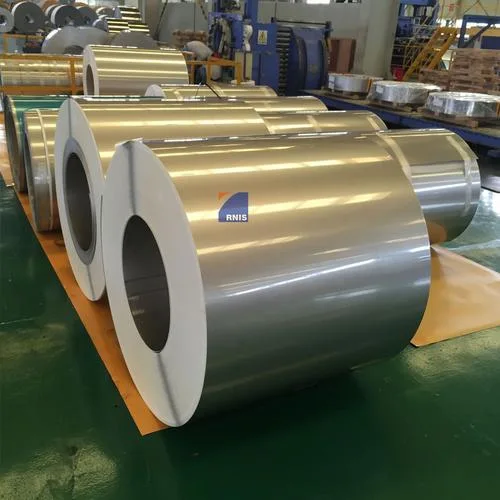

Half-hard 304 stainless steel coil or semi-hard strip of stainless steel 304, also known as 1/2 hard 304 stainless steel coil is a versatile metal with many applications in a variety of industries. In this article, we will explore its characteristics, the differences between full-hard and half-hard steel, as well as common applications of this type of material. We will also discuss the benefits of making use of half-hard 304 stainless steel coils and look at the various manufacturing methods that are associated with this particular material.

In the realm of stainless steel manufacturing, the 304 stainless steel coil stands as a testament to resilience and quality. This product, crafted by the seasoned professionals at Yaoyi, a leading stainless steel manufacturer, has been a cornerstone in various industries for over two decades. The 304 stainless steel coil, known for its robustness and longevity, has been a key player in the stainless steel industry, contributing to the growth and development of various sectors.

The chemical composition of 304 stainless steel includes chromium, nickel, manganese, silicon, carbon, and small amounts of other elements. This composition provides the alloy with excellent corrosion resistance and mechanical properties. The balance of these elements is critical to achieving the desired half-hard state in the final product.

When 304 stainless steel undergoes cold-working and annealing processes, it achieves a moderate level of hardness, which is referred to as half-hard 304 SS coil. This state offers a balance between soft (annealed) and full-hard (cold-worked) stainless steel, providing excellent strength, hardness, and ductility. The 304 half-hard stainless steel properties make it suitable for a range of applications, from automotive parts to kitchen appliances.

One of the main benefits of 304 stainless steel is its excellent corrosion resistance. Due to the high chromium content, a protective oxide layer forms on the surface, which prevents the material from corroding. This makes half-hard 304 stainless steel ideal for applications where exposure to corrosive elements is a concern.

Learn more about the How to Find the Best Deals on 316 Stainless Steel Foil Price.

Half-hard stainless steel is typically used in applications that require a balance between strength and formability, while full-hard stainless steel is more suitable for applications that prioritize maximum strength and durability. Understanding the differences between these two states of stainless steel can help you make informed decisions when selecting materials for your projects.

The balance between strength, hardness, and ductility makes half-hard 304 stainless steel an ideal material for manufacturing springs. These springs can be found in various industries, such as automotive, aerospace, and consumer electronics.

Half-hard 304 stainless steel offers a lightweight and durable solution for various parts in vehicles, helping to improve fuel efficiency and reduce maintenance costs.

Half-hard 304 stainless steel offers a lightweight and durable solution for various parts in vehicles, helping to improve fuel efficiency and reduce maintenance costs.

The semi-hard 304 stainless steel strip is popular for manufacturing kitchen appliances and utensils due to its durability, corrosion resistance, and ease of cleaning. Products made from this material include cookware, cutlery, and kitchen sinks.

With its excellent biocompatibility and resistance to staining, 304 1/2 hard stainless steel is commonly used in the fabrication of medical devices, such as surgical instruments and implants. The corrosion resistance and cleanliness of this material make it ideal for maintaining a sterile environment in medical settings.

This allows for complex shapes and designs to be created, providing flexibility in the production of different products.

The mechanical properties of half-hard 304 stainless steel, such as its strength and hardness, contribute to its durability. This means that products made from this material can withstand wear and tear, providing long-lasting solutions for various applications.This can help reduce maintenance costs and prolong the lifespan of products made from this material.

The appearance of half-hard 304 stainless steel is another advantage, as it can be polished to achieve a mirror-like finish, providing an attractive and modern look. This is especially important for applications where aesthetics play a significant role, such as in kitchen appliances or architectural designs.

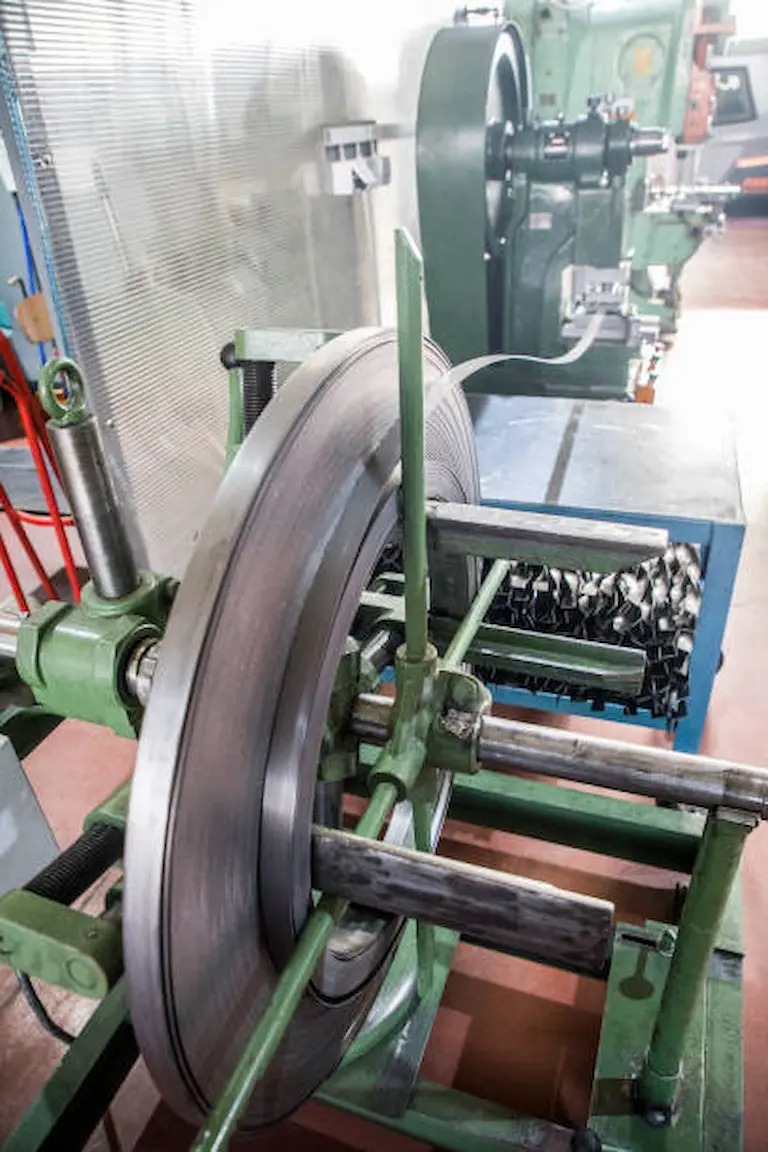

The process of cold rolling involves passing the stainless steel through a series of rollers, which reduces its thickness and increases its strength and hardness. This process helps achieve the desired half-hard state in the final product.

After cold rolling, the stainless steel undergoes an annealing process, which involves heating the material to a specific temperature and then allowing it to cool slowly. This controlled cooling process softens the steel, improving its ductility and making it more workable.

Once the desired half-hard state has been achieved, the stainless steel coil can be slit into narrow strips or cut into sheets, depending on the intended application. This process ensures the final product’s dimensions meet the necessary specifications.

To obtain the half-hard 304 stainless steel coil wholesale price, follow these steps while keeping the keyword in mind:

Research suppliers: Begin by searching online for reputable suppliers, manufacturers, or distributors that offer 1/2 hard 304 stainless steel coil at wholesale prices. Check their websites, read reviews, and gather information about their product offerings and pricing structures.

Contact suppliers: Reach out to the suppliers you have identified, inquiring about their half-hard 304 stainless steel coil wholesale prices. Be sure to provide the necessary specifications, such as thickness, width, and the quantity you require.

Request quotes: Request price quotes from multiple suppliers to get a range of wholesale prices for half-hard 304 stainless steel coil. Comparing quotes will help you find the best deal and give you more leverage during negotiations.

Negotiate: Don’t hesitate to negotiate for better half-hard 304 ss coil wholesale prices or additional services, such as delivery, packaging, or payment terms. Suppliers may be willing to provide better prices or extra services for large orders or long-term business relationships.

Evaluate offers: Carefully evaluate each offer based on the half-hard 304 stainless steel coil wholesale price, product quality, supplier reputation, and any additional services provided. Keep in mind that the lowest price may not always be the best option if it compromises quality or service.

Place your order: Once you have selected a supplier with a competitive 1/2 hard 304 stainless steel coil wholesale price, place your order and finalize the payment and delivery arrangements.

By following these steps, you can find the best half-hard 304 stainless steel coil wholesale price that meets your requirements. Keep in mind that wholesale prices can vary depending on factors like market conditions, material availability, and order size. Regularly monitoring market trends and maintaining strong relationships with suppliers can help you secure the best possible prices for your purchases.

To wholesale half-hard 304 stainless steel coil, follow these steps:

To find the best half-hard 304 stainless steel coil manufacturer, follow these steps: Research: Conduct an initial online search to identify reputable half-hard 304 stainless steel coil manufacturers.

Identifying 304 stainless steel can be a complex task without the proper tools or knowledge. However, several methods can be used to verify its authenticity.

One of the most accurate ways to identify 304 stainless steel is through chemical analysis. This process involves testing the material to determine its chemical composition. 304 stainless steel is made up of 18% chromium and 8% nickel, which gives it its unique corrosion-resistant properties.

As mentioned earlier, 304 stainless steel is generally non-magnetic. Therefore, a simple magnet test can be a quick and easy way to identify it. If the material is magnetic, it is likely not 304 stainless steel.

The spark test involves grinding a piece of the material on a grinding wheel and observing the sparks. 304 stainless steel produces a specific pattern and color of sparks that can be used to identify it.

304 stainless steel is resistant to most forms of acid, including nitric acid. If the material does not react or shows minimal reaction when exposed to nitric acid, it is likely 304 stainless steel.

Identifying 304 stainless steel requires a combination of chemical analysis, magnetic testing, spark testing, and nitric acid testing. These methods, when used correctly, can accurately determine if a material is 304 stainless steel.

The longevity of 304 stainless steel is one

of its most appealing features. Its lifespan can vary greatly depending on the environment it’s used in and how it’s maintained.

In indoor environments, 304 stainless steel can last indefinitely with proper care. This includes regular cleaning and avoiding contact with harsh chemicals that can damage its surface.

When used outdoors, 304 stainless steel’s lifespan can be affected by factors such as exposure to saltwater or acidic rain. However, even in these conditions, it can last for decades with proper maintenance.

In industrial applications, the lifespan of 304 stainless steel can be significantly reduced due to constant exposure to harsh chemicals and high temperatures. However, with regular maintenance and proper use, it can still last for many years.

The lifespan of 304 stainless steel is highly dependent on the conditions it’s exposed to and how it’s maintained. However, with proper care, it can last for decades, making it a cost-effective choice for many applications.

Testing 304 stainless steel is crucial to ensure its quality and authenticity. There are several methods that can be used to test this material.

The spark test involves grinding a piece of the material on a grinding wheel and observing the sparks. 304 stainless steel produces a specific pattern and color of sparks that can be used to identify it.

304 stainless steel is resistant to most forms of acid, including nitric acid. If the material does not react or shows minimal reaction when exposed to nitric acid, it is likely 304 stainless steel.

As mentioned earlier, 304 stainless steel is generally non-magnetic. Therefore, a simple magnet test can be a quick and easy way to identify it. If the material is magnetic, it is likely not 304 stainless steel.

One of the most accurate ways to identify 304 stainless steel is through chemical analysis. This process involves testing the material to determine its chemical composition. 304 stainless steel is made up of 18% chromium and 8% nickel, which gives it its unique corrosion-resistant properties.

Testing 304 stainless steel requires a combination of spark testing, nitric acid testing, magnetic testing, and chemical analysis. These methods, when used correctly, can accurately determine if a material is 304 stainless steel.

Yes, 304 stainless steel does contain nickel. In fact, it typically contains between 8-10.5% nickel. This element plays a crucial role in enhancing the material’s corrosion resistance, making it an ideal choice for a wide range of applications.

Nickel helps to enhance the overall corrosion resistance of 304 stainless steel. It does this by promoting the formation of a protective, passive layer on the surface of the steel. This layer prevents further oxidation, protecting the material from corrosive elements.

While nickel enhances the performance of 304 stainless steel, it’s worth noting that some people are allergic to nickel. However, the nickel in stainless steel is tightly bound within the material’s structure, reducing the risk of exposure and allergic reactions.

304 stainless steel does contain nickel, which enhances its corrosion resistance. However, the nickel is tightly bound within the material, reducing the risk of exposure and allergic reactions.

The cost of a coil of steel can vary greatly depending on several factors, including the type of steel, the size of the coil, and the current market conditions. For 304 stainless steel coil, the price can range from $1000 to $3000 per ton, depending on the thickness and width of the coil.

The price of a coil of steel is influenced by several factors. These include the type of steel, the size of the coil, and the current market conditions.

Different types of steel have different prices. For instance, 304 stainless steel, known for its excellent corrosion resistance and durability, is generally more expensive than other types of steel.

The size of the coil also affects its price. Larger coils require more material and are therefore more expensive.

The price of steel is also influenced by market conditions such as supply and demand, the cost of raw materials, and economic factors.

The cost of a coil of steel can vary greatly depending on several factors. For 304 stainless steel coil, the price can range from $1000 to $3000 per ton, depending on the thickness and width of the coil.

The price of 304 stainless steel coil in India can vary greatly depending on several factors, including the size of the coil, the current market conditions, and the supplier. On average, the price can range from INR 185 to INR 250 per Kg.

The price of 304 stainless steel coil in India is influenced by several factors. These include the size of the coil, the current market conditions, and the supplier.

The size of the coil affects its price. Larger coils require more material and are therefore more expensive.

The price of steel is also influenced by market conditions such as supply and demand, the cost of raw materials, and economic factors.

The price can also vary depending on the supplier. Some suppliers may offer lower prices due to bulk discounts or other factors.

The price of 304 stainless steel coil in India can vary greatly depending on several factors. On average, the price can range from INR 185 to INR 250 per Kg.

The price of 304 stainless steel per pound can vary greatly depending on the current market conditions and the supplier. On average, the price can range from $0.5 to $1.5 per pound.

The price of 304 stainless steel per pound is influenced by several factors. These include the current market conditions and the supplier.

The price of steel is heavily influenced by market conditions such as supply and demand, the cost of raw materials, and economic factors.

The price can also vary depending on the supplier. Some suppliers may offer lower prices due to bulk discounts or other factors.

The price of 304 stainless steel per pound can vary greatly depending on several factors. On average, the price can range from $0.5 to $1.5 per pound.

Identifying 304 stainless steel can be a complex task without the proper tools or knowledge. However, several methods can be used to verify its authenticity.

One of the most accurate ways to identify 304 stainless steel is through chemical analysis. This process involves testing the material to determine its chemical composition. 304 stainless steel is made up of 18% chromium and 8% nickel, which gives it its unique corrosion-resistant properties.

As mentioned earlier, 304 stainless steel is generally non-magnetic. Therefore, a simple magnet test can be a quick and easy way to identify it. If the material is magnetic, it is likely not 304 stainless steel.

The spark test involves grinding a piece of the material on a grinding wheel and observing the sparks. 304 stainless steel produces a specific pattern and color of sparks that can be used to identify it.

304 stainless steel is resistant to most forms of acid, including nitric acid. If the material does not react or shows minimal reaction when exposed to nitric acid, it is likely 304 stainless steel.

304 stainless steel can be purchased from a variety of sources, including steel distributors, online retailers, and direct from manufacturers. One such reliable source is Yaoyi, a leading manufacturer of 304 stainless steel coil with over 25 years of experience in the industry.

Steel distributors often carry a wide range of steel products, including 304 stainless steel. They can often provide custom sizes and finishes, and may offer volume discounts.

Online retailers such as Alibaba and Amazon also carry 304 stainless steel products. These platforms offer the convenience of shopping from home and having the products delivered directly to your door.

Purchasing directly from manufacturers can often provide the best prices, especially for

large orders. Manufacturers like Yaoyi also offer the added benefit of direct support and technical expertise.

The lifespan of 304 stainless steel is one of its most appealing features. Its lifespan can vary greatly depending on the environment it’s used in and how it’s maintained.

In indoor environments, 304 stainless steel can last indefinitely with proper care. This includes regular cleaning and avoiding contact with harsh chemicals that can damage its surface.

When used outdoors, 304 stainless steel’s lifespan can be affected by factors such as exposure to saltwater or acidic rain. However, even in these conditions, it can last for decades with proper maintenance.

In industrial applications, the lifespan of 304 stainless steel can be significantly reduced due to constant exposure to harsh chemicals and high temperatures. However, with regular maintenance and proper use, it can still last for many years.

The lifespan of 304 stainless steel is highly dependent on the conditions it’s exposed to and how it’s maintained. However, with proper care, it can last for decades, making it a cost-effective choice for many applications.

304 stainless steel is known for its excellent corrosion resistance, which is largely due to its chromium content. However, it’s not completely immune to rust. The time it takes for 304 stainless steel to rust can vary greatly depending on the environment and the conditions it’s exposed to.

The cost of 304 stainless steel can fluctuate due to several factors, including market conditions, quantity ordered, and supplier pricing policies. It’s essential to consider these factors when estimating the cost of 304 stainless steel coil.

Explain how market conditions, such as supply and demand dynamics, can influence the price of stainless steel. Mention that global economic trends and fluctuations in raw material prices can also impact the cost.

Discuss the concept of economies of scale, highlighting how larger order quantities often lead to lower unit costs due to bulk discounts and reduced production costs.

Explain that different suppliers may offer varying pricing structures based on their overhead costs, geographic location, reputation, and market positioning. Emphasize the importance of obtaining quotes from multiple suppliers for accurate cost comparisons.

Summarize the factors that can influence the cost of 304 stainless steel, including market conditions, order quantity, and supplier pricing policies. Encourage readers to conduct thorough research and obtain quotes from reputable suppliers to determine the current pricing for 304 stainless steel coil.

Clarify the common misconception surrounding the magnetic properties of 304 stainless steel, which is often mistaken as a fully non-magnetic material.

Explain that 304 stainless steel falls under the category of austenitic stainless steels, which generally exhibit low magnetic permeability.

Discuss how the crystal structure and composition of 304 stainless steel can lead to slight magnetism under certain conditions, such as cold working or deformation.

Highlight that the magnetic response of 304 stainless steel is typically weak and not significant enough to affect its performance in most applications.

Summarize that while 304 stainless steel is not considered fully non-magnetic, its magnetic properties are generally negligible in practical applications. Emphasize that the slight magnetism should not be a concern in most use cases.

Address the common question regarding the magnetic properties of both 304 and 316 stainless steel, comparing their magnetic responses.

Reiterate that 304 stainless steel is generally considered non-magnetic, with only slight magnetism possible under specific circumstances.

Explain that 316 stainless steel, similar to 304, is also generally considered non-magnetic. However, it may exhibit slight magnetism when cold worked or deformed.

Summarize that both 304 and 316 stainless steel are generally considered non-magnetic, with only slight magnetism possible under specific conditions. Emphasize that this characteristic does not significantly impact their performance in most applications.

Address the question regarding the presence of aluminum in 304 stainless steel.

Explain that 304 stainless steel is primarily composed of iron, chromium, and nickel, with trace amounts of other elements. Clarify that aluminum is not typically a component of 304 stainless steel.

Discuss that while aluminum is not present in 304 stainless steel, it is used in other stainless steel grades to enhance certain properties, such as heat resistance.

Summarize that 304 stainless steel does not typically contain aluminum. However, aluminum is used in other stainless steel grades to enhance certain properties.

While stainless steel is not known for its electrical conductivity, it does have some degree of conductivity, which can vary based on the specific grade and composition of the steel.

Explain that 304 stainless steel does conduct electricity, but its conductivity is much lower than that of metals like copper or aluminum.

Discuss how factors such as temperature and alloy composition can affect the electrical conductivity of 304 stainless steel.

Provide examples of applications where the electrical conductivity of 304 stainless steel may be relevant, such as in the manufacturing of certain electrical components.

Summarize that while 304 stainless steel is not known for its electrical conductivity, it does conduct electricity to some extent. However, its conductivity is much lower than that of many other metals.

The strength of stainless steel can vary based on the specific grade and composition. In this section, compare the strength of 304 and 316 stainless steel.

Discuss the tensile strength of both 304 and 316 stainless steel, explaining that while both grades have high tensile strength, 316 generally has a slightly higher tensile strength due to its molybdenum content.

Compare the yield strength of 304 and 316 stainless steel, again noting that 316 typically has a slightly higher yield strength.

Provide examples of applications where the strength of the stainless steel grade may be a critical factor, and discuss why one grade might be chosen over the other in these scenarios.

Summarize that while both 304 and 316 stainless steel are strong and durable, 316 stainless steel typically has a slightly higher tensile and yield strength due to its molybdenum content.

Address the question regarding the presence of cobalt in 304 stainless steel.

Explain that 304 stainless steel is primarily composed of iron, chromium, and nickel, with trace amounts of other elements. Clarify that cobalt is not typically a component of 304 stainless steel.

Discuss that while cobalt is not present in 304 stainless steel, it is used in other stainless steel grades and metal alloys for its unique properties, such as improved hardness and high-temperature stability.

Summarize that 304 stainless steel does not typically contain cobalt. However, cobalt is found in other stainless steel grades and metal alloys where it enhances certain properties.

Half-hard 304 stainless steel coils offer a balance between strength, hardness, and ductility, making them ideal for a wide range of applications across various industries. Understanding the properties, differences between half-hard and full-hard stainless steel, and the benefits of using this material can help you make informed decisions when selecting materials for your projects.

In conclusion, 304 stainless steel coil is a versatile and widely used material known for its excellent corrosion resistance, formability, and weldability. Its cost-effectiveness, longevity, and non-toxic nature make it a preferred choice for a wide range of applications, from kitchen appliances to industrial equipment.

For more information on 304 stainless steel coil and other stainless steel products, visit our blog and explore our wide range of articles on the subject.

For inquiries or to purchase 304 stainless steel coil, contact us today. Our team of experts is ready to assist you with all your stainless steel needs.

Remember, when it comes to stainless steel, it’s not just about the material—it’s about the right material for your specific needs. And at Yaoyi, we’re here to help you make the right choice.

Please note that while this article provides a general overview of 304 stainless steel coil, it’s always important to consult with a material specialist or engineer for specific applications.

Thank you for reading, and stay tuned for more informative articles on stainless steel and its applications.