If you know low-nickel-chromium-manganese austenitic stainless steel, then you must have heard of steel grades such as J1, J3, J4, 201 and J2 stainless steel. People have been using AISI 304 on a large scale, but compared to AISI 301, it lacks hardness and strength and is expensive. Therefore, YAOYI stainless steel produced J2 stainless steel, which added nitrogen to the steel in an appropriate amount, resulting in its strength in the annealed state higher than that of SUS 304.

The J2 produced by Yaoyi also adds the content of copper, which makes it higher in tensile properties than 304 with the same strength, reduces the work hardening rate, and is conducive to cold working. Due to the addition of nitrogen, copper and manganese content and the reduction of precious metal nickel and chromium content, the J2 stainless steel produced by yaoyi is cheaper than 304, and it also has the formability and weldability of 304 stainless steel. However, due to the reduction of nickel and chromium content, the corrosion resistance of J2 stainless steel is lower than 304, but better than 430.

Stainless steel is one of the most used iron alloys because of its durability, long life cycle, and non-corrosive property. Hence it is used in many applications from food kitchenware, medical, automotive to construction applications. It is very efficient and effective that many industries rely on and use it for their products and machinery.

Stainless steel is not just one metal alloy. It consists of various alloys, mainly chromium, making it non-corrosive. The other metals or elements used are iron, carbon, nickel, manganese, and copper, to name a few. Besides that, stainless steel also has different grades that correspond to its metal features and composition.

These different grades show the stainless steel capabilities and strength.

You will usually see stainless steel graded with numbers like 275 or 316. This grade is the deforming point of the stainless steel, but there are also grades with letters and numbers. Some of them are J1, J2, J3, J4, and so on.

This grade refers to stainless steel that is tested with an impact test at a specific temperature. For example, J2 steel is tested with 27 joules of energy at -20 degrees temperature. To know more about stainless steel specifical J2 grade, read on.

J2 stainless steel has medium content of chromium, giving it anti-corrosive properties. Thus, you can expect that it won’t get easily affected by weather, acids, detergent solutions, water, petroleum products, or moisture. For its strength, it has 0.128% of carbon, giving you good enough power.

It also has good machining qualities, which means that it is easy to cut and work with. Its good strength and anti-corrosive properties make J2 stainless steel widely used, especially as surgical steel. Aside from surgical instruments, it is also used in various cutting tools like knives, scissors, etc.

J2 Stainless Steel, also known as 420J2 Stainless Steel, is a grade of martensitic stainless steel. This type of steel is known for its hardness and capability of attaining, after heat treatment, very high hardness, strength, and toughness. The carbon content of this stainless steel grade ranges from 0.26% to 0.4%, and the chromium content falls between 12% and 14%. These attributes result in a stainless steel grade that offers reasonable corrosion resistance, particularly in mild environments, and exceptional hardness following heat treatment.

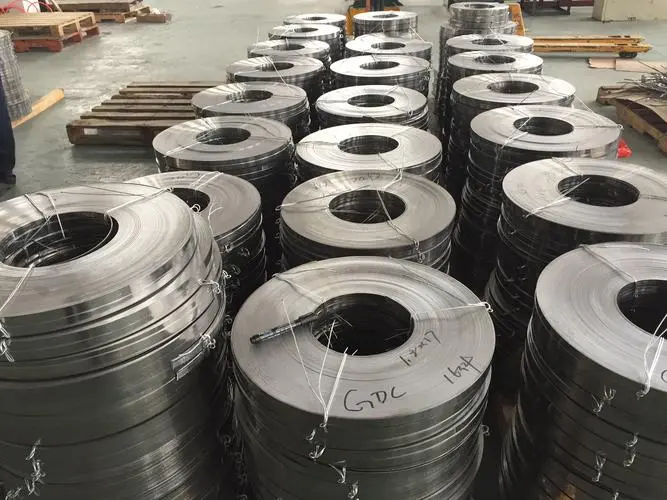

Strip

Platform Plate

Tube

Coil

Stainless Steel Belt: Characteristics, Advantages, and Applications

|

C |

Mn |

P |

Cr |

Ni |

S |

Si |

|

0.129 |

9.6 |

≤0.045 |

13.46 |

1.40 |

≤0.01 |

0.48 |

High-temperature resistance 800℃,

Tensile strength σb (MPa) ≥ 520,

Conditional yield strength σ0.2 (MPa)≥200.

Elongation δ5 (%)≥25

Hardness ≤187HB, ≤90HRB, ≤210HV

Density 20℃ g/cm3

Melting point (℃): 1398~1454

Stainless Steel AISI 316Ti (S31635) By The AISI System

J2 stainless steel falls under Austenitic stainless steel. It is well-known for its austenitic microstructure or face-centered cubic crystal structure. These stainless steel are produced by creating a steel alloy, primarily of nickel and a combination of nitrogen and manganese.

This induces an environment to maintain the austenitic structure at different ranges of temperature or melting point.

The Austenitic stainless steels are further divided into two major types: The 200 series and the 300 series. Between these two, J2 stainless steel is under the 200 series. It’s differentiated by its composition of chromium, manganese, and nickel to create an alloy with a higher strength rate than the 300 series.

Then, J2 steel was classified as part of the J series under the 200 steel grade since they are hardened through cold processing. Unlike other steel that have numbers as grade to indicate the minimum yield strength, the J series is different. It is classified and identified by conducting the Charpy impact test at 27 joules of energy at a specific temperature.

Particularly J2 steel had undergone 27 joules of energy impact test at -20 degrees temperature. Aside from that, J2 steel grade doesn’t have the usual amount of molybdenum. It’s the difference that sets it apart from most stainless steel in other series.

Molybdenum increases strength, resistance to corrosion and wear, malleability, and electrical conductivity. With this, you can expect that it won’t have the maximum yield strength. Most significantly, for applications that would require bending of the steel.

It also has a relatively more minor copper and sulfur content than the other J series steel. However, this steel grade is excellent enough for cookware, furniture, and other applications that don’t need heavy-duty strength.

Additionally, this stainless steel is easy to polish and perfect for making flat plate materials. Such because it will produce excellent byproducts with excellent surface appearance. It is also why many manufacturers use it for ornaments and kitchenware like knives and other plate-like materials.

What is J4 Stainless Steel? (And What Is It Used For)

J2 stainless steel is an excellent material in external and construction applications. It consists of 0.128% carbon, 1.37% nickel, 13.29% chromium, 9.57% manganese, 0.33% copper, 0.49% silicon, 0.045% phosphorus, 0.001% sulfur, and 0.155% nitrogen.

In terms of composition, the stainless steels under the J series are relatively similar in chromium and nickel content percentages. This is expected since these components are the reason for the anti-corrosiveness of the J series. However, this series is comparatively different in terms of carbon content. That is why it can translate to the usability of stainless steel in many applications.

Within the J series, J2 is second on carbon content which has a significant implication on the hardness of this material. The carbon content of most stainless steel is a good indication of the hardness of the product. The higher the carbon content, it is expected that the steel alloy has a high rate of hardness and increased strength.

On the other hand, high carbon content can also indicate that stainless steel is more susceptible to cracking and brittleness. That has significant implications for the material’s weldability, especially for commercial purposes or applications.

J2 stainless steel is still a good ally since it has impressive strength and non-corrosive properties. And so, it’s ideal in many applications that do not require intensive malleable requirements.

However, the J2 steel grade can only be welded to a certain degree, riveted, or bolted in most applications. Hence, J2 steel is still a widely used steel, and many manufacturers use it as a blade for cutting tools. It is also used in many surgical instruments since it’s easy to work with.

Its hardening capability is excellent as well, which is why this grade of metal is in demand. Many manufacturers also use this to create daggers and other tools for self-defense.

J3 Stainless Steel : A Complete Guide For Importers

As mentioned earlier, J2 steel has good strength, won’t get rust, and easy to work with. Hence it is used in many applications like furniture, ornament tubes, kitchenware, and food processing.

The polishing result with this grade of stainless steel is excellent, but you will have a problem when you bend it. It can easily break when you try turning the steel, especially if it’s an ornament tube or flat plate.

Aside from that, this type of grade can still be a suitable replacement for stainless steel grade 321, 316, and 310. In general, it will work with most applications. Like J2 stainless steel, J2 has low-cost manganese, copper, and nitrogen, making it inexpensive, unlike other steel.

J2 stainless steel is very efficient, and has good strength, easy to form, and is welded to a certain point.

J2 steel, with its strength and anti-corrosive property, is used in many tools, even in cookware. Knives and some cutting tools are even made from this material, so you can be assured that it is safe to use, especially food. However, it is not the best stainless steel grade for food that you can find.

The most suited and met all criteria for best food-grade steel is 304 or 18/10 and 18/8 steel.

J2 grade stainless steel is not expensive and can be an excellent alternative to other steel grades that can be costly. Its composition has good strength, anti-corrosive properties, and good machinability, so you won’t have any difficulty in using this steel.

If analyzing cost performance, J2 is a good material for applications. You won’t need intensive requirements such as bendability, ductility, and steel shearing purposes. If you need material for ornament tubes that do not require flexibility, then choose J2 material. It’s more cost-efficient than other stainless steel in the J series.

Since it’s also easy to polish and produce, you can be assured that it will perform excellently. Be careful when selecting this material if you need something easy to bend and flexible for your application.

In this situation, it is better to opt for something more weldable or more ductile such as stainless steel in the 300 series.

How To Find The Right Stainless Steel Supplier

Stainless steel is an excellent steel alloy. It’s been used in many applications from cookware, medical, furniture to construction throughout the years. It has impressive strength and durability and will not easily get corroded with moisture, acids, solutions, or even weather.

The various grades help people to know what quality they should get on the application they want to do.

Moreover, J2 steel has good strength, machinability, and anti-corrosive property and it can be used in various applications. It’s not that expensive, so it can be a great alternative with other metal grades that are not available or expensive. it’s

Don’t be shy to ask the nearest supplier in your area to know more about this stainless steel grade.

ASTM A167: Composition, Properties, and Equivalent Grades

J2 steel is a common choice for knife blades because of its balance between hardness and toughness. While it’s not as durable or as long-lasting as some high-end knife materials, J2 steel offers a sharp edge that can withstand considerable use. In addition, J2 steel knives are typically more affordable than those made from premium materials, making them a popular choice for everyday use.

Knives made from J2 steel are known for their sharpness and durability. Because of the material’s hardness following heat treatment, these knives can maintain a sharp edge even after repeated use. Additionally, J2 steel is fairly easy to sharpen, which means you can restore a sharp edge to your knife without much effort. However, it’s important to note that J2 steel isn’t as resistant to wear and tear as some other types of stainless steel, so these knives might not last as long as those made from more durable materials.

VG10 is a higher-end stainless steel that’s known for its exceptional edge retention and corrosion resistance. In comparison, 420J2 is a lower-end stainless steel that’s still quite capable but doesn’t offer the same level of performance as VG10. While VG10 knives are typically more expensive, they also tend to last longer and perform better over time.

420J2 stainless steel is categorized as a martensitic stainless steel. This category of stainless steel is characterized by their capability to gain high hardness upon heat treatment. This specific grade has a carbon content that ranges from 0.26% to 0.4% and chromium content that ranges from 12% to 14%. This composition enables it to achieve high hardness and reasonable toughness.

J2 steel can be used to make swords, but it’s not the optimal choice. The strength and toughness of the steel are important when crafting swords, and while J2 steel is hard and fairly tough, there are other types of steel better suited to the purpose. High-carbon steels, for instance, tend to be stronger and more durable, making them a better choice for swords that are meant for actual use rather than display.

420J2 steel is a specific grade of stainless steel, and there’s no direct equivalent to it. However, there are other types of stainless steel with similar properties. For instance, 420HC (high carbon) stainless steel is similar in terms of corrosion resistance and hardness but has better wear resistance.