Myriad aisi 430 stainless steel has good corrosion resistance. Stainless steel added with stabilizing element titanium has good thermal conductivity and mechanical properties. yaoyi 430 stainless steel is used for architectural decoration, fuel burner parts, household appliances, and home appliance parts.

It is widely used in architectural decoration, household appliances, kitchen appliances, and industrial facilities. As the applications of 430 ferritic stainless steel continue to expand, the quality requirements, especially the surface quality, are becoming more demanding. This article will delve into the common issues related to 430 stainless steel, providing answers to frequently asked questions and offering insights into its properties, uses, and challenges.

So, what is the meaning of AISI? The very popular abbreviation that sits beside the name of a steel grade.

AISI means American Iron and Steel Institute. This organization was founded back in 1908 and is known for the contribution of standardizing the numbering system for steel together with the conjoined effort of the Society of Automotive Engineering.

Below is where you will find the common classifications consumers use to determine what steel grade they wish to purchase.

Austenitic steel is the most common classification because it has more purchases compared to the other stainless steel classifications in the market. Mainly because of its high corrosion resistance.

Austenitic steel contains high amounts of Chromium and Nickel and they are not hardenable by heat or heat treatment.

Martensitic steel is a classification of steel that contains a higher amount of carbon compared to austenitic stainless steel grades. This results in lower corrosion resistance in return for a much higher hardenability.

Another matter that is worth mentioning is that there is also a risk in chromium carbide precipitation in the process of its welding due to its components.

Ferritic stainless steel is known to be magnetic. Although there is a lot of magnetic austenitic steel as well, the ferrtic’s magnetic properties are just stronger. Its molecular grain structure and chemical composition differs greatly to other steel grades as well.

Meaning, it has its unique applications that other classifications cannot withstand.

Stainless Steel Cable Ties – YAOYI Stainless Steel

Now that you have gone through the fundamentals, it is time to get to know what AISI 430 is.

AISI 430 is stainless steel that is non-hardenable. Its uniqueness comes from its chemical composition, which is the absence of Nickel.

Nickel is a common element among other types of steel grades. So, what does this do to the 430 Stainless Steel? This steel grade may not have any nickel content but it does have molybdenum. It has good corrosion resistance and it has great formability.

Stainless Steel Chemical Composition – YAOYI Stainless Steel

AISI 430 still has corrosion resistance despite its absence of nickel, this is because chromium is majorly responsible for corrosion resistance protection. It does not have the best protection compared to other steel grades, but it is average.

When it comes to formability and ductility, it is also presentable as well. A key feature it has is its excellent resistance to nitric attacks, which makes it suitable to be around chemically exposed environments.

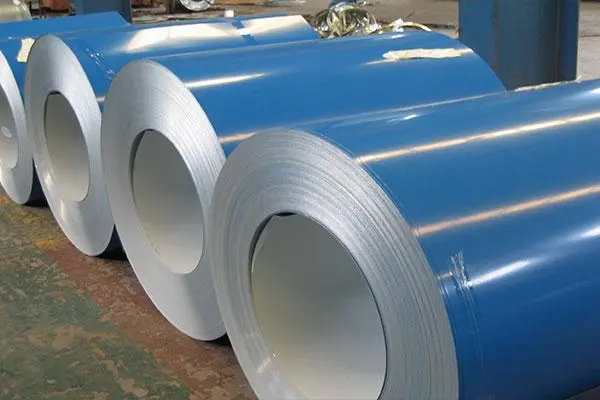

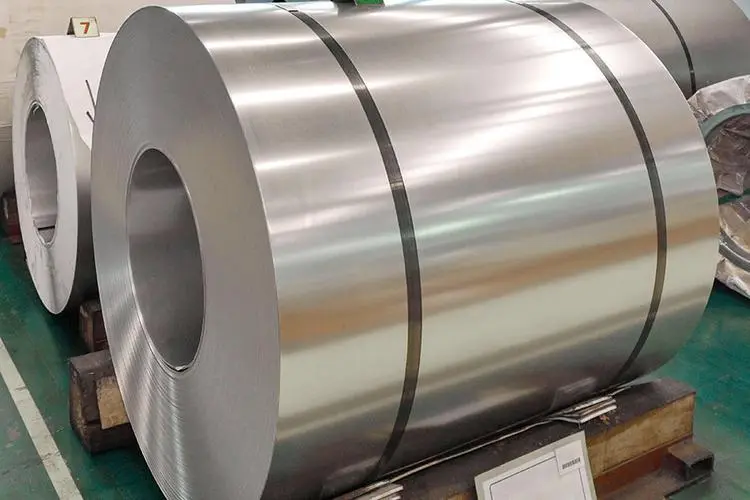

Stainless steel coil with high-quality and low-MOQ is provided in China.

As aforementioned, the unique characteristic of the 430 ss is its lack of nickel. It is still safe for food applications. In fact, AISI 430 can be used for grills due to its excellent resistance to heat and acid.

However, it is more vulnerable to corrosion but only for a long period of exposure.

The stainless steel foil provided in China with high quality and best price.

To better understand why the 430 Stainless Steel is capable of many applications and why it is resistant to various elements, learning its mechanical properties is the best way to cognize its attributes.

If you want to compare AISI 430’s mechanical properties to other steel grades, here is YAOYI’s Mechanical Properties Table.

Tensile strength is the resistance of steel being pulled apart. In other words, tensile strength refers to the resistance of steel breaking under tension.

The tensile strength of the AISI 430 is 79,800 psi (per square inch), which indicates that it is very strong steel.

Tensile strength refers to the tension resistance being pulled apart. In much simpler terms, it is the resistance of a certain material to breaking under tension.

Yield strength is associated with tensile strength because yield strength is the indication of how much stress steel can handle. It is measured the same way the tensile strength is.

The 430 Stainless Steel has a yield strength of 50,000 psi. It is capable of withstanding moderate amounts of stress.

Modulus of elasticity is different from elongation. MOE measures stiffness. It is equivalent to the stress being applied to the steel divided by the elastic strain. In comparison to rubber, steel has a much higher MOE.

In short, a stiff material has a high MOE. The 430 Stainless Steel, has a MOE of 29,000 psi. Suitable for projects that require stiff stainless steel.

Elongation is the measurement of steel of how much it can stretch from its original length. The measurement of elongation is rated through percentage. The higher the percentage, the more flexible the steel is.

The 430 Stainless Steel has an elongation rate of 25%, which means that it does not have the highest elongation rate compared to others but it does a pretty good job as it is.

Stainless Steel Rolls: Everything You Should Know – YAOYI Stainless Steel

When it comes to the chemical composition of the AISI 430, you will find the elements responsible for its protective layers.

Here is the Chemical composition of other steel grades from YAOYI’s CC Chart.

Below are the elements that the AISI 430 contains:

There is no nickel content on the AISI 430.

Stainless Steel 316 And 316L Graded By The AISI System

Because of its outstanding formability and ductility, the 430 Stainless Steel can be in various shapes and forms, such as the following:

A Complete Guide to 304 Stainless Steel Strapping

The AISI 430 has various applications and can be applied on different projects, but you must be cautious of where you are applying it as it can be weak in certain areas.

The AISI 430 can be used as the main material for sinks. Although not common, they are capable but not quite as corrosion-resistant to other steel grades. This makes it a cheaper option.

Since the AISI 430 is capable of withstanding nitric attacks, acid, and other chemicals, it is commonly used as a material for scientific apparatuses.

AISI 430 is good for refrigerators because of its heat resistance. Refrigerators require such heat resistance in order to keep the entire machine stable and to prevent it from overheating which is common among cheap refrigerators with cheap steel grades.

You won’t be surprised to see AISI 430 used on various industrial applications. This is because of their chemical withstanding properties that make them excellent mediums for industrial applications.

Once again, with its heat-resistant capabilities, you can often see AISI 430 stove rims because this steel will not melt on cooking temperatures at the stove.

A Manufacturer of Stainless Steel Strips

These two steel grades are often compared by consumers because of their similarities.

However, when it comes to price, the AISI 304 is more expensive due to its chemical composition and stronger protective elements. Mainly because of the presence of Nickel that contributes to its strong corrosion resistance.

The AISI 304 is also much easier to press and draw compared to the 430 Stainless Steel.

Always Provides You with the BEST Austenitic Stainless Steel Products

AISI 430 is an alloy stainless steel food grade metal which is very similar to the AISI 316. It has the same chromium content with the AISI 316 as well but the nickel content is far off. This makes it more affordable for food industries.

The alloy offers another advantage as well , which is the additional resistance against sulfur and oxidation.

ASTM A240 Material: Applications and Classifications

Yes, 430 Stainless Steel is safe for food since it is a food grade. There are other steel grades for this as well that are both suitable for food processing and serving. These could vary from the AISI 200 series and some of the steel grades in the AISI 300 series.

AISI 301 Chemical Composition: Characteristics, Compounds,and Grades

It has a low carbon and it is about 80% steel and it does have chromium, which makes it rust resistant. This is why it is used in low cost sinks and even tables. Home appliances as well from refrigerators, fryers, to certain kitchenware.

AISI 301 Equivalent: Components, Processing, and Applications

Below are the advantages and disadvantages of the 430 Stainless Steel. This section or part of the article will help you with your purchase decision as you go through the benefits and drawbacks of what this stainless steel offers.

Here are the key advantages of the AISI 430 stainless steel.

Without a doubt, the AISI 430 has good corrosion resistance and even nitric resistance. The 430 Stainless Steel is not afraid of other chemicals as well since it is designed to withstand such elements. With a highly polished surface, its corrosion resistance is optimal.

In terms of fabrication, the AISI 430 has a low work hardening rate which makes this stainless steel easy to bend and form. A low ductility rate makes it difficult to form. There are complications when it comes to cold work, but nonetheless, they can be processed.

AISI 430 stainless steel has superb heat resistance to oxidation in temperatures 870°C and even further. But when it comes to prolonged heating in temperatures ranging between 400-600°C, the stainless steel may encounter problems such as brittleness and cracking that require immediate annealing.

The 430 Stainless Steel as aforementioned, is cold workable but it is not just as ductile as the AISI 304. But nonetheless, its advantage is that the AISI 430 does not harden unlike the AISI 304 to the same extent.

For cheap stainless steel, its properties are very impressive when it comes to chemical resistance, not only that, as it can resist certain acids as well. This is the reason why it can be used for scientific apparatuses and chemical containers.

So, if you are looking for stainless steel that can survive chemically exposed environments without breaking the bank, then the AISI 430 is highly recommended.

Below are several disadvantages that you might encounter when working with AISI 430 stainless steel.

Unlike other steel grades, the AISI 430 cannot withstand temperatures that are just too high, it will show damage, cracks, and even melt at some point. This is one of the drawbacks of its cheap price.

The AISI 430 does have average ductility, but compared to the AISI 304, the difference is noticeable. The only advantage for the 430 Stainless Steel here is that it does not harden.

AISI 301 Properties: Characteristics, Compounds, and Applications

430 stainless steel, also known as ss430 or aisi430, is a medium chromium ferritic stainless steel. It is characterized by a low coefficient of linear expansion, thermal conductivity, strong resistance to chloride stress corrosion, and good cold working properties.

One of the key features of 430 stainless steel is its low coefficient of linear expansion. This means that it doesn’t expand or contract significantly with changes in temperature, making it an ideal material for applications where dimensional stability is crucial.

430 stainless steel exhibits good thermal conductivity. This property allows it to efficiently transfer heat, which is particularly beneficial in applications such as heat exchangers and heating elements.

Another notable feature of 430 stainless steel is its strong resistance to chloride stress corrosion. This makes it a suitable material for use in environments where it may be exposed to chloride ions, such as in marine applications or in the production of certain chemicals.

Finally, 430 stainless steel has excellent cold working properties. It can be easily formed and shaped at room temperature without losing its structural integrity, making it a versatile material for various manufacturing processes.

The production process of 430 stainless steel, also known as aisi 430 stainless steel or stainless 430, involves several stages, including iron production, three off, AOD, LF, continuous casting, furnace coil mill, hooded annealing furnace, hot annealing pickling line, twenty-roller mill, cold annealing pickling line, flattening machine, shearing unit, and finished product factory.

The production of 430 stainless steel begins with iron production, followed by a process known as “three off”. This initial stage sets the foundation for the production of the steel.

The next stages involve AOD (Argon Oxygen Decarburization), LF (Ladle Furnace), and continuous casting. These processes are crucial for refining the steel and shaping it into a usable form.

After casting, the steel is processed in a furnace coil mill and then annealed in a hooded furnace. Annealing is a heat treatment process that alters the physical and sometimes chemical properties of the steel to increase its ductility and reduce its hardness, making it more workable.

The steel then goes through a hot annealing pickling line, a twenty-roller mill, and a cold annealing pickling line. These processes further refine the steel and prepare it for the final stages of production.

Finally, the steel is processed through a flattening machine and a shearing unit before it reaches the finished product factory. At this stage, the 430 stainless steel is ready for distribution and use in various applications.

The production of 430 stainless steel, also known as 430f stainless steel or 1.4016 stainless steel, involves several challenges. These include controlling the atmosphere and furnace temperature in the hooded furnace, avoiding the reduction product water vapor stagnation on the coil surface, and increasing the amount of hydrogen replacement.

One of the main challenges in the production of 430 stainless steel is controlling the atmosphere and furnace temperature in the hooded furnace. This is crucial to avoid local high temperatures, which can lead to more serious oxidation.

Another challenge is avoiding the reduction product water vapor stagnation on the coil surface. This can lead to internal oxidation, which is the main reason for the surface roughness defects of cold-rolled sheets.

Increasing the amount of hydrogen replacement is also a challenge. This is necessary to ensure the timely and effective replacement of the reduction product water vapor, which can otherwise stay on the coil surface for a long time and lead to oxidation of the substrate.

Finally, dealing with internal oxidation is a significant challenge.

430 stainless steel, also known as ss 430 or 1.4016 material, is a medium chromium ferritic stainless steel that is widely used in architectural decoration, household appliances, kitchen appliances, and industrial facilities. It has a low coefficient of linear expansion, thermal conductivity, strong resistance to chloride stress corrosion, and good cold working properties.

One of the key properties of 430 stainless steel is its low coefficient of linear expansion. This means that it does not expand or contract significantly with changes in temperature, making it ideal for use in applications where stability and precision are important.

Another important property of 430 stainless steel is its thermal conductivity. This property allows it to efficiently transfer heat, making it useful in applications such as kitchen appliances and industrial facilities.

430 stainless steel is known for its strong resistance to chloride stress corrosion. This makes it highly durable and suitable for use in harsh environments where it may be exposed to corrosive substances.

Finally, 430 stainless steel has good cold working properties. This means that it can be easily formed and shaped at low temperatures without losing its strength or durability.

430 stainless steel, also known as 430 ss or 430 stainless steel magnetic, is widely used in various industries due to its excellent properties. Its applications include architectural decoration, household appliances, kitchen appliances, and industrial facilities.

Due to its aesthetic appeal and durability, 430 stainless steel is often used in architectural decoration. It can be used for both interior and exterior design elements, providing a modern and sleek look.

430 stainless steel is commonly used in the manufacture of household appliances. Its resistance to corrosion and heat makes it ideal for appliances such as refrigerators, dishwashers, and ovens.

In the kitchen, 430 stainless steel is used in the production of various appliances and utensils. Its resistance to heat and corrosion makes it suitable for cookware, cutlery, and kitchen sinks.

As the applications of 430 stainless steel, also known as ss 430 price per kg or ss430 material, continue to expand, the quality requirements of high-end customers on the product, especially the surface quality requirements are becoming more demanding. A steel mill in the production of thin specification SUS430 2B, some of the coil surface has serious roughness defects, affecting the color of the plate surface, can not fulfill the direct use of the original plate surface orders, resulting in product downgrading. In order to analyze the causes of the defects, the defective samples were tested and analyzed, and the causes of the defects were investigated and rectification plans were proposed.

In conclusion, 430 stainless steel, also known as type 430 stainless steel or stainless steel 430 price per kg, is a versatile and durable material with a wide range of applications. Its unique properties, such as its low coefficient of linear expansion, thermal conductivity, strong resistance to chloride stress corrosion, and good cold working properties, make it an ideal choice for various industries, including architectural decoration, household appliances, kitchen appliances, and industrial facilities.

For more information about 430 stainless steel and its applications, you can visit the following blogs:

Remember, the key to understanding 430 stainless steel is to understand its properties, production process, and applications. By doing so, you can make an informed decision about whether it’s the right material for your specific needs.