Since its foundation 25 years ago, Yaoyi has been engaged in the stainless steel manufacturing business. It is our goal to supply the very competitive quotations to assist your organization or project. When we were offering a wide range of stainless steel products as well as dependable stainless steel solutions, a question came to us: Is 301 stainless steel magnetic? After reading this article, you can find the answer.

Yes to different degrees. The alloying components, the atomic structure of grain and the quantity of cold work during production affect the magnetism of the stainless steel.

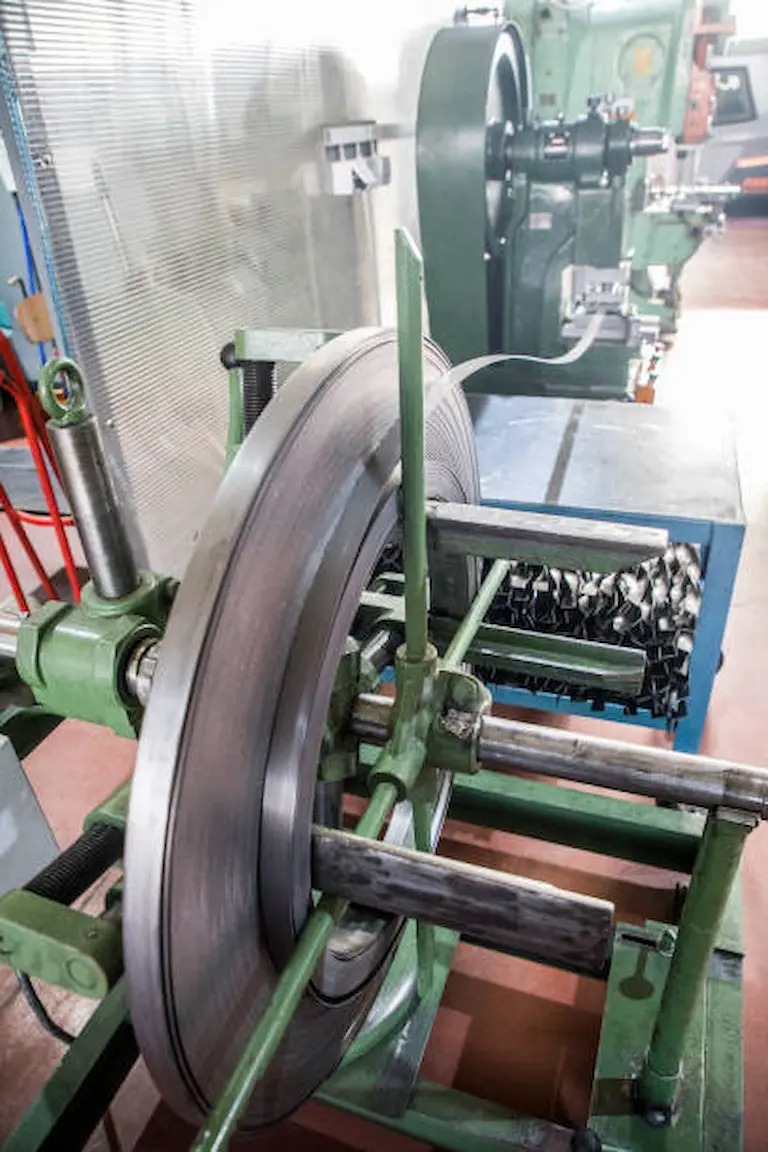

Yaoyi provides and produces type 301 stainless steel that is an austenitic chromium-nickel supplied in annealed and cold working conditions. Yaoyi’s type 301 provides the highest level of extensive formability in the annealed condition of every stainless steel and offers the maximum strength of any 300 series stainless steel in a heavily cold working condition. As a result of cold operations, our type 301 is non-magnetic but it can be magnetic in the annealed form.

Moreover, type 301 manufactured by Yaoyi is resistant to corrosion in several conditions but has weaker corrosion qualities than stainless steel 304/304L. Type 301 is restricted in some applications by its sensitivity to carbide precipitation during soldering, whereas 304L is employed due to its lower carbon concentration for soldered applications.

Uses of ASTM A240 Stainless Steel

Yaoyi is a premier stainless steel supplier who can provide you with the highest quality stainless steel from the 200 series and 300 series. Contact us today to learn more and get the free samples.

There are various stainless steel families and they each have different physical characteristics. A cheaper stainless steel would be a ferritic steel. Yaoyi’s ferritic stainless steels generally have greater technical features, yet they have poorer resistance to corrosion thanks to a lower nickel and chromium content than their cousin. This renders ferritic magnetic stainless steel.

In many situations in which thinner materials or decreased weight are needed, ferritic steels provide an advantage. The heat treatment is also not hardenable.

Consequently, typical applications for Yaoyi’s ferritic steel include exhaust systems for cars and trucks, converters for catalysts, agricultural spreaders, heat exchangers, culinary equipment and roofs.

In addition, classified in the 300 series are ferritic metals. We stock 301 stainless steel items and stainless steel products in Yaoyi.

Thin Stainless Steel Sheets Manufacturer

The more frequent forms of stainless in Yaoyi are austenitic stainless steels. The chromium and nickel percentage is higher in these grades. The increased nickel content is non-magnetic in austenitic grades.

Similarly, austenitic steels are not hardened by heat treatment but also possess superior formability and increased corrosion resistance.

Such types of steels are usually utilized in kitchen appliances, automobile trim, architectural, chemical, medicinal and many more applications ensured by Yaoyi Manufacturing Co.

The 200 and 300 series are categorized as austenitic stainless steels. We typically stock Yaoyi 301 items for stainless steel.

A little trivia, you should bring a magnet the next time you look for a refrigerator. Elevated quality stainless steel appliances and usually more expensive won’t set your magnet. But unfortunately, you will very probably get along with a ferritic stainless steel device unless you plan on putting your refrigerator out of it. After all, it remains stainless.

Magnetic response – or failure to do so – is often one of the first things people see as a fundamental attribute of stainless steel. The response of Yaoyi’s 301 stainless steel to a magnet is an intriguing physical phenomenon and can be a good sorting test.

Is 301 Stainless Steel Magnetic: What are the Magnetic Basic Properties?

Materials that are strongly attracted to a magnet whether permanent or electrical and can produce permanent magnets themselves. This is the usual attribute of a “magnetic” material.

The magnetic permissibility expresses the ease with which a magnetic material can be magnetised. Material is non-magnetic with values near to 1.0.

Is 301 Stainless Steel Magnetic: Hard or Soft Magnetic features

Magnets may be considered “Hard” or “Soft.” After exposure to a magnetic field, hard magnetic material has a high residual magnetism. A relatively tiny magnetic field is possible for soft magnetic materials and they return to low residual magnetism when this is removed.

As such, certain metals have a change in temperature from ferromagnetic to non-magnetic. This happens at around 768°C for standard carbon steels.

Coilover Springs: Characteristics, Materials, and Applications

All standard stainless steels including mild steel, low alloy steel and ferromagnetic tooling steels are available at Yaoyi. Some other metals are also ferromagnetic, such as nickel and cobalt. Every grade of steel, except the austenitic grade, all grades of duplex types, all grades of martensitic, and all grades of hardening precipitation are also magnetic. Even if the duplex grades contain austenite and ferrite mixtures, the magnet is still powerfully attracted.

Why do you need to buy YAOYI’s 316 stainless steel tube?

Most non-ferrous metals are non-magnetic, such as copper and alumina. The common 300 series (Cr-Ni) and the 200 series lower nickel (Cr-Mn-Ni) are both stainless austenitic stains, which are non-magnetic. Written austenitic stainless steel is typical to include extremely modest ferrite levels, yet this is not enough, especially in highly critical applications. magnetic performance.

Castings made from austenitic stainless steels have compositions that are slightly different from their worked equivalents. For example, the cast form of 316L is CF-3M. Most “austinic” cast alloys are made quite intentionally and feature a few percent ferrite – this prevents hot casting. A weld can be considered to be small, lengthy casting, and has roughly 4 – 8 percent ferrite for the same reason as the above austenitic solds.

Thus, the minimal amount of ferrite for soldering and casting results in little magnetic responsiveness, yet with a competent hand-held magnet it can be readily identified. This magnetic response can really be utilized with an appropriate “ferrite meter” to measure the ferrite amount in a weld. Special consumables are provided when a weld needs to be zero ferrite content.

On the other hand, ferrite-free plates can also be obtained, or a ferrite level confirmation test can be conducted on the existing 316 stock platform. “Ferrite free” items, not generally their magnetic characteristics, are especially made for a few specific corrosive circumstances.

The Best Stainless Steel Tube Supplier in China

Even if wrought austenitic steels are in the annealed condition non-magnetic, they can develop magnetic reaction while cold is working. Cold work can turn austenite into martensite.

As a result, this dramatically affects the strength of the traction and much more so on the power output. A highly cold 304 grade wire can generate a traction power of up to 2000 MPa. A particularly well wrought 304 will likewise be attracted to a magnet quite strongly.

Moreover, grades with larger levels of austenite-forming components – nickel, manganese, carbon, copper, and nitrogen – do not make it so magnetic when it works cold. This can be assessed as a ratio of previous austenite elements separated by former ferrite elements, or as a Ni/Cr ratio. Grade 316 goods are normally magnetic only, and 310 and 904L are practically completely non-magnetic, regardless of how cold the material is. Grade 301, on the other hand, has a lower level of nickel and work is harder than 304 and even after a short amount of cold work, it becomes strongly magnetic.

Everything You Need To Know:Stainless Steel Ties

Heat Treatment

A solution can be eliminated if the part of austenitic stainless steel has been produced in response to a magnet by cold work. The usual heating treatment at about 1050°C (depending on degrees) and the water quenching and other quick cooling can be followed. The high temperature causes the austenite “strain-induced martensite” to be reformed and the steel is re-magnetic. It has also become poor in strength.

Is 301 Stainless Steel Magnetic: What is the Response of Two Magnetic Materials?

There is no effect on other properties of the magnetic response. A magnet is attracted by the cold drawing 301 (and at less than a 316), but the resistance to corrosion is not affected. Some of the most corrosion-resistant stainless steels are the duplex, super-duplex and highly alloyed ferritic grades like 29-4C.

On the other hand, 301 also has high tensile strength, but that is not because of its magnetic response – due to the cold work, both its magnetic response and its high strength. Including MRI equipment and in naval mine-hunter vessels applications in which the lack of magnetic reaction may be necessary. For such purposes, specialist stainless steels assure low magnetic response can be sourced.

Always Provides You with the BEST Austenitic Stainless Steel Products

In electrical applications with a change in electromagnetic induction magnetically soft steels are used. Solenoids and relays are common examples and a ferritic stainless steel might also be a viable alternative for these components if they need corrosion resistance. Specialized ferritic bar grades with assured magnetic characteristics are available for essential applications subject to mill enquiry.

A piece of steel’s magnetic response is a fast and quality test that can be beneficial for classifying stainless steel grades.

Austenitic steels from other steels, including 300-series and 200-series. All other stones, including all ferritic, duplex, martensitic and precipitation stone stones, are attracted to a magnet. The austenitic 13 percent manganese (e.g. “P8”) are the only non-magnetic steels.

When a permanent magnet is placed near the steel, notice the response, if any.

It is notable that certain grades of austenitic stainless steel, particularly 301, are attracted to a magnet to some extent while cold, e.g. during bending, shaping, drawing or rolling. Due to cold work, stress relief in cherry-red heat will eliminate that response, but this stress relief will sensitize the steel and should not be conducted on an item to be utilized later in corrosive environments.

However, a whole ring is okay. While duplex grades are just half of the magnetic ferrite phase in comparison to fully ferritic grades like as 430, there is unlikely to be a sufficient ‘feel’ difference in the manual test to sort duplex steels of ferritic, martensitic or hardening grade precipitation grades.

Extentic rust and welds of stainless steel are generally also mildly magnetic, because a little proportion of ferrite has been deliberately included in an austenitic deposit. The percentage of ferrite is measured according to the quantities of magnetic response.

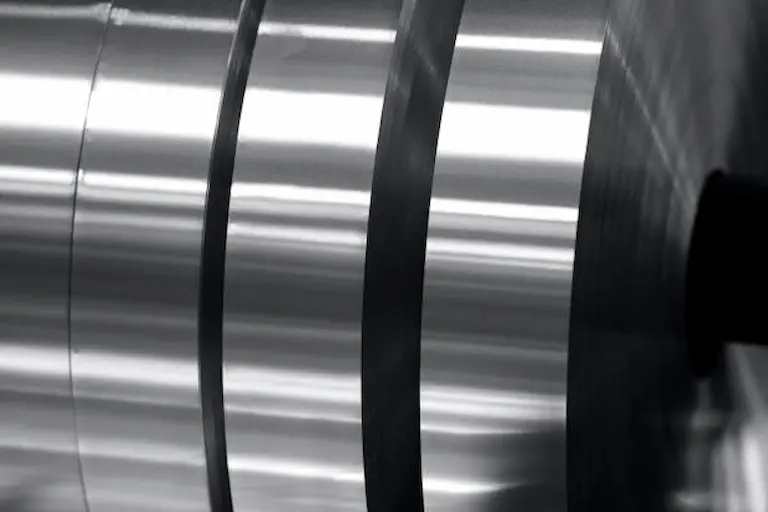

Your Best Supplier Of Stainless Steel Coil Always Provide You With SS Coil From China

One of Yaoyi’s chromium alloys creates magnetic grain structure in stainless steel. Nickel also decreases or inhibits magnetic characteristics as a possible alloy ingredient. In the 300 class of stainless steel, they are largely non-magnetic in various degrees of nickel. With no nickel and a carbon steel-like grain structure,

Slightly magnetic 400-series stainless steels are also available at Yaoyi.

Stainless Steel Belt: Characteristics, Advantages, and Applications

Yaoyi’s stainless steels have a ferritic grain structure, like carbon steel and are magnetic in their fundamental shapes. The addition of nickel to stainless steels in the 300 series changes the structure of crystal grain to austenitic. Due to its nickel content, austenitic grades are mainly not magnetised in an unworked state. When 300 series of stainless steels are cold worked, the magnet grain martensite develops a straining of the atomic lattice structure in areas of cold work.

In Yaoyi’s general procedures, the higher the nickel concentration, the stable the austenitic structure and the reduced cold-working magnetic response. Thus, in most circumstances, 316 stainless steel, with larger nickel levels, exhibits almost little magnetic strength after cold work. 304 can become moderately magnetic with a decreased nickel content.

Yaoyi’s Austenitic (300 series) magnetized stainless steels can be restored by annealing or stress relief to a non-magnetic state. The impacted grain structure reverses from martensitic condition to austenitic state after short heating at high temperatures. Because stainless steels of 400 series are completely ferritic or martensitic they can’t reduce their magnetic characteristics via ringing.

However, no finishing or placing operations, like passivation, can lessen the hardening of work induced magnetism. It is just superficial and does not alter the grain structure impacted.

Stainless Steel AISI 316Ti (S31635) By The AISI System

In air exposure, innovative steel, such as carbon steel, may rust. Chromium nevertheless in stainless steel generates a chromium oxide layer protective (also called passivation) to prevent iron oxide corrosion from developing. The layer of chromium oxide is so thin that the metal retains its appealing gloss.

The rustless stones of 300 series include higher chromium concentration than the rustless stones of 400 Series and nickel. Nickel improves the capacity of chromium to create a passive surface layer.

Thus, stainless steels from 300 series, especially type 301, have a greater resistance to corrosion. Corrosion resistance depends on the quantity of chromium and nickel and not the shape of metal grain that produces magnetism.

What is J4 Stainless Steel? (And What Is It Used For)

The answer is both yes and no. In its original state, 304 stainless steel is generally non-magnetic. However, this material can become slightly magnetic after cold working – such as pressing, bending, drawing, or rolling – due to a change in the microstructure of the metal that allows some magnetic properties to develop.

Alloy steel, which is a type of steel mixed with other elements such as nickel, vanadium, silicon, and boron, can be magnetic. The magnetic properties depend heavily on the specific elements used in the alloy, the amounts of those elements, and the process of how the alloy is made.

Yes, carbon steel is magnetic. Carbon steel is an alloy made up of about 99% iron, with a small amount of carbon. Due to its iron content, it is highly magnetic.

Non-magnetic stainless steel usually refers to austenitic stainless steel, such as 304 and 316. Austenitic stainless steels have a high chromium and nickel content that makes them non-magnetic in their annealed state. However, they can become slightly magnetic when cold worked.

High carbon steel, which is an alloy that contains a higher amount of carbon than other types of steel, is magnetic due to its significant iron content. Its magnetic properties can be enhanced based on the heat treatment and working process.

Yes, low carbon steel is magnetic. This material, often referred to as mild steel, has a relatively low concentration of carbon but is primarily composed of iron. Iron is a ferromagnetic material, which means it is attracted to magnets and can become magnetized itself.

Magnetic permeability is a measure of how easily a material can become magnetized when exposed to a magnetic field. Low carbon steel, also known as mild steel, has a high magnetic permeability because it is primarily composed of iron, a ferromagnetic material. This property makes low carbon steel a suitable material for many electrical and electronic applications.

Yes, pig iron is magnetic. Pig iron is one of the basic raw materials in the production of steel, and it has a high carbon content and contains significant amounts of iron, making it ferromagnetic.

Yes, chrome steel, also known as chromium steel, is magnetic. The iron in the steel makes it magnetic, and the chromium provides resistance to corrosion.