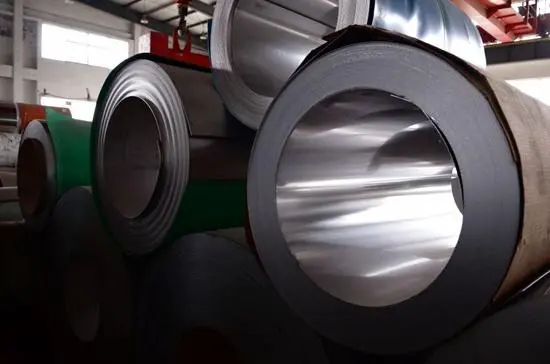

AISI 303 stainless steel coil is a widely popular type of alloy used to make various products, including kitchenware and machinery. Not only is it affordable, but it’s also rustproof, corrosion-resistant, and heat-resistant. It can also be purchased as sheets, bars, and plates, making it ideal for different applications.

Depending on what you’re using stainless steel for, there are different grades that you can look into. And chances are you can find them all in Myriad product catalog. They are the leading industry that has been manufacturing stainless steels for over 25 years.

There are about 150 stainless steel grades, 15 of which are the most commonly used. These include the 304 and the 316, which are part of the 300 series, the largest and most popular. But, we’ll be talking about the AISI 303 stainless steel grade.

AISI is an abbreviation for the American Iron and Steel Institute, an association of steel producers in North America. It’s widely known for promoting the steel industry and for maintaining the numbering system for stainless steel. The AISI categorized stainless steel into different groups: 200, 300, and 400 series. Generally, the 200 and 300 series are austenitic, while the 400 series is composed of ferritic and martensitic stainless steel.

The AISI 303 stainless steel is part of the 300 series, austenitic stainless steel family. 303 is a numerical representation of its grade, allowing users to identify its various applications and properties.

Generally, the AISI 303 is known for its strength and machinability, making it an ideal material for free machining. Besides this, the 303 also stands for the added Sulfur or selenium. Because of this, the AISI 303 is less corrosion-resistant but is more machineable. It was also developed for easy cutting, which reduces its resistance to cutting equipment.

The best method to identify a stainless steel grade is by inspecting its composition. Different stainless steel grades are developed differently, which allows you to classify them. This way, you can find the proper specifications for the steel you’re going to use. Below are the unique characteristics of the AISI 303 to help you determine if it’s the grade you’re looking for.

The AISI 303 stainless steel is austenitic. This means that it’s non-magnetic and is hardenable through cold working. However, the 303 is not readily cold-workable due to its added Sulfur.

While all austenitic stainless steel types are resistant to corrosion, the levels vary depending on their chemical composition. Because of the added Sulfur, 303 stainless steel stainless steel has less corrosion resistance compared to other alloys. However, while this is the case, 303 stainless steel is highly corrosion-resistant in different environments. These include atmospheric sources, organic chemicals, dyes, and sterilizers.

In addition, 303 stainless steel also resists nitric acid. On the other hand, it isn’t corrosion-resistant to environments that are rich in Sulphuric acid and halogen acid. If you need the optimal corrosion resistance of the 303 stainless steel, it should be cleaned and passivated thoroughly after machining. This way, you can remove oil, grease, and other foreign substances from the material.

Aside from this, the 303 stainless steel is also oxidation-resistance at temperatures up to 760°C. Its oxidation resistance is also good in continuous service at temperatures of up to 870°C. However, we do not recommend this because 303 stainless steel is sensitive to carbide precipitation at temperatures ranging from 425-860°C.

AISI 303 has a density of 8.03 g/cm3. Due to this, it’s denser than other grades. Moreover, it has a high melting point of 1455°C, making it highly heat-resistant. Its modulus of elasticity is 193 GPa, and its resistivity to electricity is 0.072×10-6 Ω.m. Similarly, its thermal conductivity is 16.3 W/m.K and thermal expansion is 17.3×10-6 /K, both at 100°C.

While most stainless steel grades contain around 10% of Chromium, the AISI 303 contains approximately 17% to 19%. It also has a Carbon content of 0.15% and a Silicon content of 1.00%. Additionally, this grade has 2.00% of Manganese, 0.20% of Phosphorus, 0.15% of Sulfur. Lastly, it’s also composed of Nickel, which ranges from 8.00% to 10.00%.

As mentioned, the AISI 303 stainless steel is ideal for machinability. This is because of its mechanical properties. It has a tensile strength of 500 MPa, making it resistant to certain levels of tension. It also has proof stress of 190 MPa and an elongation of 35%. Additionally, it has a Hardness Rockwell level of a maximum of 262 HB.

While the 303 stainless steel is ideal for machining, it doesn’t work well when welding due to added Sulfur. However, if welding is unavoidable, it must be fused with filler rods, with recommended 308L and 309. Additionally, if maximum corrosion resistance is desired, the welds should be annealed.

As mentioned earlier, the AISI 303 is not readily cold-workable due to its high sulfur content. However, you can use a high bend radius for this stainless steel grade. Similarly, the 303 stainless steel is not ideal for a hot working environment because of its high sulfur content.

In addition, you should use a temperature range of 982°C to 1204°C if forging is needed. It should also be annealed at a minimum of 1037°C followed by rapid cooling.

You cannot harden the AISI 303 by heat treatment. However, you can use solution treatment or annealing at temperatures ranging from 1010°C to 1120°C.

How to Remove The Oxide Scale on The Surface of Stainless Steel Casting Billet?

People use it to make products that require heavy machining. Commonly, the AISI 303 is used to make small components, including:

The Guide Of American Stainless Steel Tube Standard

The AISI 303 and 304 stainless steel grades are popular alloys because of their corrosion resistance. Both are also austenitic, which means that they are non-magnetic and are workable to some extent. Additionally, it’s ideal for different applications, so you must consider several factors when determining which to use.

While the AISI 303 and 304 stainless steel are somewhat similar, they have unique features that set them apart.

Because the AISI 303 is for free cutting, it’s easier to work with. Thus, it has better machinability compared to grade 304. It’s also easier to fabricate due to its sulfur and selenium content. In contrast, the 304 is not ideal for free-cutting and machining. Moreover, while the 304 is weldable, the 303 stainless steel is not.

Generally, stainless steel is corrosion-resistant. However, because of its altered chemical composition, the 303 stainless steel has less resistance than grade 304. On the other hand, 304 stainless steel is highly corrosion resistant and strong. The downside is that the 304 is vulnerable to pitting, especially in warm, chloride-rich environments.

Depending on the application you’re using it for, the costs you will incur vary. The AISI 303 will typically cost you more than buying 304, but prices change depending on the market. This is because the 303 is developed for heavy machining, which means that it doesn’t require heavy work to form or process. The best way to go around prices is to work with your stainless steel provider.

As mentioned, the stainless steel grade you need will vary depending on the application. Generally, the AISI 303 is ideal for making small components because of its high machinability, including:

Stainless Steel 316 And 316L Graded By The AISI System

The short answer to this is that AISI 303 is NOT food-safe. As mentioned, the AISI 303 is mainly used to produce materials that require heavy machining. Due to this, its corrosion-resistance levels are relatively lower compared to other food-safe stainless steel grades. Generally, creating food equipment involves the use of highly corrosion-resistant alloys. Additionally, the added sulfur or selenium content of AISI 303 increases the risk of sensititazion.

If a magnet sticks to the stainless steel, likely, it’s not 303 stainless steel. This is because AISI 303 is austenitic, meaning it’s non-magnetic and not hardenable through heat treatment.

The density of AISI 303 Stainless Steel coil is approximately 7.8 grams per cubic centimeter or 0.28 pounds per cubic inch, depending on the specific manufacturing process used.

While both 303 and 304 stainless steel coils offer significant strength, the exact values can vary based on the specific manufacturing process used. Generally, 304 stainless steel has higher tensile and yield strength than 303. However, the addition of sulfur or selenium in 303 stainless steel improves machinability but may slightly reduce its overall strength.

AISI 303 Stainless Steel coil is easier to machine than 316 stainless steel but does not have the same level of corrosion resistance. 316 stainless steel has superior corrosion resistance, especially to chloride ions, making it more suitable for marine or chemical processing environments.

You can purchase AISI 303 Stainless Steel coil in bulk from various manufacturers, wholesalers, or metal distributors. These suppliers often have websites or online platforms where you can view their available inventory and request quotes.

Some well-known manufacturers of AISI 303 Stainless Steel coil include Outokumpu, Aperam Stainless, Jindal Stainless, Baosteel.

AISI 303 Stainless Steel coil cannot be hardened by heat treatment. However, it can be hardened somewhat through cold working. Also, it’s worth noting that 303 should not be exposed to temperatures above 800°F (425°C) for extended periods, as it could result in scaling and a decrease in corrosion resistance.

While AISI 303 Stainless Steel coil is known for its machinability, it’s not typically chosen for its formability. It can be mildly formed, but due to its sulfur content, it doesn’t possess the same formability as other stainless grades like 304.

Due to its machinability, AISI 303 Stainless Steel coil is commonly used for parts requiring machining, grinding, or polishing. It is commonly found in screw machine products, aircraft fittings, bushings, electrical switchgear components, gears, and more.

Welding of AISI 303 Stainless Steel coil can be difficult due to its high sulfur content. If welding is necessary, it’s typically recommended to use an over-alloyed filler metal and post-weld annealing to maintain corrosion resistance.

AISI 303 Stainless Steel coil can resist oxidation up to 1700°F (927°C), but it’s not recommended for use in temperatures over 800°F (425°C) for prolonged periods. High temperatures can lead to scaling and a decrease in corrosion resistance.

If the project requires a material that is highly machinable and exhibits good strength and corrosion resistance, AISI 303 Stainless Steel coil is an excellent choice. It’s important to consider the specific needs of the project and the environment the material will be exposed to. With its unique properties, AISI 303 Stainless Steel coil provides a strong, durable, and cost-effective solution for a variety of applications.

The price of AISI 303 Stainless Steel coil is influenced by various factors, such as the cost of raw materials, production costs, supply and demand in the market, and global economic conditions. It’s always a good idea to check with several suppliers for the most competitive pricing.

A reliable AISI 303 Stainless Steel coil manufacturer should have a proven track record of supplying high-quality products. Look for certifications and adherence to international quality standards. Also, consider their production capacity, delivery times, customer service, and any value-added services they offer.

Purchasing AISI 303 Stainless Steel coil from a wholesaler often allows for lower pricing due to the volume of purchase. They may also have a wider range of products and offer quicker delivery times. Additionally, reputable wholesalers often have quality assurance processes in place, ensuring that the products meet the necessary standards.

In conclusion, AISI 303 Stainless Steel coil is a versatile material that offers several advantages, including good machinability and reasonable strength and corrosion resistance. However, each project has unique requirements, so it’s crucial to assess whether AISI 303 is the best choice based on the project’s specific needs.

Stainless steel is an ideal material that you can use in many different applications. However, knowing the correct grade for your project is crucial, as it determines if the grade you have is appropriate for use. Whatever grade of stainless steel you need, Yaoyi offers various stainless steel products in the 300 series. These include fasteners, tubing, and plates that are ideal to fit your needs.