Delving into the world of 316 Stainless Steel Foil, this comprehensive guide will explore everything you need to know about this versatile material. From distinguishing properties and diverse applications across industries to comparisons with other foils like 309 Stainless Steel Foil and 316L Foil, we’ll unravel it all. Delve into the potential of 316 Stainless Steel Foil in culinary endeavors, the intricate process of its manufacturing, and tips for its selection, handling, cleaning, and even recycling. Whether you’re seeking to understand its place in your next project or you’re keen on its purchase, we’ve got you covered. Join us as we navigate the fascinating world of 316 Stainless Steel Foil.

Exceptional Customer Service: We pride ourselves on providing exceptional customer service, from the initial inquiry to the final delivery of your product. Our knowledgeable and experienced team is always available to answer any questions or concerns you may have.

Long-Term Partnerships: We understand that building long-term partnerships is essential to our success.

That’s why we work closely with our customers to develop relationships based on trust, reliability, and mutual benefit. Industry Expertise: With over 15 years of experience in the stainless steel industry, we have the knowledge and expertise to help you find the right product for your unique needs.

At Yaoyi Stainless Steel Co. Ltd, we are dedicated to providing our customers with high-quality stainless steel foil, exceptional customer service, and competitive pricing. Contact us today to learn more about how we can meet your specific industrial needs.

Besides the 0.01~0.05mm stainless steel foil, you may need to purchase other stainless steel products from China, please contact us if you have any questions.

316 stainless steel foil is a thin sheet of stainless steel that is typically less than 0.25 millimeters thick. It is made from an alloy of iron, carbon, and a variety of other metals, including nickel, chromium, and molybdenum. These additional metals enhance the properties of the steel and make it more resistant to corrosion, high-temperature environments, and wear and tear.

One of the primary reasons why 316 ss foil is so popular in industrial applications is its excellent corrosion resistance. This material is highly resistant to corrosion in harsh environments, making it ideal for use in marine, aerospace, and chemical processing industries. Additionally, 316 ss foil has superior strength and durability, making it suitable for a wide range of applications, including construction, food processing equipment, and medical devices.

Overall, 316 ss is a versatile and durable material that offers a range of benefits for various industrial applications. Its unique properties make it an ideal choice for applications that require strength, durability, and resistance to corrosion.

316 ss foil has a wide range of applications across various industries, including:

Marine and Aerospace: Due to its excellent corrosion resistance, 316 stainless steel foil is often used in marine and aerospace industries for components exposed to saltwater and other harsh environments.

Food Processing Equipment: 316 ss foil is ideal for use in food processing equipment, as it is resistant to corrosion and can be easily cleaned and sanitized.

Medical and Pharmaceutical Applications: The biocompatibility and corrosion resistance of 316 stainless steel foil make it an ideal material for medical and pharmaceutical applications, including surgical instruments, implants, and drug delivery devices.

Construction: 316 ss foil is often used in construction for its strength and durability, particularly in applications where the material must withstand high stress or harsh weather conditions.

Overall, the unique properties of 316 stainless steel foil make it a versatile material that can be used in a variety of industrial applications. Its corrosion resistance, strength, and durability make it an ideal choice for components that require long-lasting performance in harsh environments.

Learn more about the “How to Find the Best Deals on 304 Stainless Steel Foil Price“

The properties of 316 stainless steel foil make it an ideal material for a wide range of industrial applications. Here are some of its key properties:

Resistance to Corrosion: 316 stainless steel foil is highly resistant to corrosion, particularly in harsh environments such as saltwater or acidic chemicals. This property makes it a popular choice for marine, aerospace, and chemical processing applications.

High-Temperature Resistance: 316 foil can withstand high temperatures without losing its strength or durability. This property makes it suitable for use in applications that require resistance to high temperatures, such as furnace components and exhaust systems.

Strength and Durability: 316 foil is stronger and more durable than many other types of stainless steel. This property makes it suitable for use in applications that require high strength and durability, such as construction and automotive industries.

Biocompatibility: 316 stainless steel foil is biocompatible, meaning it can be used in medical and pharmaceutical applications without causing adverse reactions in the human body.

Overall, the properties of 316 stainless steel foil make it an ideal material for a variety of industrial applications that require resistance to corrosion, high temperatures, and high stress. Its strength, durability, and biocompatibility make it a versatile material that can be used in a wide range of applications.

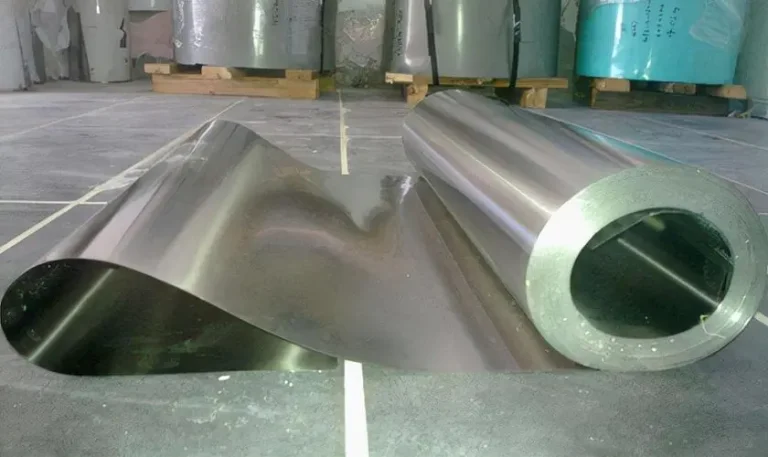

Yes, 316 stainless steel foil can be customized to meet the specific needs of different industrial applications. The customization options for 316 stainless steel foil include thickness, width, and length.

Thickness: ss 316 foil can be customized to various thicknesses, ranging from very thin foils (less than 0.001 inch) to thicker sheets (up to 0.25 inch). Custom thicknesses can be selected based on the specific needs of an application, such as strength requirements or flexibility.

Width: 316 stainless steel foil can also be customized to different widths. This can be useful for applications where a specific width is required, such as in the construction of building facades or in electrical components.

Length: 316 stainless steel foil can be supplied in custom lengths to meet the needs of specific applications. Custom lengths are useful for applications where the material needs to be cut to a specific size or where longer lengths are required for processing or manufacturing.

Customizing 316 stainless steel foil can help meet the specific needs of various industrial applications, improving efficiency, and reducing waste. For example, by customizing the thickness of the foil to match the specific strength requirements of an application, manufacturers can reduce the amount of material used, resulting in cost savings and reduced waste.

Overall, customizing 316 ss foil is a useful tool for manufacturers to ensure that the material meets their specific industrial needs.

When it comes to buying 316 stainless steel foil, there are several factors to consider when choosing a supplier:

Price: The cost of 316 ss foil can vary depending on the supplier and the customization options chosen. It is important to compare prices from different suppliers to ensure that you are getting a fair price for the material.

Quality: The quality of the 316 ss foil is another important factor to consider. Look for suppliers that offer high-quality material that meets your specific requirements. You can also check for certifications such as ISO or ASTM to ensure that the material meets industry standards.

Lead Times: The lead time, or the amount of time it takes for the supplier to deliver the material, is also an important consideration. Make sure to choose a supplier that can provide the 316 stainless steel foil within the required timeframe. Some reputable suppliers that offer high-quality 316 stainless steel foil include:

Yaoyi Stainless Steel Co., Inc.

Ulbrich Stainless Steels & Special Metals Inc.

Gibbs Wire & Steel Company, Inc.

Rolled Steel Products Corporation

Atlantic Stainless Co., Inc.

VDM Metals USA, LLC.

When choosing a supplier, it is important to consider these factors and to research different suppliers to find the one that best meets your needs. By choosing a reputable supplier, you can ensure that you are getting high-quality 316 stainless steel foil that meets your specific industrial requirements.

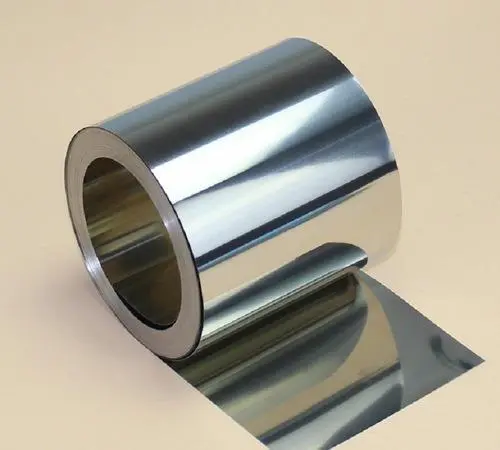

316 stainless steel foil can come in several finishes to suit different applications. The most common include the 2B (smooth) finish, which is used for general applications; the #4 finish, which has a brushed look and is often used in architecture and kitchen appliances; and the BA (bright annealed) finish, which has a mirror-like appearance and is used when a highly reflective surface is required.

Due to its high corrosion resistance and durability, 316 stainless steel foil is often used in a variety of industries. These include chemical processing, marine applications, food and beverage production, pharmaceutical equipment, and architectural elements in corrosive environments.

To ensure you’re getting a fair price, it’s advisable to get quotes from several different suppliers. Consider the total cost, including shipping and any potential import duties. Keep in mind that the cheapest option may not always be the best in terms of quality or service, so consider all factors before making a decision.

Yes, many manufacturers offer customisation options for 316 stainless steel foil. This can include specific thicknesses, widths, and finishes to meet unique application requirements. However, customisation may affect the price and lead time of the product.

316 stainless steel foil stands out for its superior quality. In this section, we'll explore how it compares to other steel foils.

Unlike mild steel foil, 316 stainless steel foil has a high resistance to rust and corrosion, making it a preferred choice in harsh environments.

Compared to carbon steel foil, the SS 316 Stainless foil offers enhanced durability and longevity.

The 316l stainless steel foil has excellent tolerance to high temperatures, unlike other foils that might deteriorate or lose their properties.

Though it may be more expensive than mild steel foil, the 316 grade offers better value over time due to its durability and minimal maintenance requirements.

With CNC systems controlling thickness tolerance within 0.005mm, 316 stainless steel foil ensures more precision than other steel foils.

316 stainless steel foil is more versatile and adaptable for various applications compared to other steel foils, like carbon steel foil.

When it comes to stainless steel foil for cooking, 316 type is considered safer and adheres to higher hygiene standards.

The production of 316 stainless steel foil is more environmentally friendly compared to other foils, contributing to sustainable practices.

SS 316 Stainless foil's quality far surpasses other steel foils in various aspects such as corrosion resistance, durability, and versatility. Its unique properties make it an ideal choice for diverse applications.

316l stainless steel foil is a low-carbon variant of standard 316. Let's explore the differences.

316l contains less carbon compared to 316, enhancing its resistance to corrosion.

Though the difference is minimal, 316l offers slightly better mechanical properties, making it suitable for specific industrial applications.

316l stainless steel foil has enhanced weldability due to its low carbon content, making it preferable in welded structures.

The 316l type offers increased resistance to chloride corrosion compared to 316, making it ideal for marine applications like ss foil ship construction.

316l shows less sensitivity to temperature variations, providing better performance in variable temperature conditions.

While 316 is versatile, 316l is specifically chosen for its enhanced properties in particular applications.

316l might be slightly more expensive than 316, but it's readily available from reliable suppliers like Yaoyi.

316l stainless steel foil stands as a specialized variant of 316, with unique characteristics such as improved weldability and corrosion resistance. It's a tailored solution for specific needs.

Using stainless steel foil for cooking is becoming increasingly popular. Let's explore why the 316 type is an excellent choice.

316 stainless steel foil offers top-notch safety and hygiene standards, making it ideal for cooking applications.

Unlike mild steel foil, the 316 type resists corrosion even in the presence of food acids and salts, ensuring long-lasting use.

316 stainless steel foil ensures even heat distribution, leading to consistent cooking results.

The non-reactive nature of SS 316 Stainless foil ensures that it doesn't alter the flavor or color of the food.

316 stainless steel foil adheres to health standards, making it a preferred choice over aluminum foils in many cases.

Using 316 stainless steel foil contributes to sustainable cooking practices, reducing waste.

From grilling to steaming, 316 stainless steel foil is versatile and can be used in various cooking methods.

While slightly more expensive than other foils, the 316 type is readily available and offers value for money.

316 stainless steel foil stands out as an exceptional choice for cooking, offering benefits like corrosion resistance, heat distribution, and environmental friendliness.

Thickness tolerance is a crucial factor in steel foil applications. Yaoyi's 316 stainless steel foil has unique features in this regard.

Yaoyi Stainless employs a CNC system to control the thickness tolerance of the SS 316 Stainless foil within 0.005mm, ensuring precise measurements.

Precise thickness tolerance in stainless steel foil roll ensures consistency, quality, and performance in various applications.

Yaoyi's tolerance standards are well above industry norms, offering a significant advantage in quality.

316l stainless steel foil with controlled thickness tolerance is ideal for industries that demand high precision, such as aerospace and electronics.

Yaoyi implements strict quality control, further backed by advanced laboratory equipment to verify the thickness of each stainless steel foil roll.

Yaoyi's 316 stainless steel foil's thickness tolerance stands as a benchmark in the industry, offering unparalleled precision and quality, enhancing its suitability for various applications.

The 316 stainless steel foil is renowned for its corrosion resistance, durability, and versatile uses. This steel foil finds applications in various industries and purposes.

Utilizing SS 316 Stainless foil in industrial environments is common due to its resistance to corrosive elements and its ability to withstand high temperatures.

In the food industry, this foil is used for cooking and packaging because of its safety and hygiene features.

316l stainless steel foil, a variation of 316, is often used in medical devices for its biocompatibility.

SS 316 Stainless foil is widely used in marine environments, known as ss foil ship, thanks to its corrosion resistance.

This foil is also used in the electronics industry for shielding and other critical applications.

316 stainless steel foil plays an essential role in construction, providing strength and aesthetics to structures.

In the automotive industry, it is used for its durability and ability to resist wear and tear.

Purchasing 316 stainless steel foil is simplified by suppliers like Yaoyi, guaranteeing quality by the source and offering the product in various dimensions.

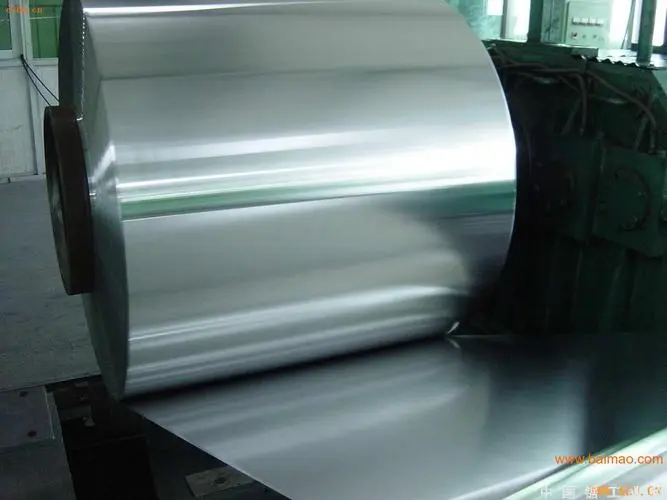

The production of 316 stainless steel foil is a complex process that ensures quality at every step. Here’s a detailed look:

Yaoyi’s stainless steel foil production uses hot-rolled coils from Baosteel, guaranteeing quality right from the source.

The hot-rolling process helps in forming the steel foil sheet, providing excellent strength and durability.

Cold rolling ensures accurate thickness and a smooth surface, further enhancing the quality of the stainless steel foil roll.

The heat treatment stage optimizes the mechanical properties of the SS 316 Stainless foil, ensuring resilience and performance.

Different surface finishes are available, catering to various applications and aesthetics.

Yaoyi implements rigorous inspection and quality control measures in accordance with ISO 9001, ensuring the product meets all standards.

Utilizing CNC systems, Yaoyi controls the thickness tolerance of the stainless steel foil within 0.005mm.

Careful packing and delivery practices ensure that the stainless steel foil reaches the customer without any damage or quality loss.

The production process of 316 stainless steel foil at Yaoyi incorporates state-of-the-art technology and stringent quality control, making the product reliable and top-notch.

316 stainless steel foil’s versatility makes it suitable for numerous industries. Let’s explore some key applications:

316 stainless steel foil’s resistance to corrosion makes it ideal for marine applications, such as ss foil ship components.

Its non-reactive nature and adherence to hygiene standards make 316 type suitable for food processing equipment and stainless steel foil for cooking.

316 stainless steel foil is used in surgical instruments and pharmaceutical equipment due to its resistance to chemical reactions.

The precision thickness control of Yaoyi’s 316 stainless steel foil meets the demands of aerospace applications.

316l stainless steel foil is commonly used in electronic components due to its specific properties.

The 316 type is used in construction, especially in environments where corrosion resistance is a priority.

From vehicle bodies to interior components, 316 stainless steel foil plays a vital role in the automotive industry.

316 stainless steel foil finds broad applications across various industries due to its unique properties, including corrosion resistance, strength, and adaptability.

Understanding the chemical composition of 316 stainless steel foil is vital for ensuring quality, durability, and performance. Here’s how Yaoyi does it:

Yaoyi employs a spectrometer imported from Germany to accurately analyze the chemical composition of the stainless steel foil.

Accurate chemical analysis ensures that the steel foil sheet complies with standards, making it suitable for various applications like steel foil ship components.

The primary elements in 316 stainless steel foil include Chromium, Nickel, Molybdenum, and small amounts of Carbon and other additives.

The specific composition of SS 316 Stainless foil gives it superior corrosion resistance, making it ideal for marine and other harsh environments.

The chemical composition aligns with industry standards, including ASTM specifications.

Yaoyi’s rigorous quality control measures include chemical analysis, ensuring that each batch of stainless steel foil roll meets the required standards.

Analyzing the chemical composition of 316 stainless steel foil is pivotal in ensuring the material’s integrity, performance, and compliance with global standards.

Choosing the right type of 316 stainless steel foil is essential for project success. Here’s a guide:

Identify the specific need, such as stainless steel foil for cooking or corrosion-resistant applications like ss foil ship construction.

Consider the thickness required, keeping in mind Yaoyi’s ability to control thickness tolerance within 0.005mm.

Select the desired surface finish, which can vary based on aesthetic and functional requirements.

Ensure that the selected 316 stainless steel foil complies with relevant industry standards and certifications.

When in doubt, consult with experts like Yaoyi, who have comprehensive knowledge of 316l stainless steel foil and can provide tailored solutions.

Choosing the right type of 316 stainless steel foil involves understanding the specific application, required thickness, finish, and compliance with standards. Professional consultation can ease the process.