| Brand | Location | Main Products | Link |

|---|---|---|---|

| Outokumpu | Finland | Stainless steel products, including coils and foils | |

| ATI | USA | High-performance metals, including stainless steel foils | |

| Sandvik | Sweden | Stainless steel foils and alloys | |

| AK Steel | USA | Steel products, including stainless foils | |

| Thyssenkrupp | Germany | Diverse steel products, including stainless foils | |

| Jindal Stainless | India | Stainless steel flat products | |

| Nippon Steel | Japan | Stainless steel materials, including foils | |

| Hamilton Precision Metals | USA | Precision metal strips and foils | |

| All Foils | USA | Metal foils, including stainless steel | |

| Yaoyi Stainless Steel | China | High-quality stainless steel foils and coils |

When it comes to stainless steel foil, one of the key considerations is the cost. Understanding the pricing factors and variations can help you make informed decisions. In this article, we will explore the prices of stainless steel foil, focusing on the types, thicknesses, and associated costs.

Stainless steel foil is available in various types, each with its unique properties and applications. Let’s take a look at some commonly used types:

304 Stainless Steel Foil: This type of stainless steel foil is widely used due to its excellent corrosion resistance and versatility. It finds applications in industries such as food processing, automotive, and construction.

316 Stainless Steel Foil: Known for its superior corrosion resistance, 316 stainless steel foil is commonly used in marine environments and chemical processing industries. It offers resistance against pitting and crevice corrosion.

321 Stainless Steel Foil: With its high-temperature resistance and excellent weldability, 321 stainless steel foil is suitable for applications involving elevated temperatures. It is commonly used in aerospace, power generation, and exhaust systems.

347 Stainless Steel Foil: This type of stainless steel foil offers improved high-temperature strength and resistance to intergranular corrosion. It is commonly used in applications where high-temperature stability is required.

Several factors influence the prices of stainless steel foil. Understanding these factors can help you assess the cost breakdown. Here are the key factors to consider:

Type of Stainless Steel: Different types of stainless steel have varying compositions and properties, which can affect the production cost and, subsequently, the price of the foil.

Thickness of the Foil: The thickness of the stainless steel foil plays a significant role in determining its price. Thicker foils require more raw material and additional processing, leading to higher production costs.

Supplier and Location: The supplier and location from which you purchase the stainless steel foil can impact the price. Factors such as transportation costs, import/export duties, and local market conditions can vary, affecting the overall cost.

Market Demand and Availability: The demand for stainless steel foil and its availability in the market can influence the prices. If the demand is high and the supply is limited, the prices may increase due to market dynamics.

Let’s delve into the prices of stainless steel foil for different types and thicknesses:

| Type | Thickness | Price |

|---|---|---|

| 304 Stainless Steel Foil | 0.002″ | $50 per pound (36″ x 200′ roll) |

| 304 Stainless Steel Foil | 0.002″ | $437.71 each (24″ x 50′ roll in a package of 2) |

| 316 Stainless Steel Foil | 0.005″ | Price not directly available (24″ x 1200″ sheet) |

| 316 Stainless Steel Foil | 0.01″ | $20 to $35 per kilogram (30mm wide roll with customizable thickness up to 2mm) |

“The price of stainless steel foil depends on various factors such as the type, thickness, and the supplier’s pricing strategy.” – Anonymous Industry Expert

In conclusion, the cost of stainless steel foil depends on factors such as the type of stainless steel, thickness of the foil, supplier, and market dynamics. Understanding these factors can help you make informed decisions when purchasing stainless steel foil.

Always consider your specific requirements and budget when selecting the type and thickness of stainless steel foil. Additionally, stay updated with the latest prices from your supplier, as they may vary.

For more information and detailed pricing, reach out to trusted suppliers or visit their websites. By understanding the cost breakdown of stainless steel foil, you can make well-informed decisions and ensure that you get the best value for your investment.

Stainless steel foil is versatile. It’s used in automotive, aerospace, and even in medical equipment. Its resistance to high temperatures and corrosion makes it ideal for these applications.

Outokumpu is the top stainless foil manufacturer in Finland.

| Element | Composition (%) |

|---|---|

| Chromium | 18-20 |

| Nickel | 8-10.5 |

ATI is the top stainless foil manufacturer in the USA.

| Element | Composition (%) |

|---|---|

| Chromium | 16-18 |

| Nickel | 10-14 |

| Molybdenum | 2-3 |

Sandvik is the top stainless foil manufacturer in Sweden.

| Element | Composition (%) |

|---|---|

| Chromium | 22-24 |

| Nickel | 12-15 |

AK Steel is the top stainless foil manufacturer in the USA.

| Element | Composition (%) |

|---|---|

| Chromium | 17-19 |

| Nickel | 9-12 |

| Titanium | 5 |

Thickness varies. For instance, Yaoyi Stainless Steel offers foils ranging from 0.01mm to 0.6mm. Choose based on your needs.

How thick is 304 stainless steel foil?

304 stainless steel foil commonly ranges from 0.01mm to 0.6mm in thickness.

Stainless foil isn’t just a shiny sheet; it’s a powerhouse.

Stainless foil laughs in the face of rust. Its alloy composition ensures it stays fresh and untarnished.

Your average foil might wilt under heat, but not stainless foil. Its melting point is sky-high, making it a go-to for high-heat applications.

From car parts to cooking, stainless foil’s got you covered. It’s versatile, reliable, and always up for a challenge.

This isn’t your grandma’s foil. Stainless foil is robust and long-lasting, designed to withstand tough conditions.

In the realm of aluminum, heavy-duty foil typically ranges from 0.016 to 0.024 mm. However, stainless steel foil can go as thin as 0.01mm!

What is the difference between aluminum foil and heavy-duty aluminum foil?

Heavy-duty aluminum foil is thicker and stronger. Stainless steel foil, though, takes the cake for strength and heat resistance.

Making the right choice isn’t always easy, but when it comes to stainless foil, Thyssenkrupp is your German go-to.

What’s the end game? If you’re in aerospace, you’ll want something heat resistant. For marine uses, corrosion resistance is key.

Check the melting point. If you’re going into a furnace, you’ll need something that can take the heat.

Not all foils are created equal. Make sure the alloy fits your corrosion needs.

Some foils are easier to work with than others. If you’re going to be cutting or shaping, consider this factor.

Yes, steel foil exists, but stainless steel foil is more corrosion-resistant and ideal for specialized applications.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Stainless foil, commonly known as stainless steel foil, is a thin sheet of stainless steel. It is a versatile material extensively used in various industries due to its exceptional features. High resistance to corrosion, excellent strength-to-weight ratio, and durability are some of the defining properties of stainless foil.

The aerospace industry often employs this material in aircraft construction, owing to its high strength and lightness. Medical device manufacturers also favor stainless foil because it’s non-toxic and resistant to biological contamination.

In the electronics industry, the foil serves as an excellent conductor for high-speed data transfer and electrical currents. It can withstand high temperatures, making it ideal for use in electrical insulation and heat shielding.

Stainless foil’s high-temperature resistance also lends itself well to the automotive industry, where it’s used in exhaust systems and turbocharger insulations. In the construction industry, it is used for roofing, siding, and window frames, adding to the building’s durability and aesthetic appeal.

Furthermore, stainless foil is also useful in home kitchens for cooking and baking purposes, as well as in artistic applications for its aesthetic appeal.

Stainless steel foil for cooking is a practical choice due to its several advantages. First and foremost, it is non-toxic and food safe, posing no health risks when used for food preparation or storage.

It is heat-resistant and flame-resistant, providing an excellent protective barrier for food when cooking at high temperatures. The foil can also be used as a liner to keep ovens, grills, and pans clean by capturing drips and spills.

This SS foil retains heat efficiently, which helps to cook food evenly. It can also be used to cover dishes and lock in heat, keeping food warm for a longer period.

Despite its thinness, stainless steel foil is quite durable. It won’t easily rip or tear, even when used with sharp-edged food items.

Another major advantage is its recyclability. Stainless steel foil can be reused after a simple cleaning, contributing to sustainability and reducing household waste.

A feature that many cooks appreciate is that stainless steel foil doesn’t interfere with the taste of food. Unlike some other materials, it doesn’t leach into food during cooking.

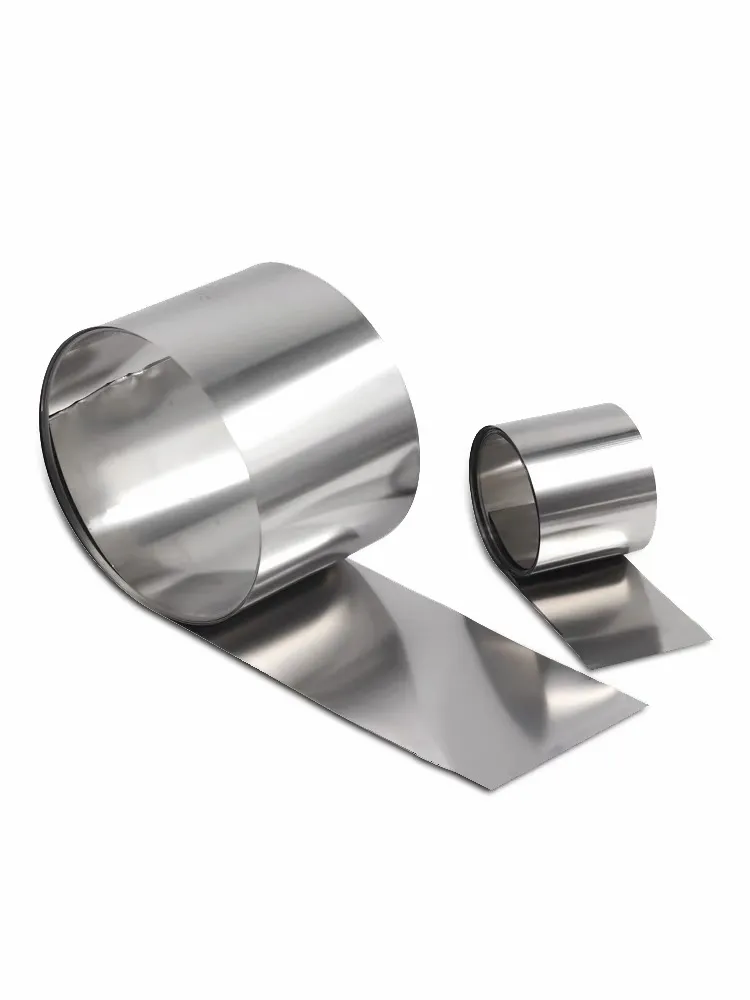

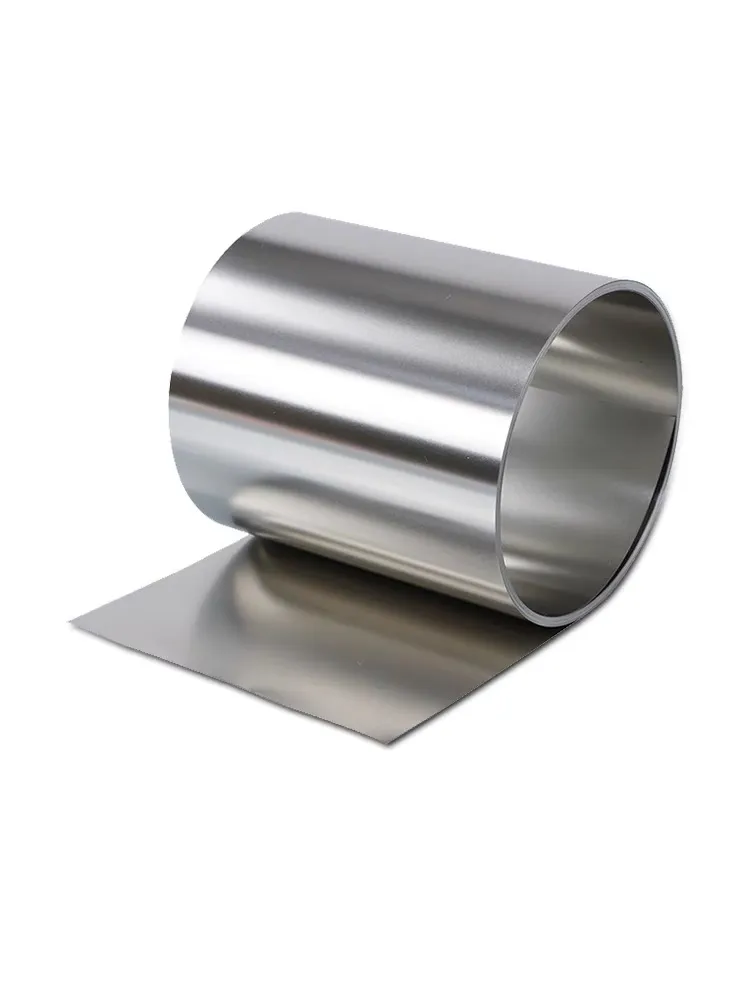

A stainless steel foil roll is simply a roll of stainless foil, offering convenience and versatility for various applications. Like all stainless foil, it offers excellent corrosion resistance, high-temperature resistance, and impressive strength-to-weight ratio.

A key characteristic of stainless steel foil roll is its flexibility. It can be easily cut, bent, and shaped to fit the desired application, making it a favorite among many industries.

These foil rolls come in various thicknesses, widths, and lengths, allowing for customization according to specific needs. From ultra-thin for delicate applications to thicker variants for heavy-duty tasks, stainless steel foil rolls cater to a vast range of requirements.

In terms of composition, stainless steel foil rolls often come in different grades. Each grade has a unique alloy composition that affects its properties, such as hardness, durability, and resistance to certain types of corrosion.

The surface of a stainless steel foil roll can be either shiny or matte, depending on the finishing process. This gives users a choice based on their aesthetic or practical requirements.

Stainless steel foil tape is a unique type of stainless foil that comes with an adhesive backing. This feature allows for quick and easy application in various scenarios, eliminating the need for fasteners or welding.

This type of tape is particularly useful in the HVAC industry, where it is used to seal and join ductwork, improving system efficiency. It’s also used for shielding and grounding in electronics, owing to its excellent conductivity.

The adhesive used in stainless steel foil tape is usually pressure-sensitive, which means it adheres more strongly when pressure is applied. It also often possesses high-temperature resistance, making it suitable for use in environments that experience significant heat fluctuations.

Stainless steel foil tape is also used for its reflective properties. In industries where heat and light reflection is crucial, this tape serves as a beneficial tool. For instance, it is used in lighting fixtures to enhance illumination.

Despite its adhesive backing, stainless steel foil tape can be removed without leaving a sticky residue. This makes it a convenient option for temporary fixes or applications where cleanliness is a priority.

316 stainless steel foil stands out among various stainless steel foils due to its enhanced corrosion resistance. This is primarily due to the addition of molybdenum, an element that significantly enhances resistance to chlorides.

This type of stainless foil is particularly useful in environments exposed to saltwater or corrosive chemicals. Hence, it’s a common choice in marine applications, chemical processing plants, and pharmaceutical production.

In addition to its high resistance to corrosion, 316 stainless steel foil possesses excellent formability and weldability. This makes it easier to shape and join, thus increasing its versatility.

Like other stainless steel foils, 316 stainless steel foil is also resistant to high temperatures, making it suitable for heat-intensive applications. However, it also remains stable at cryogenic temperatures, a property that sets it apart from many other stainless steel grades.

This foil is also known for its aesthetic qualities. It can be polished to a high shine, making it suitable for decorative applications. However, it can also be finished in a variety of ways to meet specific visual or functional requirements.

Steel foil sheets, also known as stainless steel foil sheets, offer many of the same properties as other forms of stainless steel, such as bars, rods, and plates. However, their unique format lends them to some specific applications.

As a thin sheet of stainless steel, steel foil sheet is flexible and can be cut and formed easily. This makes it perfect for applications that require precise shaping, like in electronics, where it’s used for making connectors, and in automotive, where it’s employed for heat shields and exhaust systems.

Steel foil sheets also provide an excellent surface for printing, making them ideal for producing nameplates, labels, and decorative items. They can also be used in artistic applications, given their malleability and reflective surface.

Despite their thinness, steel foil sheets retain the core characteristics of stainless steel, including high-temperature resistance and corrosion resistance. This means they can be used in environments that are both high in temperature and corrosive.

On the other hand, other forms of stainless steel such as bars, rods, or plates, due to their greater thickness, are generally more suitable for structural applications where high strength and rigidity are required.

Titanium foil and stainless foil, though both are metallic foils, have several differences due to their unique material properties.

Titanium foil is known for its remarkable strength-to-weight ratio, exceeding that of stainless steel. This property makes it particularly attractive in industries such as aerospace, where weight reduction is critical.

Titanium foil is also highly resistant to corrosion, even in environments such as saltwater that can be highly corrosive to stainless steel. Furthermore, titanium is bio-compatible, making its foil an excellent choice for medical applications such as implants and surgical instruments.

However, despite its impressive properties, titanium foil is significantly more expensive than stainless foil, which can limit its use in cost-sensitive applications. It is also less readily available and more challenging to manufacture.

In contrast, stainless foil is much more affordable and widely used. Its properties, such as excellent corrosion resistance, high-temperature tolerance, and good strength-to-weight ratio, make it suitable for a wide range of applications. Furthermore, the availability of different grades of stainless steel allows for customization based on specific needs.

316 stainless steel foil stands out among various stainless steel foils due to its enhanced corrosion resistance. This is primarily due to the addition of molybdenum, an element that significantly enhances resistance to chlorides.

This type of stainless foil is particularly useful in environments exposed to saltwater or corrosive chemicals. Hence, it’s a common choice in marine applications, chemical processing plants, and pharmaceutical production.

In addition to its high resistance to corrosion, 316 stainless steel foil possesses excellent formability and weldability. This makes it easier to shape and join, thus increasing its versatility.

Like other stainless steel foils, 316 stainless steel foil is also resistant to high temperatures, making it suitable for heat-intensive applications. However, it also remains stable at cryogenic temperatures, a property that sets it apart from many other stainless steel grades.

This foil is also known for its aesthetic qualities. It can be polished to a high shine, making it suitable for decorative applications. However, it can also be finished in a variety of ways to meet specific visual or functional requirements.

Steel foil sheets, also known as stainless steel foil sheets, offer many of the same properties as other forms of stainless steel, such as bars, rods, and plates. However, their unique format lends them to some specific applications.

As a thin sheet of stainless steel, steel foil sheet is flexible and can be cut and formed easily. This makes it perfect for applications that require precise shaping, like in electronics, where it’s used for making connectors, and in automotive, where it’s employed for heat shields and exhaust systems.

Steel foil sheets also provide an excellent surface for printing, making them ideal for producing nameplates, labels, and decorative items. They can also be used in artistic applications, given their malleability and reflective surface.

Despite their thinness, steel foil sheets retain the core characteristics of stainless steel, including high-temperature resistance and corrosion resistance. This means they can be used in environments that are both high in temperature and corrosive.

On the other hand, other forms of stainless steel such as bars, rods, or plates, due to their greater thickness, are generally more suitable for structural applications where high strength and rigidity are required.

Titanium foil and stainless foil, though both are metallic foils, have several differences due to their unique material properties.

Titanium foil is known for its remarkable strength-to-weight ratio, exceeding that of stainless steel. This property makes it particularly attractive in industries such as aerospace, where weight reduction is critical.

Titanium foil is also highly resistant to corrosion, even in environments such as saltwater that can be highly corrosive to stainless steel. Furthermore, titanium is bio-compatible, making its foil an excellent choice for medical applications such as implants and surgical instruments.

However, despite its impressive properties, titanium foil is significantly more expensive than stainless foil, which can limit its use in cost-sensitive applications. It is also less readily available and more challenging to manufacture.

In contrast, stainless foil is much more affordable and widely used. Its properties, such as excellent corrosion resistance, high-temperature tolerance, and good strength-to-weight ratio, make it suitable for a wide range of applications. Furthermore, the availability of different grades of stainless steel allows for customization based on specific needs.

Introduction: Stainless foil is widely used in industries due to its versatility. Stainless Steel Foil Sheets and Rolls have distinct applications, making them essential in different fields.

Uses of Stainless Foil: Stainless foil serves in electronics, construction, automotive, and more. Its high resistance to corrosion and flexibility makes it irreplaceable.

Stainless Steel Foil Sheets: These are popular in decorative purposes and food packaging. Stainless steel foil for cooking is also a significant application.

Stainless Steel Foil Roll: Ideal for industrial applications, this form is easy to handle and transport.

Comparison: Table 1 outlines the differences between stainless foil, sheets, and roll.

| Type | Application | Thickness |

|---|---|---|

| Foil | Electronics | 0.01mm |

| Sheets | Packaging | 0.05mm |

| Roll | Industrial | Varies |

Quality Considerations: Choosing the right thickness and grade (e.g., 304 stainless foil) is vital.

Environmental Impact: Sustainable manufacturing practices are increasingly becoming critical.

Safety Measures: Proper handling and storage of stainless foil are essential to ensure safety.

Future Trends: Advances in technology are continuously shaping the utilization of stainless foil.

Conclusion: Understanding the different forms of stainless foil and their applications can guide informed decisions.

Introduction: Comparing 304 stainless foil with 316 stainless foil helps in understanding their applications.

304 Stainless Foil: Known for its excellent corrosion resistance, it’s used in various applications, including stainless steel foil for cooking.

316 Stainless Foil: This grade contains molybdenum, enhancing resistance to chlorides. Suitable for marine applications.

Key Differences: The primary difference lies in chemical composition, as illustrated in Table 2:

| Grade | Chromium | Nickel | Molybdenum |

|---|---|---|---|

| 304 | 18-20% | 8-10% | 0% |

| 316 | 16-18% | 10-12% | 2-3% |

Price Considerations: 316 tends to be more expensive due to the presence of molybdenum.

Application Specifics: Choosing between the two depends on specific needs like corrosion resistance or affordability.

Quality Testing: Rigorous testing ensures that the desired grade meets standards.

Maintenance and Care: Both grades require proper maintenance to preserve their attributes.

Future Trends: Innovation in manufacturing could lead to new grades with enhanced features.

Conclusion: Recognizing the differences between 304 and 316 stainless foil is vital for selecting the right material.

Stainless steel foil is often used in the manufacturing of wire braided hoses due to its durability, corrosion resistance, and flexibility. Here’s how stainless steel foil is integrated into these hoses:

By integrating stainless steel foil into wire braided hoses, manufacturers create products that combine the flexibility needed for handling and installation with the strength and durability required for industrial applications. The result is a high-performance hose that can endure challenging environments, resist corrosion, and maintain structural integrity under high pressures and temperatures.