A Complete Guide to 316L Stainless steel

As a leading manufacturer, yaoyi provides customized 316L stainless steel with affordable prices and high-quality services to meet your requirements. As we all know, the production of 316L SS must undergo strict production control and quality inspection. Through advanced technology manufacturing, Yaoyi can provide the best solutions for various 316L stainless steel needs.

Over the past 25 years, as an engineer, the founder has accumulated rich production experience and always pursues the highest quality. This means that Myriad can provide you with the best and most reliable 316L stainless steel in China.

Thanks to flexible production management, even in peak seasons, we can complete orders within the specified delivery time.

Get BEST 316L Stainless Steel Products From China

Myriad provides you with high-quality 316L stainless steel service. 1/2 hard is the hardness range that Mriad is best at. You can rely on us and we will provide you with reliable stainless steel raw materials.

304 Stainless Steel Coil

301 Stainless Steel Coil

316 Stainless Steel Coil

316L Stainless Steel Coil

Material Testing After You Place An Stainless Steel Foil Order

Hardness Testing

Ingredient detection

Tensile Strength Test

Table of Contents

Why is Mriad a trusted manufacturer of 316L?

Myriad is a professional manufacturer specializing in the production of aisi 316L material.

We are committed to manufacturing high-end and world-class stainless steel products.

All our 316L are made of high-quality hot-rolled materials.

We are always providing you with higher quality products at reasonable prices.

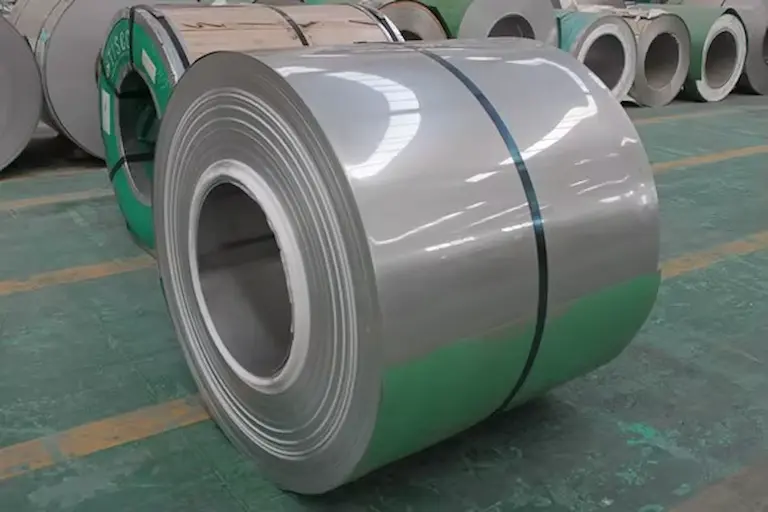

316L stainless steel coil

316L SS coil is made of high-quality 316L hot rolled coil. It has high-quality corrosion resistance. Myriad has produced in strict accordance with ASTM standards, and the content of Ni is 10~14%. So we can provide reliable 316L stainless steel coil from China.

316L stainless steel foil

At the same time, we are a certified manufacturer, in terms of service production, you can trust Mriad. If you are looking for 316L stainless steel foil, you can tell us your hardness requirements, even if the order is small, we will provide you with full service. Because at Myriad, we always put the quality requirements of each user in the first place.

Myriad’s stainless steel products

Myriad is a professional manufacturer of 316L stainless steel in China. We have extensive experience in the industry. Therefore, we are able to understand the needs and requirements of our customers. Also, we are committed to providing you with the best stainless steel solutions based on your needs and applications, with a professional team of steel engineers.

Moreover, as a professional manufacturer, the 316L SS we provide is widely used in high temperature and high acid working environments. We use complete and advanced production lines to produce 316L stainless steel. The aisi 316L stainless steel we produce is strictly monitored by our professional quality control at every stage of production. Each batch of products produced and shipped is kept in the laboratory for 3 years to ensure stable quality. Therefore, you can ensure that yaoyi provides high quality and cost-effective 316L stainless steel.

Besides, 316L stainless steel has high-quality stability in a strong acid and strong alkali environment, and is widely used in the production of material accessories in this environment.

In conclusion, Yaoyi’s professional stainless steel production R&D team will cooperate with you, so we can produce raw materials for you according to your hardness and specifications. Yaoyi will also provide you with reasonable prices without compromising quality. Yaoyi is undoubtedly a one-stop stainless steel solution to meet your business or project needs!

316L stainless steel tube

If you are looking for a reliable 316L stainless steel tube manufacturer, Yaoyi is one of the best manufacturers. We cooperate with 24 stainless steel tube factories to form an industrial alliance to provide you with industrial-grade 316L stainless steel tubes such as round tubes, square tubes, and special-shaped tubes.

316L stainless steel sheet

Yaoyi provides you with high-quality 316L stainless steel sheet with 2B and BA surface. We can provide you with customized size service according to your order. You can tell us your product requirements according to your production requirements, and we have a professional team of engineers to serve you.

The 316L Stainless Steel Grade

Grade 316L stainless steel is characterized by high corrosion resistance. This property is accredited to its high molybdenum and nickel content. The stainless steel grades are categorized based on variations of elemental compositions. Similarly, subgrades were made from these ‘major’ grades to emphasize features desired while maintaining many general properties.

In grade 316, it has subgrades categorized as L, F, N, and H variants. These subgrades are slightly similar and different from one another, each made to fit various applications. This article will be discussing one of these subgrades, in particular, the 316L stainless steel subgrade.

SUS 301 Stainless Steel: The Ultimate Guide

What Does 316L SS Mean?

316L SS (stainless steel) stands for two types of distinction. First, 316 represents the ‘primary’ stainless steel grade 316, while L stands for a variant within this grade. L stands for “low carbon,” which, as the term implies, represents a variant of grade 316 with low carbon.

How To Identify 316L SS(Properties)?

Grade 316 and 316L share almost all the same properties except those affected by carbon. Carbon is generally the most critical element in creating steel. Higher carbon content equates to higher strength, hardness, and better properties in tempering or hardening. However, excessive carbon content can also cause the steel to become brittle and susceptible to carbide precipitation.

Categorizing 316L is impossible to do using only the naked eye. Its uniqueness underlies within the properties it exhibits. Thus, we enumerated below these respective properties, which will help you identify a grade 316L stainless steel.

Your Best Supplier Of Stainless Steel Coil Always Provide You With SS Coil From China

1. Internal Crystalline Structure

316L shares the same austenitic structure that grade 316 has. These austenitic structures make steel incapable of hardening using heat treatment. Usually, manufacturers make these steel types in annealed form. Furthermore, this type exhibits good workability, which can be drawn or cold rolled easily.

2. High Corrosion Resistive Elemental Content

Grade 316L is an austenitic chromium-nickel steel that has around 2-3% molybdenum. This molybdenum content is a distinctive characteristic of any variant emerging for the primary 316 grade. The molybdenum content is the chemical responsible for the high corrosion resistance the grade has.

As aforementioned, 316L only differs from 316 by the amount of carbon it has. It has only a 3% maximum carbon content than the higher 8% maximum the regular grade 316 has. This carbon content difference is what allows grade 316L to be more resistant to carbide precipitation when welding.

3. Physical Properties

Grade 316L is denser than 316. It has 8.027 g/cm³ of density compared to 7.98 g/cm3 that 316 has. Similarly, it exhibits a higher melting range of 2540-2630°F, which is 40-80°F than 316. Furthermore, it has an elastic modulus of 200 GPa and a shear modulus of 82 GPa. As for the electric resistivity, it has the same 740 nΩ.m. of resistance as 316.

These properties are the necessary thresholds to identify in subjecting 316 on specific physical strains. For example, you can use the melting range as a reference for applications requiring intense heat.

Stainless Steel Foil Manufacturer

4. Mechanical Properties

Grade 316L having lower contents of carbon meant lower tensile and yield strength. This L variant shows a lower tensile strength of 485 MPa compared to 515 MPa 316 has. Furthermore, 316L only has a yield strength of 170 MPa versus the 205 MPa of grade 316. As for elongation and Rockwell hardness, it exhibits the same 40 and 95 scales that grade 316 has, respectively.

In these mechanical properties, you can find a lower carbon content with adverse effects. Carbon is used to regulate steel strength and hardness. Thus lower carbon contents also reduce the steel strength thresholds.

5. Weldability

Grade 316L having lower carbon content reduces the risks of carbide precipitation. Carbide precipitation happens when carbon reacts to chromium due to high welding heat. As a result, this reaction weakens the corrosion resistance of the stainless steel. Therefore, this characteristic makes 316L ideal for applications involving extensive welding operations.

All of the properties above are just some of the many identifying characteristics grade 316L stainless steel has. Further tabulations and specifications can be obtained from your local manufacturers or standards from regulating bodies. Be sure to check those out if you need a more in-depth presentation of its chemical composition and properties.

Always Provides You with the BEST Austenitic Stainless Steel Products

What is the Difference Between 316 and 316L?

Although 316L shares many properties as the regular 316 has, there are still differences that suit different applications. It is important to emphasize their contrasts to know which one is to use for particular requirements. Below we further discuss their differences in properties and application:

316 Stainless Steel

316 Stainless steel grade has more carbon than 316L. It contains around 8% maximum carbon content. This carbon content is a double-edged sword that has both pros and cons to consider. Enumerated below are the features 316 exhibits:

- Has high corrosion-resistance

- High carbon content can cause carbide precipitation or weld decay while welding.

- Retains relatively higher tensile and yields strength than 316L.

These features of grade 316 allow it to be used on applications needing high corrosion resistance. However, it might entail certain precautions if it needs to be welded. Higher carbon contents are susceptible to carbide precipitation which is harmful to the steel’s corrosion resistance.

In contrast, having higher carbon content makes it exhibit better mechanical properties, which will benefit structural applications. Below are some of the most suitable applications of grade 316 stainless steel:

- Marine applications

- Aerospace

- Food processing

- Coastal architecture finishes

Difference Between AISI 304 and AISI 316

316L Stainless Steel

On the other hand, grade 316L has a lesser carbon content of 3% maximum in its chemical composition. This composition minimizes the risk entailed by higher carbon content. However, reducing carbon also caused adverse effects on a few of its properties. Below are the characteristics the 316L subgrade exhibits:

- Lower carbon

- A better option for welding avoiding carbide precipitation

- Exhibits higher temperature thresholds

- High corrosion resistant

- Relatively lower tensile and yield strength than 316 because of reduced carbon content.

Lower carbon made 316L a more viable option for welding because it minimizes risks for carbide precipitation. Furthermore, it also has a higher temperature threshold beneficial for chemical processing. However, lower mechanical properties limit its structural applications. Below are some of the best applications of grade 316L:

- Chemical and petroleum industries

- Chemical piping

- Food processing

- Pharmaceutical equipment and medical devices

- Marine or coastal applications.

- Potable water piping

- Furnace components and heat exchangers

- Body piercings

Which is Better?

There is really no better or worse variant between grades 316 and 316L. Their forte relies on a specific niche that concerns their varying carbon content. That is why a user needs to fully understand an application to ensure they invest well in that niche.

From a layman’s point of view, a clear distinctive line between these two grades is blurred. Indeed, their application can overlap because of their almost similar properties. Generally, any subgrade below 316 can be used for applications that need corrosion resistance because of its molybdenum content.

However, if your application requires a lot of welding processes, then 316L shall be more suitable. The higher heat resistance also complements these grades’ reliability with the former. Notably, this grade excels in chemical piping applications, where many steel components need to be adjoined using welding.

Furthermore, many surgical implants and prostheses are made of this grade because they are less brittle and more corrosion resistant. You may always consult your local manufacturers and professionals for a more detailed explanation of this grade’s application.

Is 316L SS Food Grade?

316L stainless steel is among the stainless steel grades used for food processing.

Its high chemical resistance and temperature threshold make it a desirable material for the food-related application. Furthermore, in comparison with the most common 304 grade, 316L performs better in chloride pitting and corrosion in general.

Stainless Steel AISI 316Ti (S31635) By The AISI System

Is 316L SS Expensive?

In comparison, grade 316L is more expensive than most common stainless steel grades such as 304. However, if we are comparing 316L versus the other 316 variants, prices are almost the same. Grade 316 stainless steel is generally more expensive than 304 because of its molybdenum content. Molybdenum is a costly element that you can add to stainless steel to boost its corrosion resistance.

Thus, this makes it essential that 316L fits your application before purchasing. Otherwise, you might be spending money on properties you might not need. On the other hand, also be mindful of using different steel grades where on applications 316L excels at.

What is J4 Stainless Steel? (And What Is It Used For)

Conclusion

Generally, one should understand both the material and its application to make an efficient use. This is more relevant to subgrades such as 316L SS.

Grade 316L is a stainless steel subgrade with a specific niche which is its weldability and heat resistance. Be sure to understand the material and application to maximize its potential.

Of course, the quality of materials also depends upon the competence of your manufacturers. If you ever need assistance with or a supplier of grade 316L stainless steel, please feel free to contact us.

Yaoyi takes pride in delivering only top-quality services and steel products.

J3 Stainless Steel : A Complete Guide For Importers