Myriad obtains reliable quality raw materials from high-quality suppliers, and then sells 201 stainless steel products with excellent quality and favorable prices through a unique production process. Our products will help you greatly reduce the cost of purchasing. It means you can regard us as a reliable partner, not just a supplier. More importantly, you can put more energy into marketing and get more profits.

If you encounter a problem in the procurement process, Myriad will always solve it with you, provide you with help, and better solutions.

Thanks to the efforts of the R&D team, we can use exclusive formulas and unique processes, which also allows our products to provide customers with stronger advantages and competitiveness.

If You have some problems when you purchase 201 stainless steel, then this guide is right for you. This definitive guide will help you solve most of your problems on 201 stainless steel. Especially when you want to avoid some traps, you would better Keep reading:

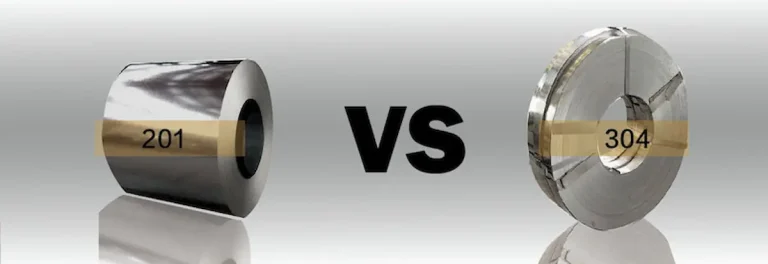

201 stainless steel is currently the cheapest type of cold-rolled stainless steel on the market. By replacing nickel with elements such as manganese and nitrogen, 200 series austenitic stainless steels were developed.

For example, the chromium content of 201 stainless steel is 16-18 and the nickel content is only 0.3-1.2. The expensive chromium and nickel are replaced by cheap elements such as manganese and nitrogen. In addition, the production cost of 201 stainless steel is cheaper than that of 301 stainless steel and 304 stainless steel.

Though the production cost is low, 201 stainless steel still has good corrosion resistance, as well as hot and cold processing performance, which is enough to replace the 304 stainless steel products used in indoor, inland cities, and outdoor environments with low corrosiveness.

A few years ago, Yaoyi has applied for a patent. It is a patent on the production of 201 stainless steel through element replacement. Products produced in this way can get special properties, in addition, it will not rust outdoors for more than 20 years.

After that, Yaoyi has developed J1, J3 and J4 stainless steel. These types of stainless steel, under the same material and hardness, the elongation rate is more than 10% higher than similar products.

No. It has certain acid and alkali resistance, high density, no bubbles, no pinholes, etc. It is used to produce high-quality materials for various watch cases and watchband bottom covers. Mainly used to make decorative tubes, industrial tubes, and some shallow stretched products.

However, food grade stainless steel is generally required to have much lower lead content in stainless steel materials than ordinary stainless steel. 201 stainless steel chemical composition bai points: (C)carbon: ≤0.15, (Si) silicon du:≤1.00, (Mn) manganese:5.5~7.50, (Cr) chromium: 16.0~18.0, (N) nitrogen:≤0.25, (P) phosphorus:≤0.060, (S) Sulfur:≤0.030,(Ni) Nickel: 3.5-5.5. Above all, it does not belong to food-grade stainless steel.

AISI 301 Equivalent: Components, Processing, and Applications

Omit the fatigue strength, 201 has a higher hardness, but its toughness and fatigue resistance are not as good as 304.

Because 304 stainless steel is chromium-nickel stainless steel, and 201 ss is low-nickel stainless steel, the price of 304 stainless steel is higher than that of 201.

201 has higher manganese content, the surface is very bright with dark and bright, higher manganese content is easy to rust. 304 stainless steel contains more chromium, the surface is matte and does not rust.

Stainless steel is not easy to rust because the chromium-rich oxide formed on the surface of the steel body can protect the steel body. 201 stainless steel material belongs to high manganese stainless steel, which has higher hardness, high carbon, and low nickel than 304 stainless steel. In the same outdoor environment without washing, 304 stainless steel will not rust for 3-4 years, and 201 stainless steel will grow rust after 6 months.

The main difference between 201 and 304 stainless steel plate is the nickel content: The composition of 201 is 17Cr-4.5Ni-6Mn-N, which is an alternative to 301 stainless steel. It is magnetic after cold working, Used in railway vehicles. The composition of 304 is 18Cr-9Ni, which is the most widely used stainless steel and heat-resistant steel. For food production equipment, general chemical equipment, nuclear energy, etc..

AISI 301 Properties: Characteristics, Compounds, and Applications

201 stainless steel is a kind of austenitic stainless steel. It is formed by using nitrogen and manganese to replace part of nickel to form the austenitic phase.

Due to the volatility of nickel prices, many producers are prompted to find another austenitic stainless steel substitute with similar properties to 304 stainless steel. In the early 1930s, the original chromium-manganese austenitic stainless steel was produced, and manganese in the steel replaced part of the nickel. Since then, more research has been conducted on the specific composition ratios. Nitrogen and copper are used to control elements such as carbon and sulfur, which strongly affect the properties of the material. Finally, the 200 series is available.

The main steel grades of 200 series stainless steel are J1, J3, J4, 201, 202. There are also 200 grades with lower nickel content control. As for 201C, it is the 201 stainless steel extension developed by individual steel plants in China at this later stage. The national standard of 201 is 1Cr17Mn6Ni5N, and 201C continues to decrease based on 201 The content of nickel increases the content of manganese.

The success of the application of 200 series stainless steel is that it is possible to replace 304 stainless steel in some specific applications. Most of the 200 series stainless steel sold in the Chinese market has almost no control of sulfur and carbon content by national standards, and manganese (and Nitrogen) replace part or all the nickel to produce austenitic stainless steel with lower nickel content.

The disadvantage of this series of materials is that the 18% chromium content and the low nickel content are not balanced to form ferrite. For this reason, the chromium content in the 200 series stainless steel is reduced to 15% to 16%, and in some cases, It is reduced to 13% to 14%, and its corrosion resistance is not comparable to that of 304 and other similar steels. Also, under the acidic conditions common in the corrosion parts of the deposition area and crevices, manganese and in some cases copper is reduced and then passivated.

The role of chemistry. The destruction rate of 200 series steel under these conditions is about 10-100 times that of 304 stainless steel. Also, it is often impossible to control the residual sulfur and carbon content in these steels during production, and the materials cannot be traced back to the source, even in the recycling of materials. If Cr-Mn steel is not specified, it will become a dangerous mixed raw material for scrap steel, resulting in unexpectedly high manganese content in castings.

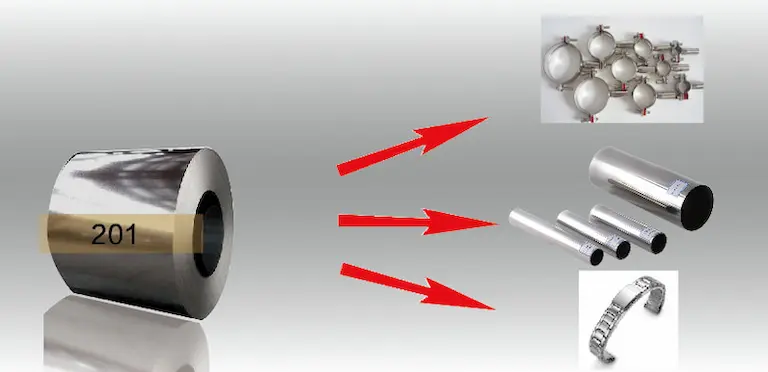

201 stainless steel has the characteristics of acid and alkali resistance, high density, no bubbles, no pinholes, etc. It is used to produce high-quality materials for various watch cases and watchband back covers. Mainly used to make decorative tubes, industrial tubes, and some shallow stretched products.

There are three types of cheapest stainless steel on the market: 201, 409, 410 stainless steel.

As one of the cheapest kind of stainless steel, the 201 ss chromium content is 16-18, and the nickel content is only between 0.3 and 1.2. There are also many 201 rolled plates on the market, and the price is relatively cheaper. 201 is more used in kitchen equipment, and tableware is rarely used. The surface of 201 is a bit worse than that of 304, and its stamping performance is also worse.

409 stainless steel is universal chromium, titanium stabilized du ferritic stainless steel, and its main application is the automobile exhaust system. Contains 11% chromium, which is the minimum amount to form a passive surface film for corrosion resistance of stainless steel. It has good high-temperature corrosion resistance, medium strength, good formability, and overall cost. Compared with carbon steel, 409 alloy has strong corrosion resistance and can be used as a substitute material for carbon steel in a mildly corrosive environment. Because of its higher corrosion resistance and high-temperature oxidation, it has advantages. Usually used in applications where appearance is a secondary quality of mechanical properties and corrosion resistance.

410 stainless steel contains 0.15% carbon, 13% chromium, C≤0.15, Si≤1.00, Mn≤1.00, P≤0.035, S≤0.030, Cr=11.50~13.50. 410 stainless steel has good corrosion resistance and machinability, General purpose blades, valves, mechanical parts, class 1 tableware (spoon, fork, knife, etc.).410 stainless steel has high strength; excellent machinability, hardened after heat treatment; magnetic; not suitable for harsh corrosive environments.

BEST 304 Stainless Steel Products in China

201 stainless steel will rust under certain conditions. For example, it will rust when placed in saltwater. Yayoi is equipped with a salt spray tester. In addition, it can test how long it will take to rust 201 stainless steel sprayed with saltwater or human hand sweat. But it is not easy to rust in a daily environment.

Because of nickel, stainless steel is not easy to rust. With less nickel contains , 201 stainless steel is easier to rust than 304 stainless steel.

Stainless Steel 316 And 316L Graded By The AISI System

The composition of high-quality 201 stainless steel is uniform, the tonnage of cold shear is high, and the end surface of the cutting head is smooth and neat. However, due to the poor material of the fake, the end surface of the stainless steel cutting head is usually uneven and has no metallic luster.

The cross section of defective 201 stainless steel strip is oval. Due to saving materials, the manufacturer often reduce the first two passes of finish roll. The strength of this steel is greatly reduced, and it does not meet the size and standards.

The inferior 201 single steel strip contains many impurities, on the other hand, the density of the steel is small, and the size is seriously out of tolerance. Above all, it can be weighed and inspected without a vernier caliper.

201 stainless steel products are characterized by acid resistance, alkali resistance, high density, no bubbles, no pinholes, etc., which are very suitable for the production of various watch cases and watch band back covers. It is also widely used in some shallow stretch products on decorative tubes and industrial tubes.

To ensure the delivery of your products, Yaoyi stainless steel foil manufacturer use a specially customized production management ERP system. Whether you need stainless steel foil for trading companies or traditional factories, Yaoyi provide solutions. Similarly, with the MOQ, you can get a sufficient quantity of stainless steel foil for sale or production.

After years hard working, Yaoyi is well-known of excellent stainless steel foil production. Our well-trained and experienced engineers ensure the production of high-quality stainless steel foil. Combined with our quality management system, you can find the high quality & suitable price stainless steel foil for your business.

Our fast delivery time and excellent service make us one of the most reliable stainless steel foil manufacturers in China. We can help you making your business grow rapidly in the market and any platform where you want to show your brand.

201 Stainless Steel exhibits good corrosion resistance compared to other types of steel. It is particularly resistant to a variety of oxidizing environments. However, it’s less resistant to corrosive conditions such as saltwater or environments with high chloride concentration.

At room temperature, 201 Stainless Steel displays excellent mechanical properties. It has high tensile strength and a high yield strength, making it robust and durable. It also has good elongation properties, meaning it can be stretched or formed without breaking.

Stainless Steel, including 201 grade, is often used in government infrastructure projects due to its high strength, durability, and corrosion resistance. However, the cost can be a drawback, as it is often more expensive than other materials. The sustainability of stainless steel is another advantage, as it is 100% recyclable.

ASTM provides standards for 201 Stainless Steel in various forms. For instance, ASTM A666 covers annealed or cold-worked austenitic stainless steel sheet, strip, plate, and flat bar. The finishes for 201 Stainless Steel can range from a bright, reflective finish to a dull, matte finish, depending on the application.

201 Stainless Steel is highly versatile for outdoor parts. Its high corrosion resistance makes it ideal for outdoor applications, even in harsh weather conditions. It’s also a great choice for parts that require complex shapes and forms due to its excellent formability.

201 Stainless Steel is particularly useful in the automotive and construction industries due to its strength and corrosion resistance. In automotive applications, it is used in various components, including exhaust systems. In construction, it is used for structural components and decorative elements.

201 Stainless Steel is often chosen for government infrastructure projects due to its high corrosion resistance. Even when exposed to harsh weather conditions, it can maintain its integrity for a long time, making it a cost-effective choice for public works projects.

201 Stainless Steel can be found in various hardness levels, from soft and half-hard to full hard and extra hard. The hardness level is determined by the amount of cold working the material has undergone.

201 Stainless Steel is known for its excellent formability, which means it can be easily shaped and formed into various components without breaking or cracking. This property makes it highly suitable for applications that require complex shapes and designs.

In terms of weldability, 201 Stainless Steel is considered to have good weldability. It can be welded using conventional welding techniques, such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance welding. However, it is important to use low heat input and interpass temperatures to avoid hot cracking and maintain corrosion resistance.

There are several advantages of using 201 Stainless Steel in automotive and construction industries:

High strength: 201 Stainless Steel has a high tensile and yield strength, making it suitable for applications that require durable and robust materials.

Corrosion resistance: It offers excellent corrosion resistance, especially in oxidizing environments. This property makes it suitable for outdoor applications and exposure to harsh weather conditions.

Formability: 201 Stainless Steel is highly formable, allowing for complex shapes and designs in components used in both automotive and construction industries.

Weldability: It is easy to weld using various welding techniques, making it a versatile material for assembling components.

Cost-effectiveness: 201 Stainless Steel is more affordable compared to other stainless steel grades, making it a budget-friendly option for large-scale projects.

The physical properties of 201 Stainless Steel vary with temperature. As the temperature increases, its strength decreases, but its ductility improves. Additionally, the coefficient of thermal expansion and thermal conductivity change with temperature. It’s crucial to consider these factors when designing components for high-temperature applications.

When processing and forming 201 Stainless Steel, it is essential to consider the material’s mechanical properties and the final application. This material can be cold worked to increase its strength and hardness, but this process may reduce its formability. Annealing can be used to improve the formability and relieve internal stresses after cold working. When forming 201 Stainless Steel, it’s crucial to consider the material’s ductility and plan for any potential spring-back to ensure the desired final shape.

Grade 201 Stainless Steel is a smart choice for various applications due to its combination of high strength, corrosion resistance, formability, and weldability. Additionally, its cost-effectiveness makes it an attractive option for large-scale projects in automotive, construction, and infrastructure industries.