ASTM A167: Composition, Properties, and Equivalent Grades

Ewan Liao

ASTM A167 is a standard specification critical for austenitic stainless steel sheets, strips, and plates, defining material properties essential for industrial applications. This standard is particularly vital for materials like ASTM A167 Type 304 and Type 316, which offer exceptional corrosion resistance and mechanical performance. Understanding ASTM A167 and its material properties can guide manufacturers and engineers in selecting the right stainless steel for their needs.

Here’s the full explanation

Material Testing After You Place An Stainless Steel Foil Order

Hardness Testing

Ingredient detection

Tensile Strength Test

Table of Contents

What is ASTM A167?

ASTM A167 is a standard specification established by ASTM International for stainless and heat-resisting chromium-nickel steel plate, sheet, and strip. It provides detailed guidelines on material classification, chemical composition, mechanical properties, processing methods, heat treatment, and available finishes. The specification primarily applies to stainless steel products used in various industrial applications requiring corrosion resistance and strength.

In addition, the grades previously offered under Specification ASTM A167 have been removed from this specification, and grades from Specification A 240/A 240M are now offered and sold in accordance with Specification A 240/A 240M. When they were no longer part of Specification A167, the specifications for chemical and mechanical properties were identical for grades in Specification ASTM A167 and Specification A 240/A 240M.

A167 Type 302B is a specific type of A167 Stainless Steel.

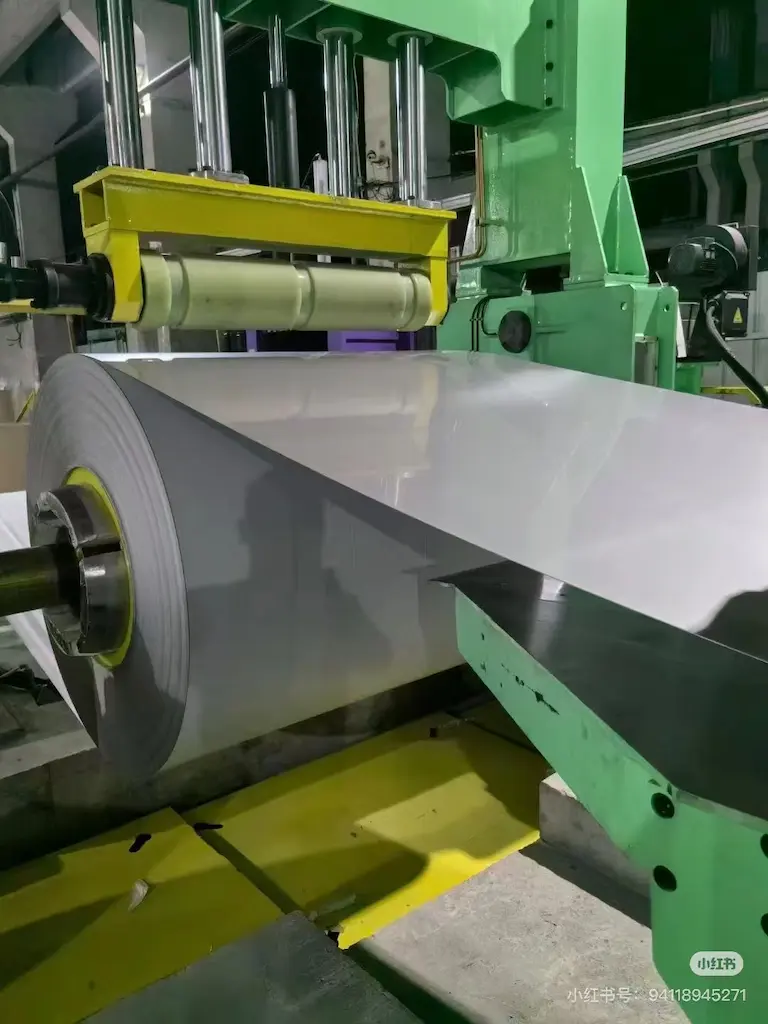

The thickness 0.1 mm~0.3 mm, width 550-600 mm cold rolled stainless steel coils are best selling.

Key Features of ASTM A167

1. Material Scope

- Plate: Material with thickness ≥ 3⁄16 in. (5.00 mm) and width > 10 in. (250 mm).

- Sheet: Material < 3⁄16 in. (5.00 mm) thick and width ≥ 24 in. (600 mm).

- Strip: Material < 3⁄16 in. (5.00 mm) thick and width < 24 in. (600 mm).

2. Chemical Composition

The specification outlines the maximum allowable limits for elements such as carbon, manganese, phosphorus, sulfur, silicon, chromium, and nickel. These vary by stainless steel grade (e.g., 302B, 308, 309, 310).

3. Mechanical Properties

Minimum tensile strength, yield strength, elongation, and hardness values are defined to ensure durability and performance.

- Tensile Strength: ≥ 75 ksi (515 MPa).

- Yield Strength: ≥ 30 ksi (205 MPa).

- Elongation: ≥ 40%.

4. Processing

Steel covered under ASTM A167 can be produced using electric-arc, electric-induction, or other suitable processes. Heat treatment is required to ensure compliance with specified mechanical properties.

5. Finishes

Various surface finishes are specified, ranging from polished (e.g., No. 4 or mirror finish No. 8) to dull finishes. These finishes cater to architectural, industrial, and other aesthetic or functional requirements.

6. Applications

Commonly used in industries like construction, chemical processing, and manufacturing, ASTM A167 materials are favored for their corrosion resistance, strength, and adaptability.

ASTM A167 Type 302B chemical composition

Stainless steel made from Type A167 contains these materials:

| UNS Designation | S30215 | S30800 | S30900 | S31000 |

| Type | 302B | 308 | 309 | 310 |

| Carbon,max | 0.15 | 0.08 | 0.2 | 0.25 |

| Manganese, max | 2 | 2 | 2 | 2 |

| Phosphorus, max | 0.045 | 0.045 | 0.045 | 0.045 |

| Sulfur, max | 0.03 | 0.03 | 0.03 | 0.03 |

| silicon,max | 3-Feb | 0.75 | 0.75 | 1.5 |

| chromium | 17-19 | 19-21 | 22-24 | 24-26 |

| nickel | 10-Aug | 12-Oct | 15-Dec | 19-22 |

| Nitrogen, max | 0.1 | … | … | … |

Carbon

Stainless steel made from Type A167 contains these materials:

Carbon with a minimum undetermined weight percentage of carbon and a maximum weight percentage of carbon. Carbon is a chemical element, the symbol for which is C, and has an atomic number of 6.

Silt

A silicon material with a minimum weight percentage of 2.00% and a maximum weight percentage of 3.00% It is a brittle, metallic, blue-gray solid with a bluish-gray luster and is a semiconductor and a metalloid of four valence. This is an unreactive compound.

Ferrous manganese

With an undetermined minimum weight percentage and a maximum weight percentage of 2.00, manganese can be described as an indeterminate alloy. Manganese is a chemical element with an atomic number of 25 and a symbol of Mn. However, sulfur is frequently found in minerals as part of an iron-sulfur compound. Manganese is a transition metal, which is primarily used in stainless steel alloys.

Phosphorus

0.045% total phosphorus weight The atomic number of phosphorus is 15, and its chemical symbol is P. The two basic elemental forms of elemental phosphorus, which are known as yellow phosphorus and white phosphorus, are not the only kinds. There is also a complex form of phosphorus known as red phosphorus.

Sulfur

0.03 maximum weight percentage of sulfur Sulfur, an element found in small amounts in all natural things, has an atomic number of 16 and is represented by the symbol S. It is readily found, proliferates rapidly, and is nonmetallic.

Chromium

17.0 weight percent and 19.0 weight percent of chromium. Chromium is a chemical element known as “Cr” and has an atomic number of 24. The first six elements are grouped together in Group 6. The color is dark gray with a metallic luster and a clear fracture. Also, chromium is a major additive in stainless steel, and it is also an anti-corrosive. Additionally, it is essential to remember that chromium is extremely valuable because it is a metal that can be polished to a very fine degree and that does not tarnish.

Chromium is used in steel for two reasons: the significant increase in corrosion resistance, and the strengthening effect of metal carbides found at grain boundaries. The chromium content is found between 3% and 5% in high-speed tool steels. Chromium is added to iron at a concentration of greater than 11% to produce stainless steel, the most common corrosion-resistant metal alloy. In order to form stainless steel, ferrochromium is added to molten iron while it is still hot.

Nickel

Nickel alloy containing a minimum percentage of 8% of total chemical weight and a maximum of 10% of total chemical weight. Nickel is a chemical element, which has the atomic number 28 and the symbol Ni. The color is silver-white with a hint of gold. Nickel is a ductile, hard metal that crosses the transition point from being soft to being hard.

Nickel is used in varying proportions, which are shown below: 68% in stainless steel; 10% in nonferrous alloys; 9% in electroplating; 7% in alloy steel; 3% in foundries; and 4% in other applications (including batteries).

In other words, the nickel used in industrial and consumer products includes many distinct and well-known goods such as stainless steel, alnico magnets, coinage, rechargeable batteries, electric guitar strings, microphone capsules, plumbing fixture plating, and more specialized alloys such as permalloy, elinvar, and invar.

A metal with excellent mechanical properties of ASTM A167 Type 302B

For this specific type of stainless steel, the proof of strength is equal to or greater than 598. Tensile strength of 937 and impact energy of 34 are among or equivalent to one another. The elongation at fracture of A 167 Type 302B is 22 millimeters. The cross section is reduced by 32 as the fracture heals. The reduction occurs as solution and aging, annealing, ausaging, Q + T, and many other conditions are applied.

J2 Stainless Steel: A Complete & Thorough Guide

Type 302B has physical properties of ASTM A167

Steel possesses a property greater than or equal to 291, with a density greater than or equal to 833. The specific heat of the A167 Type 302B Stainless Steel is 32, however, the temperature of the A167 Type 302B Stainless Steel is 43.

The approximate thermal conductivity of steel is 13. The electrical resistance consists of various elements such as solution, aging, annealing, and Q + T. Elasticity is at 332, and the modulus of elasticity.

This stainless steel was discovered to have a new temperature: 219 degrees. while the A167 Type 302B creep rupture strength is 455, the A167 Type 302 creep strain is 148.

J3 Stainless Steel : A Complete Guide For Importers

Consider the following grades: A167 type 302B

In terms of the specific stainless steel mentioned above, these are the possible grades to which the phrase may be equivalent:

1. CNS 302B

2. 302B

3. A 167 Type 302B

4. A 314 302B

5. A 276 302B

6. A 473 302B

7. A 580 Type 302B

8. A 959 Type 302B

9. SWS 302B

10. A 167 S30215

11. A 276 S30215

The grade believed to be most similar to A 276 is stainless steel.

The higher the grade of stainless steel, the better. Some experts claim that, in the vast majority of cases, there are five basic classifications of stainless steel: austenitic, ferritic, martensitic, duplex, and precipitation-hardening.

Additionally, the majority of stainless steels contain approximately 16-26% chromium and up to 35% nickel. The non heat-treatable, non-magnetic synthetic resin is in use in the molds. 304 stainless steel is an alloy of 18% chromium and 8% nickel, and it has a chromium/nickel ratio of 18/8. This type of application is found in a variety of industries, including aviation, food, and dairy manufacturing.

Chromium, which means low carbon, and they’re nickel-free because of their high chromium content (less than 0.2 percent ). The vast majority of the titanium used in our jewelry is not heat treated. We use it as architectural and automotive trim, and very occasionally for surgical implants. The most frequent chromium, carbon, and nickel concentrations are found in martensitic steels; a chromium content of 11.5 to 18 percent is common. Flexible and durable for tools, wrenches, and turbines. Ferritic and austenitic stainless steels are included in this mixture. The composition contains between 21% and 27% chromium, between 1.35% and 8% nickel, and between 0.05% and 3% copper, as well as between 0.05% and 5% molybdenum.

Ferritic stainless steels (in the building of storage tanks, chemical processing, and chemical containers) are both stronger and more resistant to corrosion than austenitic stainless steels (in storage tanks, chemical processing, and chemical containers).

Aluminum, copper, and niobium are added in concentrations that are less than half a percent of the alloy’s total mass. It has many of the same corrosion resistance properties as stainless steel, but it has chromium concentrations between 15% and 17.5%, nickel concentrations between 3% and 5%, and copper concentrations between 3% and 5%. A lengthy shaft is produced in precipitation-hardening stainless steel.

J4 stainless steel Food Grade : the best you can find & purchase.

A’s products can be translated as ASTM A167-type 302B-equivalent

Some of the most popular products produced were really efficient and widely used, with this ASTM 167 steel type include the following:

1. Tool Die Steels

2. Stainless Steels

3. Square and Flat Steel

4. Coil Sheet

5. Bar and Hollow Bar

6. Forging

7. Superalloy

8. Tube Pipe

9. Non-Magnetic Steel

10. Steels of Blade for Steam Turbine

Stainless Steel AISI 316Ti (S31635) By The AISI System

Need more infomation about the materials?

With fierce market competition, various companies have increasingly higher requirements for raw materials. Suppliers that can provide high-quality products, reliable credit, and complete services are important factors that constitute a stable supply chain, and everyone is striving to find them.

For us, 25 years of manufacturing experience means that we have the ability to serve customers from all over the world, to provide the best stainless steel products, and in fact we are doing the same. Therefore, when you have any questions about the product, the best way is to get in touch with us.

The cooperation between us will start with free high-quality samples.