The use of stainless steel foils has expanded rapidly across industrial, commercial, and domestic sectors due to their unique combination of strength, corrosion resistance, thermal stability, and formability. Stainless steel foil is no longer limited to niche engineering tasks; it now plays a visible role in electronics, energy systems, medical devices, food processing, and precision manufacturing.

Manufacturers and buyers searching for reliable material solutions often prefer stainless steel foil because it offers predictable performance even at extremely thin gauges. From micro‑electronics to heavy thermal barriers, this material delivers consistency while supporting modern production demands. At stainless steel foil, stainless steel precision foil products are developed to meet these demanding applications through controlled processing and strict quality standards.

This article presents a detailed, research‑based explanation of stainless steel foils, their grades, applications, advantages, and processing methods, with a clear focus on real‑world use and material behavior.

What Is Stainless Steel Foil?

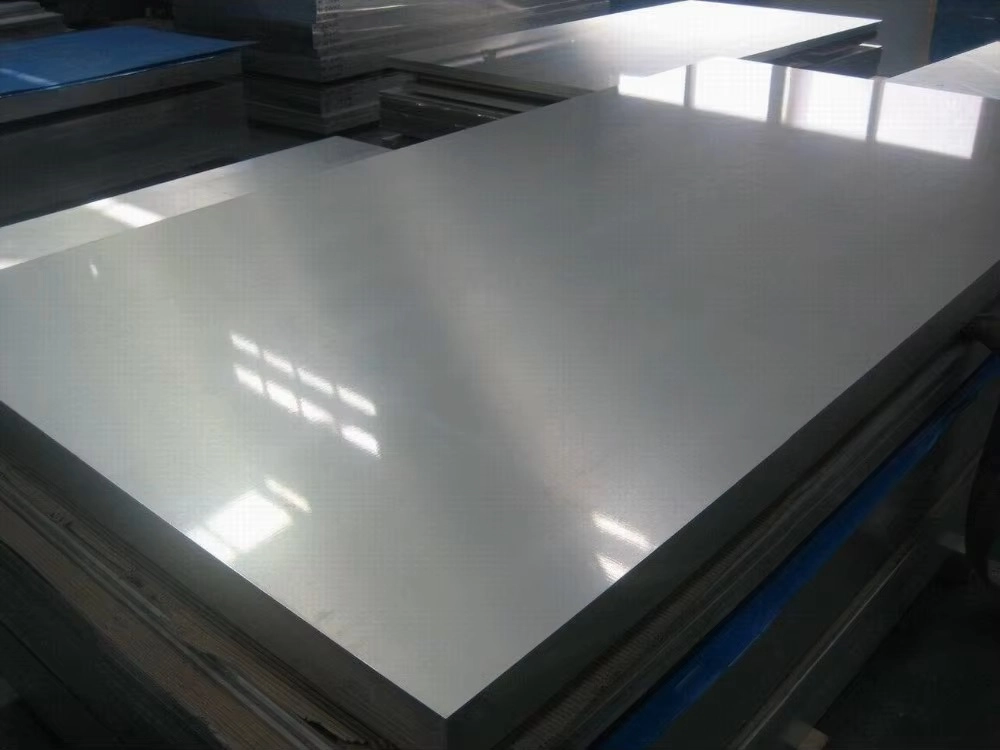

Stainless steel foil refers to flat‑rolled stainless steel material produced in extremely thin thicknesses, generally below 0.2 mm and often reaching micron‑level precision. Unlike thicker strip or plate, foil maintains flexibility while preserving the inherent metallurgical properties of stainless steel.

Stainless steel foil originates from hot‑rolled coils that undergo repeated cold rolling, intermediate annealing, surface treatment, and precision slitting. This controlled process allows manufacturers to achieve uniform thickness, smooth surface finishes, and tight dimensional tolerances. A detailed explanation of the manufacturing journey appears in How Stainless Steel Foil Is Made From Hot Rolled Coil to Ultra‑Thin Precision.

Foils can be supplied in coils or sheets, depending on the end‑use requirement. Common finishes include 2B, BA, and custom polished surfaces, which support both functional and aesthetic applications. A technical overview of stainless steel material fundamentals is available through Wikipedia’s stainless steel reference.

For additional technical explanations, visit What Is Stainless Steel Foils and What Is Stainless Steel Foil.

What Is the Grade of Stainless Steel Foil?

The grade of stainless steel foil determines its corrosion resistance, mechanical strength, temperature tolerance, and compatibility with specific environments. Grades follow international standards such as AISI, ASTM, EN, and JIS.

Common Stainless Steel Foil Grades

| Grade | Structure | Key Properties | Typical Use Areas |

|---|---|---|---|

| 304 / 304L | Austenitic | Good corrosion resistance, excellent formability | Electronics, food processing, general purpose |

| 316 / 316L | Austenitic | Enhanced resistance to chlorides and heat | Medical, marine, chemical equipment |

| 301 | Austenitic | High tensile strength after cold working | Springs, connectors, precision parts |

| 430 | Ferritic | Moderate corrosion resistance, magnetic | Appliances, decorative parts |

| 321 | Austenitic | Stabilized for high‑temperature use | Aerospace, exhaust systems |

Grade selection depends on operating temperature, chemical exposure, mechanical stress, and forming requirements. Heat treatment also affects performance, as explained in 316 Stainless Steel Strip Heat Treatment.

A comparison between molybdenum‑enhanced grades appears in 316 vs 316L Stainless Steel Strip, which helps engineers decide between strength retention and weldability.

Stainless Steel Foils Applications Across Industries

The broad use of stainless steel foils stems from their adaptability to both macro and micro‑scale manufacturing.

Electronics and Electrical Components

Stainless steel foil functions as shielding material, battery casing, flexible circuits, and grounding layers. Thin gauges support miniaturization while maintaining mechanical stability.

Medical and Healthcare Devices

Medical instruments, surgical blades, diagnostic equipment, and implantable components rely on stainless steel foil for biocompatibility and sterilization resistance.

Automotive and Transportation

Automotive exhaust gaskets, sensors, and insulation layers utilize foil for heat resistance and vibration endurance.

Energy and Thermal Systems

Fuel cells, heat exchangers, and insulation barriers employ stainless steel foil for consistent thermal behavior.

Consumer Goods and Appliances

Stainless steel foils contribute to surface panels, heating elements, and internal structural components. Related applications are detailed in Stainless Steel Strips in Home Appliances and How Stainless Steel Coil Is Used in the Production of Consumer Goods.

A full overview of related materials appears in the Stainless Steel Coil Production Process Guide.

Stainless Steel Foil for Cooking and Food Processing

Stainless steel foil supports food‑related applications where hygiene, temperature stability, and corrosion resistance are required. Unlike aluminum foil, stainless steel foil does not react with acidic or alkaline foods.

Benefits in Food Environments

- Maintains structural integrity at high temperatures

- Resists staining and flavor transfer

- Supports repeated cleaning cycles

- Meets food safety compliance standards

Food processing equipment, baking trays, conveyor belts, and thermal covers rely on thin stainless steel foil for consistent performance. Austenitic grades such as 304 and 316 dominate these applications due to their non‑reactive surface chemistry.

Which Grade of Stainless Steel Foil Is Used for the Thermal Insulation Layer?

Thermal insulation systems often require stainless steel foil as a reflective or protective layer rather than a primary insulator.

Preferred Grades for Thermal Insulation

| Grade | Temperature Capability | Reason for Selection |

|---|---|---|

| 304 | Up to 870 °C | Cost‑effective and stable |

| 316 | Up to 925 °C | Improved oxidation resistance |

| 321 | High‑temperature cycling | Titanium stabilization |

Stainless steel foil enhances insulation systems by reflecting radiant heat, protecting insulation cores, and maintaining shape under thermal stress.

Stamping 0.1 mm Thickness Stainless Steel Foil

Stamping 0.1 mm stainless steel foil requires precision tooling, controlled lubrication, and consistent material hardness. At this thickness, material behavior changes significantly compared to a thicker strip.

Key Stamping Considerations

- Uniform grain structure

- Tight thickness tolerance

- Controlled surface finish

- Accurate die clearance

Grades such as 301 and 304 perform well in stamping due to their balance of ductility and strength. Post‑stamping annealing may be applied to relieve stress and restore formability.

Manufacturing support for precision projects is available through Products, which outlines available foil ranges and processing options.

Advantages of Stainless Steel Foils

The growing use of stainless steel foils reflects their technical and economic benefits.

Material Advantages

- High corrosion resistance

- Consistent mechanical strength

- Excellent surface stability

- Compatibility with micro‑fabrication

- Long service life

Production Advantages

- Adaptable to rolling, stamping, and forming

- Supports tight tolerances

- Works with automated manufacturing lines

These benefits allow manufacturers to achieve predictable results across diverse production environments.

How We Deal With Your Stainless Steel Precision Foil Project

At Stainless Steel Foil, each precision foil project follows a structured workflow.

Project Handling Process

- Requirement analysis and application review

- Grade and thickness selection

- Rolling, annealing, and surface treatment

- Precision slitting and inspection

- Secure packaging and global delivery

Technical teams collaborate closely with customers to align material behavior with end‑use requirements. For direct consultation, visit Contact Us.

Industry insights and material updates appear regularly in the Blog section.

Summary

The use of stainless steel foils continues to grow across electronics, medical devices, food processing, thermal insulation, and precision stamping industries due to their strength, corrosion resistance, and dimensional accuracy. Ultra-thin stainless steel foil offers reliable performance even in demanding environments where temperature stability, hygiene, and mechanical consistency remain essential.

Understanding material grades, thickness control, and processing methods helps manufacturers select the right foil for each application. From cooking and consumer appliances to insulation layers and micro-components, stainless steel foil supports long service life and consistent output. Detailed product ranges and technical support are available through stainless steel products, while in-depth material knowledge can be explored in the stainless steel foil technical resource center.

For custom requirements, material selection guidance, or project consultation, manufacturers can connect directly with the engineering team at Stainless Steel Foil to ensure each precision foil project meets performance and quality expectations.

FAQs

What thickness range defines stainless steel foil?

Stainless steel foil typically measures below 0.2 mm, with ultra‑thin products reaching 0.01 mm or less.

Which stainless steel grade works best for corrosion resistance?

Grade 316 offers strong resistance in chloride‑rich and chemical environments.

Can stainless steel foil handle high temperatures?

Yes, selected grades perform reliably at elevated temperatures depending on alloy composition.

Is stainless steel foil safe for food contact?

Austenitic grades such as 304 and 316 meet food safety requirements and resist contamination.

Where can precision stainless steel foil be sourced?

Precision stainless steel foil products and technical support are available through stainless steel foil.