainless steel cable ties are crucial in settings where other materials fail. They are used in:

- Oil and Gas Industry: Securing pipes and cables in corrosive environments.

- Aerospace and Automotive Sectors: Bundling wires that are exposed to extreme temperatures.

- Construction: Fastening components in outdoor installations.

- Electrical Installations: Organizing cables in areas with high fire risk due to their non-flammable nature.

read more about : How to choose 304 stainless steel Hardness that meets your requirements

Stainless Steel Cable Tie: Advantages and Disadvantages

Advantages:

- Durability: Long-lasting even in harsh conditions.

- Strength: Capable of holding heavy bundles securely.

- Resistance: Unaffected by chemicals, UV light, and extreme temperatures.

Disadvantages:

- Cost: More expensive than standard plastic ties.

- Installation Tools: May require a stainless steel zip ties tool for proper tensioning.

- Handling: Edges can be sharp; protective gloves are recommended during installation.

Stainless steel ties are indispensable for applications demanding high strength and resistance to environmental factors. By selecting the appropriate type and handling them correctly, they offer a reliable and long-term fastening solution across various industries.