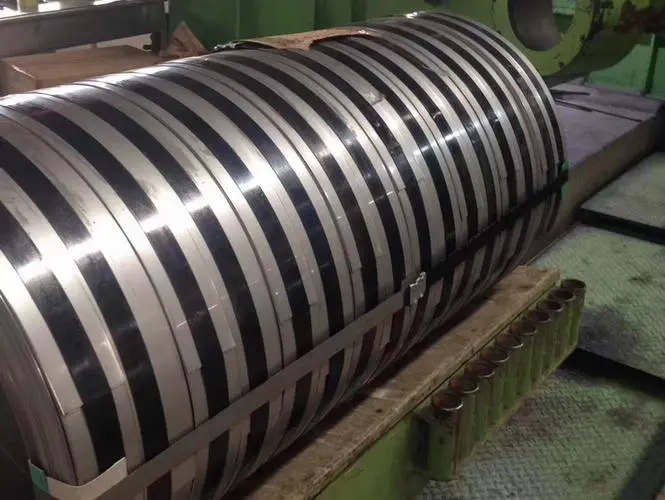

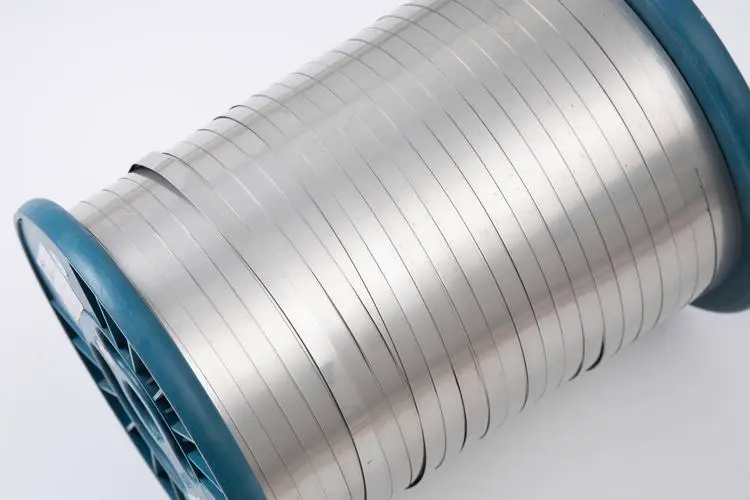

As humans have found different ways to build, they have also developed other elements throughout the years. Technology has helped refine and improve the quality of materials used in construction or other projects. Wood, steel, concrete, and many others have different attributes that would fit various purposes. The Aisi 321 stainless steel coil has many forms, including coils, pipes and plates. . . .

Stainless steel has been one of the most versatile materials. It can be used indoor, outdoor, in kitchens, hospitals, restaurants, pantries, operating rooms, and many more. It can also be bought in bulk or small quantities for commercial and household needs.

AISI stainless steel or Stainless 321 is a kind of steel that has improved intergranular-corrosion resistance. It is a mix of chromium and nickel steel. It is very sturdy and can resist many agents such as atmospheric corrosion, robust solutions, and different chemicals.

This particular variant of stainless steel is from the austenitic family, which is recognized for its excellent ductility, elevated temperature properties, and good resistance to many corrosive environments. AISI 321 is stabilized against chromium carbide formation by the addition of titanium, which is introduced in the steel composition during the melting process. This makes it particularly suitable for applications within the 430-900°C temperature range where other types of stainless steel, such as 304, would be prone to intergranular corrosion.

As mentioned, stainless steel has standards that it is graded. The SAE or the Society of Automotive Engineers uses digits to decide on the steel quality. AISI is short for the American Iron and Steel Institute. AISI 321 is one of those specific grades.

Stainless Steel 316 And 316L Graded By The AISI System

321 is a mix of chromium and nickel steel treated with temperatures ranging from 800 to 1500 degrees Fahrenheit. It is mainly used for equipment that is heavy welded because of its high resistance to substances.

321 steel has a titanium addition of up to five times its carbon content. It improves the elevated temperature properties of the alloy and is the catalyst for the steel’s improved intergranular corrosion resistance. Its resistance to organic and selected in-organic acids is also excellent. However, extended exposure to temperatures reaching around 900 to 1500 degrees may compromise its corrosion resistance.

Many things determine the physical properties of steel. Thermal conductivity, electrical conductivity, density, and melting range are all things that are measured per type of stainless steel.

Another way of determining the 321 stainless steel is by its chemical properties. It is the different levels and percentages of materials that are blended to create AISI 321. The notable thing to look out for is that 321 is a blend of nickel and chromium. Another thing is that this steel has high levels of titanium compared to other types.

Mechanical Properties are the measured strength in stainless steel. That includes tensile strength, elongation at break, Izod impact, modulus of elasticity, Charpy impact, etc. Each has a set number, percentage, or value for 321 stainless steel.

AISI 321 is under the Austenitic Stainless Steel Family. This family is usually considered to be weldable by the popular fusion and resistance processes. Its weldability can be compared to 304 stainless steel. One key difference is the prevention of lack of carbide precipitation due to the amounts of titanium in the steel.

When it comes to hot workability, often 321 is treated the same as 304 stainless steel. It turns out that 321 is slightly softer than 304 in terms of hot workability. The differences came from delta ferrite and from free nitrogen and carbon.

AISI 321 is one of the stainless steel that isn’t hardenable by heat treatment.

Try for free The application’s Guide to 301 Stainless Steel Strip

With the properties of 321 stainless steel, there are three areas that it is highly utilized. The first is Jet and aircraft components. Essentially, any part of an aircraft can be made with stainless steel, but 321 stainless steel provides more stability due to its intergranular corrosion resistance.

Another popular application is with oil refinery equipment. This is because the steel can withstand numerous substances, including organic and non-organic acids. Another use of 321 stainless steel is with stack liners because AISI 321 can withstand extreme temperatures.

AISI 321 can also be used in the food and beverage industry as well as the medical industry. This is because it can be easily disinfected and can withstand intense substances and acids. It can be washed with strong cleaners without compromising its quality, even with long-term use.

Get A complete guide to A Complete Guide to 316 Stainless Steel Plate sheets

304 stainless steel is considered to be the most popular kind of stainless steel. It is the industry standard that makes up for over half of the world’s stainless steel supply. 321 stainless steel is considered to be one of the stabilized grades. It is recommended for parts fabricated by welding which cannot be subsequently annealed. It is also the best steel to use for products that can withstand 427 to 816 degrees celsius.

There are distinct differences between 321 and 304 stainless steel. The most notable one is the addition of titanium and its carbon content. High carbon content means greater yield strength. 321 stainless steel’s excellent mechanical properties give it a slight advantage in high-temperature environments compared to 304. 321 also possesses improved ductility and higher resistance to stress fracture.

For heavy-duty parts or equipment that can withstand numerous hours of work each day, the 321 stainless steel is recommended. It is also ideal for environments with extreme temperatures or when dealing with extreme and volatile substances.

For everyday use in the house, clinic, or kitchen, 304 may be the better choice because of its abundance. 304 is also the most affordable and available in the stainless steel 300 series. It is used by many racing teams. It all depends on what the stainless steel is needed for.

Try for free information about the A Complete Guide to Stainless Steel Price

Stainless steel contains about ten percent of chromium. AISI 321 is general-purpose stainless steel under the austenitic family, so It is essentially non-magnetic.

Read more about A Complete Guide to Steel Coil Manufacturers

Due to its resistance to high temperatures, acids, and intergranular corrosion, 321 stainless steel may be optimal for food processing and storage. The best option, however, for food safety may be 316 stainless steel. This is because it has better chemical resistance through different applications.

Keep reading: A Complete Guide to Steel Coil Suppliers

321 stainless steel can resist rust well. Both 304 and 316 stainless steel can resist rust better than 321 stainless steel. Although all three types are rust-resistant, they differ in price, strength, and quality.

Always Provides You with the BEST Austenitic Stainless Steel Products

The titanium addition in AISI 321 stainless steel coil not only gives it superior resistance to intergranular corrosion, but also enhances its strength at high temperatures. The titanium atoms bond with the carbon atoms present in the alloy, preventing them from forming chromium carbide, which can lead to intergranular corrosion when the material is heated. Furthermore, 321 stainless steel also has good toughness at cryogenic temperatures, meaning it doesn’t become brittle even at very low temperatures. Its non-magnetic properties in the annealed state and its maximum use temperature are approximately 1500°F (816°C).

Exhaust systems are typically exposed to high-temperature conditions, making the selection of the right stainless steel crucial. While both 304 and 321 stainless steel have many similar properties, 321’s superior resistance to heat-induced stress and cracking, courtesy of its titanium addition, makes it a better choice for exhaust systems. That said, 304 stainless steel can also be a viable choice for exhaust systems in certain conditions, particularly those not involving prolonged high-temperature exposure.

AISI 321 stainless steel coil is manufactured by several reputed companies worldwide. Some of these include Outokumpu, a Finland-based company known for its high-quality stainless steel products; Acerinox, a Spanish manufacturer renowned for its comprehensive range of stainless steel products; POSCO, a leading South Korean steelmaker; ThyssenKrupp, a German multinational conglomerate with focus on industrial engineering and steel production; and Jindal Stainless Ltd, an Indian manufacturer known for its quality stainless steel products.

To purchase 321 stainless steel in bulk, or wholesale, it’s best to contact established steel distributors or wholesalers. They often have a large inventory of various types and forms of stainless steel, including AISI 321 stainless steel coil. When purchasing in bulk, always ensure that you’re working with a reputable wholesaler who can provide product certifications and demonstrate adherence to quality standards.

Benefits of buying wholesale include potential cost savings, especially for large projects, and greater availability of products. Plus, wholesalers often offer various value-added services, such as cutting to size, coil processing, and more, that can save you both time and resources.

It’s generally priced higher than 304 due to its superior performance in high-temperature environments, but typically lower than the 316 grade, which offers superior resistance to a wider range of corrosive environments.

Stainless steel continues to be one of the most utilized materials in construction. As technology continues to evolve, so will the different treatments and different types of stainless steel that will be created. The market will continue to grow, and the number of competitors will increase.

The key to finding the best quality stainless steel is to consider the factors involved. What the material will serve as, the price, size, and abundance. Once these are taken into consideration, individuals will have an easier time choosing the right kind of stainless steel for their needs.

Its unique properties make it a strong contender in various applications ranging from exhaust systems to high-temperature chemical processes. Plus, with the option to purchase in bulk from reputable manufacturers and wholesalers, securing the amount you need for your project is hassle-free. Considering all these factors, it’s clear why AISI 321 stainless steel is a popular choice among many professionals in the industry.

Visit Yaoyi now for more information about stainless steel products!

Read on: A Complete Guide to 201 Stainless Steel