In Myriad, there are several corrosion features of AISI 301 Stainless Steel Properties, including being non-corrosive, rust-resistant steel, and steel that is merely designated as stainless steel, among others. Stainless steel is approximately three times heavier than aluminum when compared to the latter.

Like steel in general, the stainless steel AISI 301 is an element alloy. A series of different components is always made up of an alloy. Chrome is one of the most often used alloys in non-corrosive stainless steel that is also utilized for unique applications in non-corrosive stainless steel with nickel, molicobene and other elements.

Two of these needs, namely magnetisability and corrosion resistance, are controlled by the different alloys used in their production.

Myriad’s aisi 301 stainless steel is steel that contains more than 10.5 percent chromium, as well as many other elements in lower amounts, and is therefore regarded to be corrosion resistant.

When combined with oxygen, chromium generates a thin, sealed, fixed-adhering chromic-oxide layer – the so-called passive layer – that is impervious to light and heat. It is precisely this passive layer that is responsible for the material’s resilience to abrasion. Because of its corrosion resistance, the metal is employed in a variety of applications such as washing drums.

Myriad’s corrosion-resistant aisi 301 stainless steel can be very closely compared to the anodized aluminum in terms of its physical and mechanical properties. When the outer skin of a material is compromised, the substance and its surface bear the majority of the consequences.

ASTM A167: Composition, Properties, and Equivalent Grades

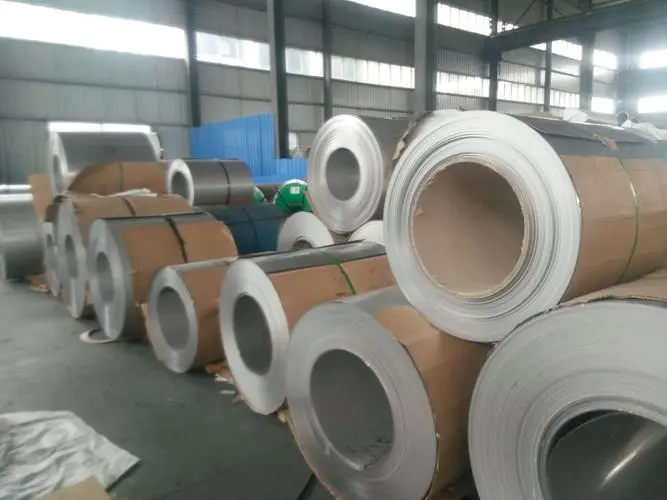

You can get the more cost-effective 301 stainless steel material from Yaoyi. Thickness 0.1 mm~0.3 mm, width 550-600 mm cold rolled stainless steel coil.

If your confusion over the significance of the above traits lies in our overview of material properties, you can refer to each one for a more detailed explanation.

Depending on the grade, inoxidable steel can either have high strength and low elongation or low strength and high elongation. They do wonderfully in comparison to carbon steels when it comes to yield strength.

When confronted to high temperatures, the performance of Yaoyi’s aisi 301 is comparable to other carbon steel qualities. Due to its strong strength retention factor at high temperatures (above 500 °C) it has greater fire resistance to other materials. Furthermore, when heated above 300°C, it also has a higher rigidity retention than carbon steel.

In addition, aluminum, brass, and mild steel are all inferior to aisi 301 stainless steel when it comes to tensile strength; stainless steel is superior to all of these materials.

Moreover, precipitation hardening and martensitic grades have the maximum tensile strength, followed by brittle grades. It is possible for these grades to have tensile strengths that are two times greater than the commonly used 304 and 316 steels. The strength-to-ductility ratio of duplex steel, in particular, is very high.

A Manufacturer of Stainless Steel Strips

There are several Yaoyi aisi 301 EDS characteristics that can resist a broader temperature range remarkably. Subzero temperatures show exceptional toughness as well as increased resistance to tensile austenitic stones. This substantially expands the application area and offers whole new avenues for modern apps.

On the other hand, hardening grades of ferrite, martensitic and precipitation at cryogenic temperatures are not that good as their tightness slows down when the temperature drops below a specific threshold.

A large difference might exist between different stainless steel grades when it comes to ductility. Some grades have a high degree of ductility, which allows them to be used in demanding deep drawing procedures.

When a metal can be made stronger through cold working, it is said to have a high strength-to-weight ratio. Anodizing and cold working stainless steels allow you to control the strength of the steel to the level you wish.

Therefore, this means that the same grade can be utilized in a variety of applications by altering the strength of the material. For example, by annealing and cold working the same grade of steel, it can be utilized as a spring or bendable wire, among other applications.

AISI 301 stainless steel properties conduct electricity in the same way that all metals do. Although this conductivity is exceedingly low in comparison to other steels, it is present in all steels.

In companies that have stringent hygiene standards or that have electrical devices subject, such as corrosive or humid environments, Yaoyi’s aisi 301 stainless steel features boxes are utilized to protect electrical appliances.

Note that although austenitic stainless steels are not magnetic, cold working is used in certain types of austenitic stainless steel, for generating magnetic features. All other types also possess magnetic properties.

What is Stainless Steel Strapping?

The chemical features of this material are what distinguish it from other materials and give it its distinctiveness:

This distinguishing quality of Yaoyi’s aisi 301 stainless steel properties is responsible for the wide range of unique applications that it has in the industrial sector. The presence of chromium in stainless steel contributes to its excellent oxidation resistance. In some grades, the amount of chromium can reach as much as 26 percent by weight.

Coats and anti-corrosion paints can save other metals, but the corrosion process begins anew as the protection wears down. Due to surface damage, a natural chromium oxide coating in stainless steel can be removed and a fresh coat is created on the exposed surface that prevents the corrosion from becoming worse.

It is a great biological inertness for health equipment such as surgical instruments, trauma screws and plates because of stainless steel. It is a good metal that may be used, among other things, in cutlery and culinary appliances.

Acid, base, and organic compounds are not a problem for this substance.

Myriad’s stainless steel aisi 301 also has a wide range of chemical resistances. Among other things it is resistant to acids, foundations and organic chemicals. Acid resistance varies depending on the level of application. Some grades can survive very concentrated acids, while others can withstand just minor amounts.

Basic compounds and organic compounds are comparable to those of basic compounds, and both show no reactivity. In this respect, stainless steel is an incredibly excellent material for a number of applications, including storage, handling and other procedures, in the chemical sector.

Myriad’s 301 stainless steel properties are also extremely resistant to moisture, salt, sulphur, carbon dioxide, and chloride-containing chemicals. This allows it to endure in a variety of severe settings for a longer period of time than the majority of other metals.

Myriad manufactures unique pressure vessel connections made of high-quality stainless steel. AISI 301 stainless steel properties possess a number of characteristics that make it an excellent material for forging ASME pressure vessel connectors projects, among them.

Tensile strength is a measure of a material’s resistance to breaking when subjected to tension. The tensile strength of Yaoyi’s aisi 301 stainless steel properties is stronger than that of mild steel and other materials such as aluminum in most cases, including martensitic and precipitation hardening grades. Work hardenability is a property of several varieties of stainless steel, which means that they may be strengthened to a specified tensile strength by a combination of cold working and annealing processes.

Ductility is renowned for the capacity of the material to stretch under pressure. Various forms of stainless steel, and for many of their derivatives, are exceedingly ductile. Austenitic aisi 301 is highly ductile with elongation values in certain cases exceeding 50 per cent. In order to achieve the optimum balance between strength and ductility, cold working can be used to achieve the AISI 301 stainless Steel characteristics.

The element chromium is used to form a protective, self-healing oxide coating on the surface of Yaoyi’s aisi 301 stainless steel properties. All forms of stainless steel are made corrosion resistant by the presence of this protective layer. A cut, scratch, or other type of damage to the surface will not affect its ability to self-heal and preserve its corrosion resistance. The surface of mild steels can be protected against corrosion by coatings or paint, but any surface damage will render the material vulnerable.

Stainless Steel Chemical Composition

AISI 301 stainless steel, unlike mild steel, does not degrade when exposed to high temperatures. It can withstand temperatures of up to 1100 degrees Celsius and still remain strong and durable. Yaoyi’s is also capable of retaining its ductility and hardness at temperatures below zero degrees Celsius. Stainless steel varieties such as austenitic stainless steel can be used at temperatures as low as -196 degrees Celsius.

Myriad’s aisi 301 stainless steel was utilized first to create its prototype automobiles in the automobile business. Since then, a range of automotive components including exhaust systems, grids and car parts have been manufactured. With technological progress, the building of structural components is increasingly turned to stainless steel.

Also, it is commonly utilized as a freight for the production of cargo containers, road tankers and garbage collection trucks in various modes of transport. It is a great choice for the transport of chemicals, liquids and food products because of its resistance to corrosion. Because of low care requirements for stainless steel, cleaning and maintaining it in excellent condition is a simple and cost-effective metal.

Myriad’s aisi 301 stainless steel is used in clean and sanitary environments because it is easy to clean and not as easy to corrode as other metals. In the medical sector, stainless steel is used to produce a variety of medical equipment, including operating and dental instruments.

They are also used in the building of operating tables, kidney plates, MRI scanning devices, cannulas and steam sterilizers, to name a few.

In the production of most surgical implants, such replacement joints and artificial hips, Yaoyi’s aisi 301 is employed for stainless steel qualities. In the fabrication of various joining systems, such as stainless steel pins and sheets used for treatment of injured bones, steel is also used.

Because of Myriad’s aisi 301 stainless steel properties, strength, resilience, and flexibility, stainless steel application has emerged as a critical component of the construction industry’s arsenal. It is often utilized in the interior on worktops, backsplashes, and handrails, and it is also employed externally in the cladding of high-impact buildings to protect them from the elements.

It is a common aspect of modern architecture due to its weldability, easy maintenance, and attractive finish. It is present in locations such as London’s Eurostar Terminal and Singapore’s Helix Bridge, among others.

Myriad’s aisi 301 stainless steel properties, which is a highly recyclable metal, is becoming increasingly popular for use in construction as the building industry moves toward more environmentally friendly practices. It has aesthetically pleasant features, especially when finished in a polished or grainy manner, and it can help to improve natural illumination in a building.

A desire for stainless steel is also expressed by the aviation sector. It is utilized in a variety of applications, including the frames of airplanes, because of its strength and capacity to tolerate high temperatures in severe environments. It can also be used in jet engines to assist prevent rusting because it has anti-corrosion properties.

Stainless steel is also used extensively in the construction of the landing gear. This structure’s strength and stiffness are sufficient to support the weight of the landing aircraft.

Is 301 Stainless Steel Magnetic?

AISI 301 stainless steel is used in the food and catering business to create kitchen equipment, cookware, and cutlery, among other things. Knives and other kitchen utensils are constructed from stainless steel that is less ductile in nature. Grills, cookers, saucepans, and sinks are all made from the more ductile varieties of stainless steel.

A coating formed from aisi 301 can therefore be used in a number of devices such as freezers, washing machines, refrigerators and countertops. Aisi 301 can therefore be applied. Steel is the material of choice for the production of foodstuffs, because the taste of the meal does not change.

Aside from that, it is corrosion resistant, making it suitable for holding acidic beverages such as orange juice. The simplicity with which stainless steel can be cleaned makes it impossible for bacteria to grow, which increases its value in food storage.

Grade 304 Stainless Steel Foil

Myriad’s aisi 301 stainless steel (UNS S30100) is the most sensitive of all regularly used austenitic stainless steels to reinforce cold deformation. Due to its extraordinarily fast work hardening rate, the tensile strength and the output strength will grow rapidly as cold work on the material increases.

The response to work hardening is particularly important for structural items such as angle steel and channel sections since they are expected to increase in strength and stiffness after manufacturing. On the other hand, deep drawings normally require a lower hardness rate than is possible in common drawing applications, with a bigger nickel concentration in austenitic alloys (especially types 304, 304L, and 305).

When exposed to atmospheric circumstances, the qualities of Yaoyi’s aisi 301 stainless steel are suitable for corrosion; yet, it is not good for use in harsh corrosion settings, but also for chemical substances such as acids, alkalis and saints. The system is used to support greater loads mainly in a cold working condition, but the weight of equipment and corrosion-resistant components is also expected to be reduced by employing it in a hot working environment.

ASTM A167: Composition, Properties, and Equivalent Grades

AISI 301 stainless steel is an austenitic stainless steel alloy that displays excellent corrosion resistance and has a high strength-to-weight ratio. It’s commonly used in spring applications due to its excellent fatigue resistance. Furthermore, it can withstand moderate to high temperatures, making it versatile across many industries, including automotive, aerospace, and oil & gas.

AISI 301 stainless steel, also known as 1.4310 spring steel, possesses exceptional mechanical properties that make it ideal for spring applications. It has high yield strength and hardness, which can be further increased through cold working. This allows it to handle a large amount of stress, making it suitable for springs that need to retain their shape and strength after repeated use.

The density of 301 stainless steel is approximately 7.88 g/cm3. This property is important when considering the weight and volume of a component. Although this might not seem like a significant factor, it can influence the efficiency, performance, and overall costs of a project, especially in industries where weight is a critical parameter.

301 stainless steel has a yield strength of around 215 MPa in the annealed condition. However, this value can significantly increase through cold working, allowing the material to withstand more stress before deformation. This is a crucial property when designing components that will face substantial stress or tension, such as springs or automotive parts.

AISI 301 stainless steel, also known under UNS S30100, has a chemical composition that includes Chromium (16 – 18%), Nickel (6 – 8%), Silicon (up to 1%), Manganese (up to 2%), Carbon (up to 0.15%), and balance Iron. This blend of elements contributes to its overall strength, corrosion resistance, and formability.

The hardness of AISI 301 stainless steel is typically around 185 Brinell in the annealed state. However, by applying cold work to the material, this value can be significantly increased. The hardness of stainless steel is important because it directly correlates to the material’s resistance to deformation, indentation, or scratching. A higher hardness value indicates a more rigid and robust material.

Yes, AISI 301 stainless steel is somewhat magnetic. While most austenitic stainless steels are considered non-magnetic, 301 stainless steel can become magnetic when cold worked. This magnetism is not as strong as that found in ferritic or martensitic stainless steels, but it can still be detected with a basic magnet. This magnetic property can be crucial in some applications, particularly in electronics or where magnetic fields are present.

X10CrNi18-8 is the EN numeric designation for AISI 301 stainless steel. This material is typically used in applications that demand high strength and good corrosion resistance. X10CrNi18-8 is most often seen in spring applications, railcar components, and other industrial parts.

X10CrNi18-8, otherwise known as AISI 301 or 1.4310, has equivalents in different standards. For example, in the UNS system, it is known as S30100. However, it’s important to note that while materials may be equivalent or similar in one or more properties, they may not be identical in all aspects, as each standard takes different factors into account.

1.4310 is the EN numeric designation for AISI 301 stainless steel. The material specification for 1.4310 highlights its notable attributes, such as high strength and corrosion resistance, along with its unique mechanical properties. It’s crucial to understand the exact specification of 1.4310 to ensure that it’s the right material for your project.

AISI 301 stainless steel is equivalent to EN 1.4310, UNS S30100, and JIS SUS 301. These are the equivalent designations in the European, Unified Numbering System, and Japanese steel grades, respectively. While these grades are equivalent, slight differences may exist due to local standards and specifications.

Stainless steel 1.4310 is equivalent to AISI 301, UNS S30100, and JIS SUS 301. It’s important to understand that even though these materials are considered equivalent, slight variations in their properties might occur due to regional differences in standards and production practices.

Please note that these are general answers and may not account for specific project requirements or nuanced technical details. Always consult with a materials expert or trusted supplier when making decisions about material selection.