The stainless steel materials produced by yaoyi have been widely used and promoted in the manufacture of automobile assemblies and parts due to their excellent corrosion resistance, heat resistance, and good mechanical properties. With the development of automobile lightweight and the continuous improvement of the performance requirements of automobile anti-corrosion and high-temperature resistant parts, the types of parts made of stainless steel are increasing.

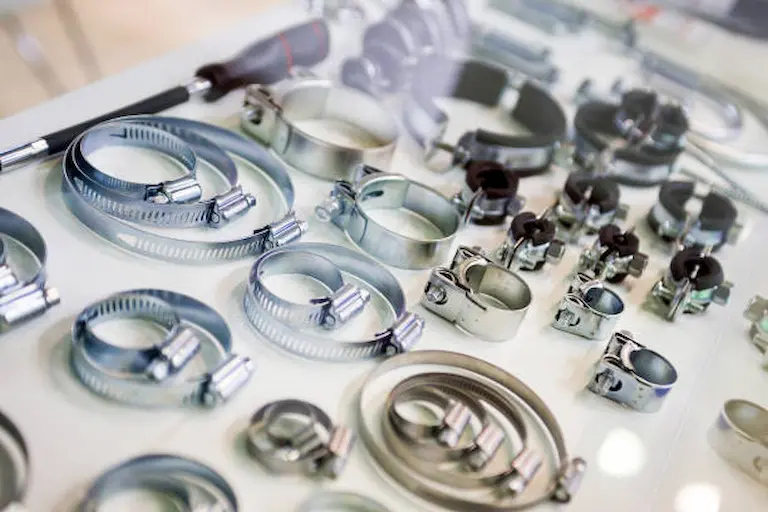

The stainless steel raw materials produced by Yaoyi are mainly used to produce seat belt connectors, clamps, wipers, bumpers, stainless steel seals, stainless steel heat exchangers, stainless steel tubing, and other auto parts.

SUS301 is widely used in the production of auto parts because of its excellent processing performance. Especially the clamp.

SUS304 is widely used in the production of auto parts because of its excellent corrosion resistance. Especially the fuel tank cap.

Stainless steel welded pipes are widely used in motorcycle exhaust pipes and other parts.

Besides the 0.05mm stainless steel foil, you may need to purchase other 304 stainless steel products from China, please contact us if you have any questions.

The materials for automobile body parts should generally have good rigidity and ductility, and it is required that no obvious spring back phenomenon should be produced during the stamping and forming process. Although stainless steel has good ductility, its resilience is very high, so it is not suitable for manufacturing body parts with complex forming structures.

Stainless steel materials can still be considered for the body coverings of some relatively simple rail transit vehicles and large passenger cars. Because the structural design and the excellent performance of the stainless steel material are well matched and integrated, the stainless steel frame manufactured is not only light in weight, good in impact resistance, but also safe, reliable, and long in life. Among them, SUH409L, 3Cr12, SUS304L, etc. are all commonly used stainless steel materials in the development of combined frames.

What is J4 Stainless Steel? (And What Is It Used For)

In addition to being widely used and researched in the manufacturing fields of exhaust systems, fuel tanks, car bodies, and frames, stainless steel materials also have certain applications in the manufacture of some typical auto parts, specifically involving stainless steel seals, heat 4 types of typical components such as oil pipes for exchangers, powertrain and transmission system accessories, and fasteners with special requirements for corrosion resistance.

Mainly aluminum alloy materials, but there are still some companies trying to produce stainless steel plate heat exchangers. The main materials used for powertrain and transmission system accessories include two types of double-layer coiled welded pipes and stainless steel seamless welded pipes. The main application areas involve brake pipes, fuel pipes, and various lubricating oil pipes.

For stainless steel fasteners, it is a supplement to traditional steel fasteners for cold heading and cold extrusion and is mainly used in areas with harsh environments and special requirements in engines and transmission systems.

|

Part |

Application of main materials |

|

Stainless steel sealing ring |

SUS301 |

|

Stainless steel heat exchanger |

SUS304、SUS430、SUH409L |

|

Stainless steel tubing for powertrain and transmission system |

SUS304 |

|

fastener |

SUS304、SUS316、SUS410、SUS430JIL、201 |

J3 Stainless Steel : A Complete Guide For Importers

To improve the overall appearance perception of users, some typical automotive decorative parts have been widely used in stainless steel materials, and have achieved standardization and standardization. Take a small car as an example.

Its door trim strips, welcome pedal trim strips, rear cover trim strips, fuel tank caps, seat belt tighteners, wiper branches, rearview mirrors, and exterior decorative bumpers are all widely used Stainless steel material; for large passenger cars and rail cars, its application areas mainly include safety guard bars, safety handrails, etc.

|

Type |

Part |

Application of main materials |

|

Car |

Door trim |

SUS 304、SUS 430 |

|

Rear cover decorative strip |

||

|

Pedal trim |

||

|

Fuel tank cap |

SUS 304 |

|

|

Seat belt tensioner |

SUS 301 |

|

|

Car wiper |

SUS 301、SUS 304 |

|

|

rearview mirror |

SUS 430J1L |

|

|

bumper |

SUS 304 |

|

|

Bus |

Security Fence |

SUS 304 |

|

Safety handrail |

SUS 304 |

J2 Stainless Steel: A Complete & Thorough Guide

The bellows assembly is located between the exhaust manifold and the catalytic converter. Its function is to relieve the vibration of the engine, have high-temperature fatigue resistance and corrosion resistance; its shape is corrugated, the common structure is three layers, and the corrugated wall thickness is 0.15 mm~0.2mm, in order from the inside to the outside: lined pipe (winding pipe), corrugated pipe and stainless steel mesh or belt.

Due to the need for controlled NVH performance in automobiles, mesh sleeves are designed on both sides of the bellows to avoid resonance between the bellows assembly and the exhaust system. Therefore, there are also 4 to 5 layers of bellows assemblies.

Because the corrugated pipe needs to be welded on a stainless steel pipe with a thickness of only 0.2mm and a large amount of bulging processing is required during the production, austenitic stainless steel is usually used. SUS304 is a commonly used material. If better durability is required For performance, SUS321 or SUS316Ti is recommended.

The traditional exhaust pipe flange is 8mm, 10mm thick Q235 steel, which is processed by casting. To improve the anti-corrosion performance, the non-machined surface requires blackening or dacromet treatment; now it can also be stamped with 3mm thick SUH409L steel plate. Finished, lightweight design, improved production efficiency, and improved anti-corrosion ability, no need for additional surface treatment.

The bracket used to assemble the rubber lugs on the exhaust pipe is made of a Q235 cylinder with a diameter of 10mm and 12mm. To improve the anti-corrosion performance, dacromet treatment is required; now it can be made of SUH409L steel pipe with the same diameter and 1.5mm thickness. Advantages of hollow steel pipe support: weight reduction, improved anti-corrosion performance, reducing dacromet treatment; hollow steel pipe heat dissipation is better than steel columns.

Stainless Steel Materials are an integral part of modern life, utilized across a myriad of industries and applications due to their unique properties. Understanding the intricacies of these materials, including their grades, composition, and uses, enables us to appreciate their extensive influence in our day-to-day life.

How To Find The Right Stainless Steel Supplier

Stainless Steel Materials are categorized into different grades, primarily austenitic, ferritic, martensitic, and duplex. Each grade is a unique combination of elements, rendering distinct properties and hence making them suitable for varied applications. For instance, austenitic stainless steel materials like 304 and 316 are renowned for their formability and corrosion resistance, which make them popular in kitchenware and chemical processing equipment.

The composition of Stainless Steel Materials is diverse and is tailored based on the desired properties. All stainless steel materials contain iron and at least 10.5% chromium, which forms a protective layer to prevent corrosion. Additional elements like nickel, molybdenum, and carbon are also included to enhance specific properties such as strength, heat resistance, and formability.

The multifaceted properties of Stainless Steel Materials make them indispensable in many industries. From kitchen appliances and medical instruments to construction structures and automotive parts, Stainless Steel Materials’ strength, durability, hygiene, and aesthetic appeal make them an ideal choice.

Stainless Steel Materials are revered for their corrosion resistance, high strength, heat resistance, hygiene, and aesthetic appeal. These properties are primarily due to the materials’ unique composition and can be enhanced or modified by altering the composition and manufacturing process.

The 304 grade is one of the most versatile Stainless Steel Materials, known for its excellent corrosion resistance and formability. It is an austenitic grade, composed of 18-20% chromium and 8-10.5% nickel, and is extensively used in applications ranging from kitchenware to chemical processing equipment.

The formula of Stainless Steel Materials is not fixed as it is an alloy composed of several elements. However, a basic stainless steel material like the 430 grade typically contains iron, chromium, and traces of nickel, carbon, manganese, silicon, phosphorus, and sulfur.

Stainless Steel Materials are composed of several elements that are found on the periodic table, including iron, chromium, and nickel. While the material itself does not occupy a specific location on the table , these constituent elements play a crucial role in determining the properties of various Stainless Steel Materials.

The processing of Stainless Steel Materials significantly influences their final properties. For instance, heat treatment can harden or soften the material, and cold working can increase its strength. The surface finish, whether it’s polished, brushed, or sandblasted, can also impact its aesthetic appeal and corrosion resistance.

Stainless Steel Materials generally exhibit excellent weldability, especially the austenitic grades. However, some types, such as martensitic and ferritic grades, may require pre or post-weld heat treatment to prevent cracking or retain their properties. Welding is a common method of joining stainless steel materials in many applications. However, the process can affect the properties of the material near the weld, known as the heat-affected zone.

Austenitic stainless steel materials, such as 304 and 316, are considered excellent for welding. They don’t require pre-heating, and they resist cracking, making them highly suitable for a variety of applications.

On the other hand, martensitic stainless steel materials, such as grades 410 and 420, have a high carbon content, which can lead to the formation of brittle martensite in the heat-affected zone during the welding process. Therefore, they often require preheating and post-weld heat treatment to maintain their mechanical properties and prevent cracking.

Similarly, ferritic stainless steel materials, such as grade 430, have good weldability but can become brittle in the heat-affected zone due to grain growth. Hence, a low heat input method is recommended for welding these materials.

Duplex stainless steel materials, which combine the characteristics of austenitic and ferritic grades, also have excellent weldability. However, maintaining the balance of austenite and ferrite phases in the weld and heat-affected zone is crucial to ensure the best combination of properties.

In conclusion, while stainless steel materials generally respond well to welding, the specific processes and precautions can vary based on the type of stainless steel material. Understanding these differences is crucial when manufacturing or repairing products made from these materials.