AISI 304 Stainless Steel is a name synonymous with quality and versatility in numerous industrial applications. This comprehensive guide explores everything from the unique properties and applications of AISI 304 Stainless Steel to its testing methods, storage, handling, and performance in various environments. Whether you’re a seasoned professional or new to the world of AISI 304, this article is designed to inspire and educate, opening a world of possibilities with this remarkable material. If understanding AISI 304 Stainless Steel is vital to your endeavors, you’ve come to the right place.

When it comes to stainless steel, AISI 304 is one of the most recognized and widely used grades. It’s more than just a number; it’s a symbol of quality, strength, and versatility. Let’s take a closer look at this fascinating material.

Definition: AISI 304 Stainless Steel, also known as SAE 304 stainless steel, is a common grade of stainless steel that provides excellent corrosion resistance and formability.

Comparison with SS 304: There is no difference between AISI 304 Stainless Steel and SS 304; they refer to the same material. AISI refers to the American Iron and Steel Institute standard, while SS stands for stainless steel.

Composition: AISI 304 Stainless Steel contains 18% chromium and 8% nickel. It’s known for its excellent weldability.

Uses: AISI 304 Stainless Steel is used for a variety of applications, from kitchen utensils to industrial machinery.

Manufacturing Process: This steel is made through hot rolling, and its thickness is precisely controlled to within 0.005mm.

Quality Assurance: Quality is tested through spectrometry and other advanced techniques to ensure the exact chemical composition.

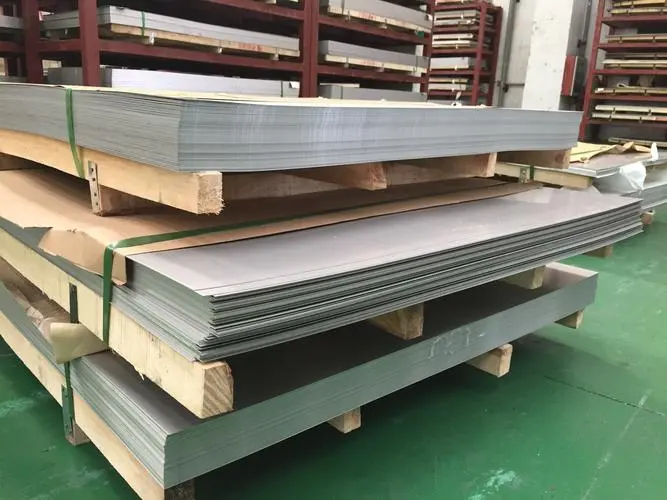

Products: AISI 304 Stainless Steel products include coil, sheet, and foil. These are typically provided by reputable suppliers like Yaoyi Stainless Steel.

Mechanical Properties: The mechanical properties of AISI 304 Stainless Steel include a balanced combination of strength, hardness, and ductility.

Availability: AISI 304 is widely available and can be sourced from major steel companies like Baosteel.

aisi 304 vs ss 304 – As mentioned, there’s no difference between AISI 304 and SS 304, as they are two names for the same material.

Table: Comparison Between AISI 304 Stainless Steel and SS 304

| Property | AISI 304 Stainless Steel | SS 304 |

|---|---|---|

| Composition | 18% Cr, 8% Ni | 18% Cr, 8% Ni |

| Applications | Kitchenware, industrial equipment | Kitchenware, industrial equipment |

| Source | Yaoyi Stainless Steel, Baosteel | Yaoyi Stainless Steel, Baosteel |

Kitchen Appliances: AISI 304 Stainless Steel is widely used in kitchen appliances like sinks, cutlery, and cookware due to its corrosion resistance.

Industrial Equipment: The durability and resilience of AISI 304 make it suitable for various industrial applications.

Medical Instruments: Its non-reactive nature makes AISI 304 Stainless Steel an excellent choice for medical tools and instruments.

Architectural Structures: Buildings and bridges often use AISI 304 Stainless Steel for both aesthetic appeal and structural integrity.

Automotive Parts: AISI 304 is utilized in the automotive industry for parts that require corrosion resistance and strength.

Aerospace Industry: The robustness of AISI 304 Stainless Steel makes it suitable for aerospace applications.

Marine Applications: AISI 304’s resistance to saltwater corrosion makes it a preferred material in marine environments.

Jewelry Making: AISI 304 Stainless Steel’s shiny appearance is used in jewelry and watches.

Welding Processes: Due to its excellent weldability, AISI 304 is frequently used in various welding applications.

what is 304 stainless steel used for – AISI 304 Stainless Steel is a versatile material used in a wide range of applications, from kitchenware to aerospace components.

Table: Top 5 Applications of AISI 304 Stainless Steel

| Application | Benefits | Industry |

|---|---|---|

| Kitchen Appliances | Corrosion resistance | Consumer |

| Industrial Equipment | Durability | Industrial |

| Medical Instruments | Non-reactive | Healthcare |

| Architectural Structures | Aesthetic appeal | Construction |

| Automotive Parts | Strength | Automotive |

Strength: AISI 304 Stainless Steel offers a good balance of strength, making it suitable for various applications.

Hardness: The hardness of AISI 304 Stainless Steel can be enhanced through proper heat treatment.

Elongation: This material exhibits impressive elongation, allowing for excellent formability.

Corrosion Resistance: AISI 304 Stainless Steel provides superior corrosion resistance compared to other materials.

Weldability: Unlike some other steels, AISI 304 can be welded without losing its desirable properties.

Machinability: AISI 304 is machinable, allowing for a range of manufacturing processes.

Thermal Conductivity: AISI 304 Stainless Steel conducts heat well, suitable for applications that require temperature regulation.

Magnetic Properties: AISI 304 is non-magnetic in its annealed state but may become magnetic when cold worked.

Toughness: AISI 304 Stainless Steel possesses remarkable toughness, resisting fractures even under severe conditions.

aisi 304 stainless steel mechanical properties – AISI 304 Stainless Steel’s mechanical properties include its strength, hardness, elongation, and more, making it versatile and suitable for various applications.

Table: Comparison of AISI 304 Stainless Steel Mechanical Properties with Other Materials

| Property | AISI 304 Stainless Steel | Carbon Steel | Aluminum |

|---|---|---|---|

| Strength | High | Moderate | Low |

| Hardness | Moderate | High | Low |

| Elongation | High | Low | Moderate |

| Corrosion Resistance | High | Low | Moderate |

Heat Resistance: AISI 304 Stainless Steel has good resistance to oxidation up to 870°C (1598°F).

Temperature Range: AISI 304 Stainless Steel can be

used in various applications that require operating within its temperature limits.

Oxidation: At higher temperatures, AISI 304 may show signs of oxidation, affecting its appearance.

Heat Treatment: AISI 304 Stainless Steel can undergo heat treatment to improve its high-temperature performance.

Thermal Expansion: It has a moderate coefficient of thermal expansion, meaning it expands and contracts predictably with temperature changes.

Welding: Welding AISI 304 at high temperatures requires proper techniques to prevent undesired effects.

Industrial Furnaces: AISI 304 is used in industrial furnaces due to its heat resistance.

Automotive Exhaust Systems: AISI 304 Stainless Steel’s resistance to high temperatures makes it suitable for exhaust systems.

High-Temperature Applications: Other high-temperature applications include boiler components, heat exchangers, and more.

304l stainless steel – 304L Stainless Steel, a variant of AISI 304, has even better resistance to carbide precipitation during welding and is preferred for high-temperature applications.

Polishing: AISI 304 Stainless Steel can be polished to a high gloss, enhancing its appearance.

Passivation: To increase corrosion resistance, AISI 304 can undergo passivation, forming a protective oxide layer.

Heat Treatment: AISI 304 Stainless Steel can be heat-treated to improve its mechanical properties.

Plating: Various plating methods can be applied to AISI 304 for decorative or functional purposes.

Etching: Etching can be used to create detailed patterns or markings on the surface of AISI 304.

Welding: Proper welding techniques must be applied to ensure the integrity of AISI 304 Stainless Steel.

Coating: Protective coatings can be applied to AISI 304 to enhance its resistance to specific environments.

Anodizing: Although not common for stainless steel, anodizing can be used to form a controlled oxide layer.

Abrasive Blasting: AISI 304 can be treated with abrasive blasting to create various surface textures.

what is aisi – AISI stands for American Iron and Steel Institute, and AISI 304 Stainless Steel refers to a specific standard for this popular stainless steel grade. Various surface treatments can enhance its properties.

Composition: AISI 316 contains molybdenum, making it more corrosion-resistant than AISI 304.

Corrosion Resistance: AISI 316 is more suitable for environments with chlorides and salt exposure.

Strength: Both AISI 304 and 316 offer similar strength levels, suitable for various applications.

Cost: AISI 316 generally costs more than AISI 304 due to its enhanced properties.

Applications: AISI 316 is often used in marine environments, while AISI 304 is used in a wider range of applications.

Machinability: Both types of stainless steel can be machined, although AISI 316 may require specialized tools.

Weldability: Both AISI 304 and 316 are weldable but may require different techniques.

Heat Resistance: Both grades offer similar heat resistance but may vary in specific high-temperature applications.

Availability: AISI 304 is more widely available than AISI 316, which may affect sourcing decisions.

aisi 316 – AISI 316 is another common stainless steel grade with added molybdenum for increased corrosion resistance, often compared to AISI 304.

Table: Comparison Between AISI 304 and AISI 316 Stainless Steel

| Property | AISI 304 Stainless Steel | AISI 316 Stainless Steel |

|---|---|---|

| Composition | 18% Cr, 8% Ni | 16-18% Cr, 10-14% Ni, 2-3% Mo |

| Corrosion Resistance | High | Very High |

| Applications | General use | Marine environments |

| Cost | Lower | Higher |

Hardness Testing: AISI 304 Stainless Steel’s hardness can be tested using specialized equipment.

Chemical Analysis: Spectrometry and other techniques are used to determine the exact chemical composition.

Elongation Testing: Specialized machines can measure the elongation properties of AISI 304.

**Visual Inspection

:** Trained inspectors can identify defects or inconsistencies in AISI 304 products.

Microstructure Analysis: Microscopy can be used to analyze the microscopic structure of AISI 304 Stainless Steel.

Tensile Testing: Measuring the tensile strength of AISI 304 helps in assessing its suitability for specific applications.

Corrosion Testing: Different methods can be used to test the corrosion resistance of AISI 304.

Surface Finish Analysis: Surface analysis ensures that the finish meets specific standards or requirements.

Ultrasonic Testing: Non-destructive ultrasonic testing can detect internal flaws in AISI 304 products.

AISI 304 Stainless Steel coil – Quality testing for AISI 304 Stainless Steel coils includes a series of tests to ensure they meet the required standards.

Certificates: Genuine AISI 304 Stainless Steel products come with certificates of compliance.

Chemical Analysis: Chemical testing can verify the exact composition of AISI 304 Stainless Steel.

Magnet Test: A magnet test can distinguish genuine AISI 304 from other ferromagnetic stainless steels.

Visual Inspection: Experienced inspectors can often identify genuine AISI 304 based on appearance.

Weight Test: Genuine AISI 304 Stainless Steel has a specific weight that can be measured.

Suppliers: Purchasing from reputable suppliers guarantees the authenticity of AISI 304 products.

Surface Finish: Genuine AISI 304 will have a consistent and high-quality surface finish.

Price: Genuine AISI 304 Stainless Steel will likely have a price consistent with its quality.

Trade Associations: Trade associations and standards organizations can provide information on genuine AISI 304 suppliers.

AISI 304 Stainless Steel sheet – Identifying genuine AISI 304 Stainless Steel sheets involves careful inspection and verification through various tests and certifications.

Storage Conditions: AISI 304 Stainless Steel should be stored in dry, clean, and well-ventilated areas.

Handling Precautions: Proper handling techniques should be followed to avoid damage to AISI 304 products.

Protection: AISI 304 should be protected from corrosive substances during storage and handling.

Temperature: Storing AISI 304 in controlled temperature conditions helps in maintaining its quality.

Stacking: Proper stacking methods should be used to prevent deformation or damage to AISI 304.

Cleaning: Regular cleaning and inspection of AISI 304 are necessary to ensure its integrity.

Transportation: Special care should be taken during the transportation of AISI 304 to avoid scratches or dents.

Moisture Control: Moisture can affect the surface quality of AISI 304, so control measures should be implemented.

Packaging: Proper packaging materials and techniques should be used for AISI 304 Stainless Steel.

AISI 304 Stainless Steel foil – Special care should be taken when storing and handling AISI 304 Stainless Steel foil, as it is more delicate and prone to damage.

Corrosion Resistance: AISI 304 Stainless Steel offers good corrosion resistance but may suffer in high chloride environments.

Marine Applications: AISI 304 can be used in various marine applications, but with some limitations.

Saltwater Exposure: Prolonged exposure to saltwater may lead to pitting or crevice corrosion in AISI 304.

Coating Options: Protective coatings can enhance AISI 304’s performance in marine environments.

Maintenance Requirements: Regular maintenance is necessary to keep AISI 304 in good condition in marine applications.

Material Selection: AISI 316 may be a better choice for certain marine environments due to its higher molybdenum content.

Inspections: Regular inspections and monitoring of AISI 304 in marine environments are essential.

Chloride Exposure: AISI 304 is less suitable for environments with high chloride exposure, such as seawater.

Cost Considerations: AISI 304 is often chosen for marine applications due to its balance of cost and performance.

aisi 304 vs ss 304 – Comparing AISI 304 vs SS 304, it is essential to note that both refer to the same material, but AISI denotes a specific standard. Understanding this distinction can be important in marine applications, as standards may vary based on region and application.

The in-depth analysis of AISI 304 Stainless Steel across different questions offers comprehensive insights into this versatile and widely used material. Understanding its properties, applications, quality testing, storage, handling, and more provides a solid foundation for selecting and working with AISI 304 in various industries.

AISI 304 Stainless Steel, often referred to as 18/8 stainless steel, comprises 18% chromium and 8% nickel. It’s a grade that has stood the test of time since its discovery in the early 20th century. A hallmark of quality, AISI 304 revolutionized the metal industry, enabling new levels of corrosion resistance and aesthetics.

The stainless steel world practically swears by AISI 304. From Yaoyi’s 0.01~ 0.05mm stainless steel foil to large infrastructure projects, this steel grade has left an indelible mark. It’s widely celebrated for its balance of performance and cost, providing a go-to option for various industries.

What makes AISI 304 so sought after? Here’s a snapshot:

With so many applications, it’s no wonder that AISI 304 is often referred to as the “workhorse” of the stainless steel family.

AISI 304 is not just popular; it’s powerful. It packs a punch in the properties department. Let’s unravel what lies beneath the shiny surface.

The secret sauce of AISI 304 lies in its unique chemical composition. Here’s a quick rundown:

| Element | Percentage |

|---|---|

| Chromium | 18-20% |

| Nickel | 8-10.5% |

| Carbon | ≤0.08% |

| Manganese | ≤2% |

| Silicon | ≤1% |

| Phosphorus | ≤0.045% |

| Sulfur | ≤0.03% |

These elements, combined in just the right way, give AISI 304 its famed corrosion resistance.

The chromium in AISI 304 forms a passive layer of chromium oxide, acting like a shield against corrosion. This means that even if it’s scratched or damaged, it can heal itself, keeping rust at bay. Interested in more? Explore the complete guide to AISI 304 stainless steel on Yaoyi’s website.

Understanding AISI 304 requires delving into its mechanical muscle. It’s more than a pretty face; it’s a strong and resilient material, too.

AISI 304 is known for its impressive tensile strength, ranging from 515 to 860 MPa, depending on the treatment. With a Brinell hardness number around 123, it provides a perfect balance of strength and formability. Learn more about 304 stainless steel hardness here.

Elongation is where AISI 304 truly shines, boasting an impressive rate of 40-50%. It means that this steel can stretch without breaking, providing flexibility in applications. Yield strength varies between 205 to 310 MPa, proving that AISI 304 is not just tough but elastic too.

When it comes to thermal conductivity, AISI 304 sits at 16.2 W/m·K, providing efficient heat transfer. Its electrical resistivity of 7.2 x 10^-5 Ω·m makes it a non-ideal conductor, but that’s an advantage in specific applications like insulation.

AISI 304’s properties make it a superstar in various fields. From your kitchen to the local bridge, here’s where you’ll find it:

AISI 304’s resilience and aesthetic appeal make it a prime choice for industrial machinery. From processing plants to assembly lines, it’s in the very heart of industry.

AISI 304 is a building block of modern construction. Its corrosion resistance and strength make it ideal for structures that stand tall. Skyscrapers, bridges, and transportation hubs all lean on AISI 304.

Look around your kitchen, and you’ll likely see AISI 304 in action. Refrigerators, ovens, and even your favorite Yaoyi 0.05mm 304 stainless steel foil are crafted from this amazing material.

It’s not just about utility; AISI 304 brings elegance into homes. Picture frames, sculptures, and decorative accents all gleam thanks to this versatile stainless steel.

Choosing the right stainless steel can feel like a maze. Here’s a guide to help you navigate:

Choosing between grades? It’s not just about numbers; it’s about finding the perfect fit for your specific needs.

AISI 304 isn’t just strong; it plays nicely with tools, too. From laser cutting to punching and bending, its formability makes it a craftsman’s dream. Check out this guide on 0.03mm stainless steel foil for precision fabrication.

Want a mirror finish or a textured look? No problem! AISI 304 can be finished in various ways, from brushing to electropolishing. It’s like a canvas waiting for an artist’s touch.

From TIG to MIG, AISI 304 welds like a charm. But it’s not just about melting metal; it’s about creating strong bonds that last. Yaoyi’s range of stainless steel foil products exemplifies AISI 304’s weldability.

Welding AISI 304 requires attention to detail. Controlling heat, using proper filler materials, and post-weld cleaning are vital. It’s not just welding; it’s sculpting strength.

When it comes to AISI 304, quality isn’t a luxury; it’s a standard. Compliance with ISO 9001 ensures that every piece of stainless steel meets global quality benchmarks.

At Yaoyi, quality isn’t just a promise; it’s a culture. In-house testing and rigorous control processes ensure that AISI 304 isn’t just good; it’s the best.

Is it tough enough? Hardness testing of AISI 304 ensures that it can take a punch. From Brinell to Rockwell, every piece is tested and trusted.

A perfect blend of chromium, nickel, and iron, AISI 304’s chemical composition is scrutinized in labs. It’s not just metal; it’s a precise recipe for excellence.

AISI 304 isn’t just about today; it’s a vision for a sustainable tomorrow. Its recycling potential ensures that it lives on, not just in products but in the planet’s future.

From production to disposal, AISI 304 complies with stringent environmental regulations. It’s not just a material; it’s a commitment to a greener Earth.

Working with AISI 304 isn’t just business; it’s about building communities and empowering lives. From responsible sourcing to ethical practices, it’s a metal with a moral compass.

Picking a supplier isn’t just about pricing. Quality, reliability, and support play crucial roles. Partnering with the right supplier, like Yaoyi, ensures that you’re not just buying metal; you’re investing in success.

Quality isn’t accidental. At Yaoyi, every 304 stainless steel coil undergoes rigorous quality control. It’s not just a product; it’s a promise.

From small businesses to industry giants, working with Yaoyi means partnering in excellence. Their comprehensive products range, including AISI 304 stainless steel, epitomizes quality.

AISI 304 isn’t magnetic? Think again! There are common myths, but the truth is in the details. Dive into the complete guide to AISI 304 stainless steel to debunk them.

Soap and water are often enough. Maintaining AISI 304 doesn’t require magic; just regular cleaning and care.

From foil to coil, AISI 304 is widely available. Check out Yaoyi’s AISI 304 stainless steel foil price for competitive options.

AISI 304 isn’t done yet. With

research, innovations, and advancements, it’s continuously evolving to serve the ever-changing demands of modern industries.

As industries move towards greener, sustainable solutions, AISI 304’s recyclability and low environmental impact make it a frontrunner. It isn’t merely about the shiny, rust-resistant surface but a deeper commitment to the planet’s well-being.

With the rise of smart factories and Industry 4.0, the role of AISI 304 isn’t restricted to being a passive material. Integrated sensors, IoT compatibility, and enhanced functionality make AISI 304 not just a part but a partner in modern manufacturing.

Yaoyi is not just riding the wave; they’re shaping it. With continuous investment in R&D, partnerships with research institutions, and listening to customer feedback, Yaoyi aims to redefine the boundaries of what’s possible with AISI 304 stainless steel. Explore more about their journey and mission on their About Us page.

Navigating the world of stainless steel, especially AISI 304, is like exploring an intricate tapestry of art, science, and innovation. With every weave, there’s a story of strength, resilience, and a promise of longevity.

Whether you’re an architect aiming for a sustainable design, an automaker looking for reliable materials, or merely a curious mind, understanding AISI 304 is a deep dive into the confluence of technology and nature.

And with partners like Yaoyi, who’ve dedicated their craft to perfecting the art of stainless steel, you’re not just buying a product. You’re becoming part of a legacy. Dive deeper into their extensive stainless steel foil product range, and you’ll find a blend of tradition, innovation, and a commitment to excellence.

Since many products rely on the reliability of their spring components, it is essential to choose springs of high quality that will not fail beforehand. Premature spring dysfunction can be caused by many factors, including defective design, poor quality materials or lower demand.

Although a spring could seem like a small part of a larger system, a spring’s functional failure might lead to a failure. Therefore, before making a purchase, the consistency of the materials used to create a spring and the process must be considered.

In general, springs are made of stainless steel. Until forming a spring, the Spring maker may either use pre-hardened steel or even harden the Spring after forming. Music wire, stainless steel, chrome silicone, oil-tempered wire and chrome vanadium are among the most popular spring stones used.

You can get the more cost-effective 301 stainless steel material from Yaoyi. Thickness 0.1 mm~0.3 mm, width 550-600 mm cold rolled stainless steel coil.

The various materials are suitable for a variety of conditions. Some materials and their basic conditions are given below:

Music Wire is used for applications with a high strength and a high quality overall spring.

Stainless steel produces a commodity that works well in humid conditions because it does not rust.

Chrome Silicon is a higher power and efficiency variant of the tempered oil line that is used in higher temperatures.

Oil Tempered Wire is not commonly used for the best or most consistent product for many common applications.

Chrome Vanadium has a chrome silicone-like quality structure and is suitable for high temperatures.

Actually, springs have a linear and progressive division into 2 basic forms. A gradual spring has a variable spring rate, which means that each spring has a defined spring rate dependent on the particular set for which the spring is built. The performance is higher because the driver can predict the suspension movements more effectively.

Each coilover kit is designed to accommodate the shocks of the kits. The effect of the road conditions was absorbed. They ensure that the tires remain in contact with the road when combined with the shock absorber. Their specification has been measured using theoretical models with a high degree of precision.

While certain materials have often been considered a spring material, not all alloys for spring use are specifically made. An ideal spring material has high strength, high elastic limit and low modulus characteristics. Since the springs are inherently durable structures, they have wide deflections that require an extensive range of elasticity.

In light of cost/benefit, other characteristics are taken into consideration, such as resistance against corrosion, fatigue, formability, electrical conductivity, magnetic permeability, and availability and cost. Since they need so many different features, the most common are stainless steel springs.

Although the surface quality is not specifically defined by national requirements, it also affects fatigue ability. Materials with high surface integrity are best used for fatigue applications, particularly in the region of high cycle.

Because of its unique characteristics, stainless steel springs have become impressively common in recent years. Corrosion resistance is one of the most common reasons for choosing steel springs for industrial use. Stainless steel springs are resistant to chemicals and corrosion, making them the right option for industry and manufacturing.

Stainless steel coilover springs are made of different unique and correct materials, but the following are the most suitable grades:

The most common and economic form of stainless steel wire is Stainless Steel 302 A-313. This type of material will do the job if your spring design is needed in a humid or corrosive setting. Stainless Steel 302 buckets can withstand higher temperatures than your standard high-carbon bucket. It can withstand up to 250 degrees F (228 degrees C). Stainless Steel 302 is the softest in tensile strength, and is also flexible, which gives a strong elastic limit for your spring and also a little less flexible.

The most “extravagant” sort of stainless steel wire, Stainless Steel 316 A-316. The two are as effective for resisting moist/moist conditions in this kind of stainless steel. It is also non-magnetic at around 85% and can withstand higher temperatures. It is also an even safer form of stainless steel, so in medical springs it is recommended. This form of material is the weakest of the above materials.

In terms of the pricing of stainless steel materials, 17-7 A-313 is the next in the series. This material can also perform as is done in moist/corrosive conditions with Stainless steel 302, so the only reason you choose this material is to get a harder/stronger form of material than Stainless Steel 302. This gives the spring more power / strength, without altering spring dimensions. It has a better tensile strength. It can withstand higher temperatures; it can withstand up to 650 °F (343 °C).

In the suspension system a belt spring in combination with struts and shocks is used in small cars and light trucks.

First, the springs absorb road impact easily, support the weight of the vehicle and keep all four wheels in contact with the road and support overall performance and movement of the vehicle.

These springs may also be used for opening or keeping the glove box closed. It is used for controlling movement of the valve in the engine and for comfortable driving in car seats.

Some headlights can also contain springs to absorb road effects and prevent bulbs from crashing. Subsequently, A coilover spring may be produced from silicone for automotive purposes, because it can withstand higher heat and effect rates than most other materials.

The coilover spring can be used for industrial applications in automatic doors, garage doors or loading hatches. In repeated cases with garage doors, where there are repeat openings and closing motions, it is critical that the fountains work consistently.

Since energy is stored and released as it is used by twisting the spring. These springs generally consist of carbon, titanium or copper for long service life and stability.

However, a proper spring size to maintain a properly balanced garage door proportional to the weight of the item supported is required for optimum performance.

The springs work automatically by keeping the resistance to the doors constant, releasing this voltage and opening the doors when the sensor is disabled.

Coil or helical fountains provide almost all business and technical ventures with virtual basis. The anchors can be used and existing foundations can be strengthened in new buildings.

At this point, they will support and remove sidewalks. They can also be used in safety valves to shut or open pipelines if appropriate.

In consideration, the springs may be used for releasing a consistent and measured pressure level, to avoid damage or to minimize the risk of failure of the device. Mechanical support and versatility are essential in bridges and rail buffers.

These functions can be provided by coil springs and can be used as dampers for vibrations. The shocks and impacts generated by a train in use are absorbed by this.

Ultimately, springs must resist corrosion and always operate continuously because weather can be a harmful factor.

Quelling can be found in various ammunition applications and is a key component of the function and reliability of firearms. In precise parts, such as pistol springs, springs, springs, or springs, you will find them.

As used in detonators, the springs are flattened and released before activating in a compressed state. The consistent performance of these springs is critical, irrespective of application. This is vital for the safety of consumers and those in the immediate environment.

This is because the material has a high tensile strength to withstand shocks and can help minimize the tension and fatigue that a weapon releases on a repeated basis.

A bowling spring is used for residential applications to sustain and reduce the impact of mattresses and layers and provides a bowling effect. Typically, these springs are in steel.

In residential applications, a coil spring is used for support and reducing impact in mattresses and layers and provides a coiling effect. These springs are usually made of steel.

Hence, the support can be adapted to the user’s personal preference with mattresses. The spring’s size or thickness defines its strength by a thicker spring that provides a stronger support.

This form of spring is used to store energy in old-fashioned wind-up watches and clocks. Then, this energy is released slowly at a steady pace.

Finally, they are often used in kid pop-up toys and music boxes or in a spring loaded rat trap that requires a strong, short energy explosion.

Are coilover springs more costly than springs? Quality coverings are more costly than a simple collection of lowering springs. This is meaningful since a group of coilers is basically an integrated, matching shock and spring. It is impractical to demand the same price as a group of lowering springs for a package of coilover springs that comes with springs.