Stainless steel is a durable and versatile steel alloy. It possesses the strength of steel along with an innate corrosion resistance making it in demand for various applications. In order to understand how it works, it is important to learn the stainless steel chemical composition.

Thus, this article by Yaoyi will be discussing its structure. After all, every property that this material has follows the root of its chemistry. We’ll define how different grades of stainless steel affect strength, resistance, and other dependent properties.

Myriad is a stainless steel company with over 25 years of excellent reputation. Moreover, Yaoyi specializes in manufacturing stainless steel products from different grades. So if you are looking for stainless steel products, visit Yaoyi and get your hands on some of the industry’s finest.

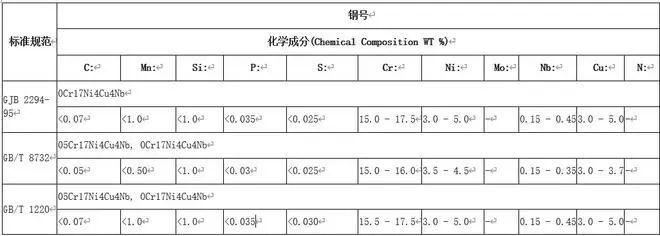

Stainless steel is an alloy primarily composed of iron, chromium, and few other elements. Chromium is the main distinguishing factor for stainless steel. A 10.50% minimum chromium content is required for steel to classify as “stainless”.

Furthermore, a stainless steel composition is not fixed and can vary to suit specific requirements. These variations in the steel’s composition result in different ‘grades’. So today, international regulators standardized these grades through a series of numerical identifications.

Keep reading: A Complete Guide to Steel Coil Suppliers

You can get the more cost-effective stainless steel material from Yaoyi.

Remember to contact us for free sample.

Each type has different properties and is suited to different applications.

In addition, it’s used in medical equipment, construction materials, automotive parts, and many industrial applications.

Properties of Stainless Steel Stainless steel is a desirable material for a variety of reasons. Here are the primary properties which set stainless steel apart from other steel or alloy types:

Corrosion and oxidation resistance is probably the most desired property of stainless steel. Stainless steel has excellent tolerances with corrosion and rusting, particularly the bane of most steels. Thus, it makes an excellent alternative for applications where regular steel won’t be practical like weather-exposed applications.

The mechanical properties of stainless steel stand on par even with high-strength carbon steel. Similarly, it has equal standing in terms of workability and formability. After all, stainless steel is also steel with few other elements like chromium and nickel infused. Nevertheless, these few tweaks in its elemental composition matter as it drastically changes how the material performs.

Stainless steel is also aesthetically versatile. The most common finish we see in the market is a polished finish, which itself is pleasing. However, unknown to most people, stainless steel can come on matte, tinted, textured, and other finishes. This variety adds more options that designers can utilize. Because of that, architects popularly use stainless steel for building shell designs, outdoor installations, interiors, and other numerous applications.

Among steel and metals used in construction, stainless steel has some of the highest fire resistance. It exhibits a critical temperature threshold of above 800 °C with non-toxic emission upon combustion.

Furthermore, stainless steel has an excellent capability for recycling. Therefore, It is considered a “green” material, and modern industries favor this capability as environmental awareness rises.

These are just the general features of stainless steel. As mentioned, there could be variations on these features depending on the compositional grade. Further details on how grades affect stainless steel performance are elaborated in the next section.

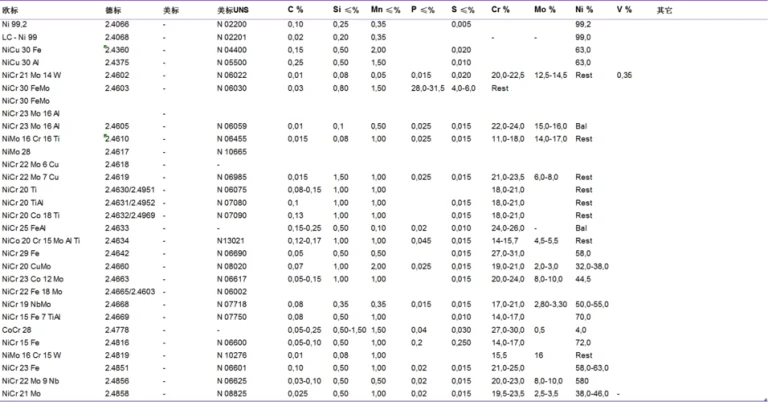

As stainless steel composition varies, so does the performance of the resulting grade. Below are the key features of the major grade series and their respective applications.

Austenitic 200 series is primarily distinguished by its chromium-manganese base, with a low nickel content of around 5%. They are an alternative for 300 series stainless steel design to answer the rare nickel supply in the earlier eras. Applications:

The Austenitic 300 series is also the most prevalent stainless steel series in the market. It is a chromium-nickel steel with 16% to 21% chromium content and 6% to 26% nickel. Additionally, it has a 0.015% to 0.10% carbon content and 0% to 7% molybdenum content. Nickel stabilizes the internal structure and adds corrosion resistance, while molybdenum further increases corrosion resistance thresholds. The most popular grades include 304 and 316. Applications:

Learn more about Why Do Customers Choose Yaoyi to Test The 304 Stainless Steel Yield Strength?

The 400 series is the most akin to regular or mild steel. This stainless steel series has a general composition of 0.02% to 0.06% carbon and chromium of 10.5% to 30%. It also has relative molybdenum amounts of 0% to 4%. Professionals commonly use them for internal applications due to lower resistance against corrosion. Applications:

Duplex series is a mixture of austenitic and ferritic compositions. This grade family has the strength of ferritic with improved resistance and flexibility of the austenite. Nickel is kept at low levels, an element typically subjected to unstable price changes. Moreover, compositional contents include 1% to 7% nickel with 21% to 26% chromium. It can also have carbon contents of 0.02% and 0% to 4% molybdenum. Applications:

Martensitic stainless steels exhibit excellent strength and hardness suitable for structural or precisional load applications. It has more carbon amounts, reinforcing strength, while a lower amount of nickel lowers its resistances. General distinct elemental content includes high carbon contents of around 0.1% and 10.5% to 17% chromium. Applications:

Read on 316L Stainless Steel Properties

Yes, stainless steel can rust as it is rust-resistant, not rust-proof. However, under typical conditions, rusting risk is highly negligible. The following are a few reasons that may cause your stainless steel to rust:

Different stainless steel grades showcase different performances on certain properties. For example, you might have used a ferritic grade for a marine application. Ferritic applications would surely deteriorate faster as their composition is more akin to regular steel. Meanwhile, using the right grade, like 316 for marine applications, would perform more efficiently as it is designed to.

Certain chemicals have adverse effects on stainless steel’s resistances. Thus, once the exposure exceeds the threshold, you can see signs of rusting or corrosion. For this matter, you can consult your local manufacturer on which chemicals to avoid.

The corrosion resistance of stainless steel is a homogenous property and is uniform throughout the material. However, particles of steel produced by abrasion can welcome rust formation on the surface level.

Deteriorating exposure plus time is among the most potent causes of rusting. Time, after all, wears out every material eventually, and the same holds for stainless steel.

Try for free The application’s Guide to 301 Stainless Steel Strip

There is no stainless steel grade which specifically is the best. The best grade is subjective of its application. So understanding your application is imperative to choose the best stainless steel grade for it.

As an example, grade 302 has decent properties overall. However, if you’re going to use it for medical prosthesis, there might be better grades for the job, like 316. It’s just a matter of a grade-to-application relationship. That’s the main reason why it’s important to have at least the basic information to guide on choosing between grade options.

Get A complete guide to A Complete Guide to 316 Stainless Steel Plate sheets

Stainless steel is made of metals and various other elements. But, it is not metal per se but an alloy.

Metal is the term for unique individual elements made up of fusible, ductile, and sometimes lustrous particles. Popular metals include aluminum, copper, and gold. To simply put it, metal has a specific designation on the periodic table of elements.

Meanwhile, steel is a combination or an alloy of iron and carbon, and other elements. It is a mixture of various elements, which can be metal or nonmetal. Stainless steel, carbon steel, and other alloys fall under this class. Therefore, categorically speaking, stainless steel is not a metal.

This confusion might have been caused by the use of the word ‘metal’ for anything with a metal’s characteristics. In most cases, it’s just a matter of context in discussion for understanding what is being referred to. Nevertheless, learning the distinction between steel and metal is educational.

Try for free information about the A Complete Guide to Stainless Steel Price

If you need a steel-durable and corrosion-resistive material, then it calls for the use of stainless steel. Additionally, it’s a steel substitute for weather-exposed use. To simplify, if you need steel but don’t want it to corrode or rust, use stainless steel.

Read more about A Complete Guide to Steel Coil Manufacturers

Steel is an alloy made primarily of iron and carbon. Typically, carbon makes up between 0.2% and 2.1% of the material’s weight. Other elements may be added to improve certain properties. For example, manganese helps with hardenability, and silicon can boost strength. Steel composition can vary significantly depending on the intended use and grade of the steel.

Steel is an alloy, or a combination of metals, predominantly made up of iron with small amounts of carbon. It’s known for its strength and durability, which make it a versatile material used in many industries, such as construction, transportation, and manufacturing.

The chemical structure of steel, like other metals and alloys, consists of a crystalline lattice. This lattice is formed by iron atoms, with carbon atoms occupying the interstitial spaces between them. The specific arrangement of these atoms and the presence of other elements can alter the steel’s properties.

Steel is not a compound, but an alloy. It is primarily composed of iron and carbon, but other elements such as chromium, nickel, or manganese may be added to impart specific properties to the alloy.

Steel is one of the most widely used materials in the world due to its strength and durability. It’s used in construction, for building structures, bridges, and tunnels; in transportation, for manufacturing cars, ships, and trains; in the energy sector, for oil and gas pipelines; and in many other industries, from cutlery to machinery.

Steel has several properties that make it a highly versatile material. It is strong, durable, and resistant to wear and tear. It’s also ductile, meaning it can be drawn out into a thin wire, and malleable, meaning it can be hammered or rolled into thin sheets. Furthermore, its properties can be altered through heat treatment and the addition of other elements.

Steel has been in use for thousands of years, but the process for making large quantities of high-quality steel was only developed in the mid-19th century. The Bessemer process, invented by Henry Bessemer in 1855, was the first inexpensive industrial process for mass-producing steel.

The price of stainless steel fluctuates based on a variety of factors, including market demand, raw material costs, and the specific type and grade of stainless steel. As of my last update in September 2021, I can’t provide a current price. For the most up-to-date information, I would recommend checking a reliable industry source or contacting a supplier directly.

Stainless steel composition is the basis of every property that the material exhibits. By understanding the compositional variations between grades, you can choose the right products.

For further concerns with stainless steel composition or related products, visit us at Yaoyi. With over 25 years of quality reputation, Yaoyi delivers only the best service and products. For anything stainless steel, Yaoyi is your reliable partner.

Keep reading: A Complete Guide to Steel Coil Suppliers