Thin stainless steel sheets to buy in china

The common steel grades of thin stainless steel sheets are sus 301, sus 304, sus 316, sus 316L, sus 430… Myriad is a factory specializing in the production of austenitic thin stainless steel sheets. You can buy 200 series and 300 series, various models and specifications of stainless steel in Myriad. The raw material of thin stainless steel sheets comes from Baosteel, the world’s largest steel company. High-quality control makes Myriad thin stainless steel sheets sold in 23 countries around the world. Mriad has been following the ISO9001 international management system certification. Since 1996, Myriad has been upholding the spirit of quality first, and control the production of stainless steel products you buy.

Ask Better Thin Stainless Steel Sheets Rate

1.Myriad factory covers an area of more than 230,000 square meters, and Yaoyi has a complete storage and production space. Myriad has a complete set of thin stainless steel sheets manufacturing and inspection equipment. Ensure that your thin stainless steel sheets orders are produced in a safe and friendly production environment. Myriad can provide a one-stop service for your thin stainless steel sheets. The storage area of more than 10,000 square meters can provide you with free storage in China. Omit your production scheduling.

2. As a thin stainless steel sheets manufacturer, Myriad has formulated a scientific and detailed operation manual. Ensure that the production personnel operate under international standards, and ensure that the thin stainless steel sheets you buy from raw materials (hot rolled coils) to finished products (thin stainless steel sheets) can meet your requirements.

3.When your need for thin stainless steel sheets is high elongation, high compressive strength。When your products are clamps, springs, some hardware, and subsea oil pipelines….. The thin stainless steel sheets produced by Myriad will be especially suitable for you. Myriad’s thin stainless steel sheets can achieve 10% higher elongation than similar products under the same hardness requirements. And the J3 hin stainless steel sheets and J4 hin stainless steel sheets developed by Yaoyi can replace 304 hin stainless steel sheets under certain conditions, which will give you an advantage in the market competition.

4. Myriad has a complete set of thin stainless steel sheets quality inspection equipment. Including chemical element testing, thickness width tolerance testing, hardness testing, tensile, yield, elongation testing, salt spray test testing, bending resistance testing, puncture resistance value testing, etc. After the thin stainless steel sheets you have purchased are produced, Yaoyi will conduct sampling inspections on the thin stainless steel sheets you purchased. Make sure that the thin stainless steel sheets you buy meet all your requirements. And will keep you samples for 1 year, you can re-test at any time.

5. Myriad‘s sales and after-sales service are online 24 hours a day. When you ask questions and needs, you can answer them . Help your decision-making.

Myriad Thin Stainless Steel Sheets to Double Your Profit

Ningbo Yaoyi New Material Co., Ltd. (formerly Ningbo Yaoyi Stainless Steel Co., Ltd.) was established in 1996 and covers an area of 50 acres. It is close to Ningbo Beilun Port and 10-15 minutes drive from Ningbo High-speed Railway Station, Ningbo Airport and Ningbo Automobile Passenger Transport Center Station. Our company mainly produces and sells 201 stainless steel belt, J1 stainless steel belt, J4 stainless steel belt, Y1 non-magnetic high-stretch stainless steel belt, Y6 non-magnetic special hard stainless steel belt, American standard 201 stainless steel belt, 202 stainless steel belt, 301 stainless steel belt, 301Ni7 stainless steel Belts, 304 stainless steel belts, 316 stainless steel belts, with raw materials available all year round, ready to provide you with the best quality service!

Our Thin Stainless Steel Sheets Products

All thin stainless steels strictly comply with the ISO 9001:2015 management system certification and are produced to the highest standards. There are video records throughout the production process.

What is the thinnest stainless steel?

At present, the thinnest stainless steel in the world is 0.02mm thick. Mass production is possible: thickness: 0.015mm, width: 600mm, which will be produced by TISCO in 2020.As a wide-width soft stainless steel foil, it is a high-end product in the field of stainless steel strip and is used in aerospace, defense, medical equipment, petrochemical, precision instruments, automobiles, electronics, home appliances, computers, and other fields. Before this, the thinnest stainless steel on the market was 0.02mm thick, which was produced by Taiyuan Iron and Steel in 2018.

Before TISCO produced 0.02mm stainless steel, the production technology of ultra-thin stainless steel was controlled by steel companies in Germany and Japan. After 2018, 0.03mm thick and 0.04mm thick stainless steel appeared on the market.

Cold rolling of this kind of ultra-thin metal foil requires high raw material purity and roll precision. During the processing, a slight vibration will cause rolling failure. A steel plate needs to be rolled several hundred times before it becomes a foil several times thinner than paper.

A Manufacturer of Stainless Steel Strips

What is thin stainless steel sheets called?

Stainless steel refer to the steel whose total alloying elements exceed 2.5% and has the ability to resist atmospheric corrosion. Stainless steel has excellent comprehensive properties, not only good corrosion resistance, but also high strength, high temperature and high pressure resistance, radiation resistance, low temperature resistance, weld ability, ease of processing, high surface finish and good surface stability, etc. Excellent performance, plays an irreplaceable role in many fields. In some industries, such as printing industry and decoration industry, it is more widely used. Stainless steel refer to the steel whose total alloying elements exceed 2.5% and has the ability to resist atmospheric corrosion. Stainless steel has excellent comprehensive properties, not only good corrosion resistance, but also high strength, high temperature and high pressure resistance, radiation resistance, low temperature resistance, weld ability, ease of processing, high surface finish and good surface stability, etc. Excellent performance, plays an irreplaceable role in many fields. In some industries, such as printing industry and decoration industry, it is more widely used.

Most steel companies do not produce thin stainless steel sheets. Because thin stainless steel sheets are bulky, costly, difficult to pickle, and inconvenient to transport. Common thin stainless steel sheets are obtained from stainless steel coils after the flattening process.

Stainless steel plates are generally classified according to thickness or production method. According to the production method, it is classified into a cold-rolled steel plate and hot rolled steel plate.

Classified by thickness:

Stainless steel foil: thickness below 0.05mm

Very thin belt: the thickness is 0.05-0.2mm;

Thin plate: the thickness of 0.2-3mm;

Middle plate: the thickness of 3-20mm;

Thick plate: the thickness is 20-60mm;

Extra-thick plate: The thickness is above 60mm.

Common stainless steel plates are cold-rolled stainless steel plates as shown in the figure below, which are thin and have bright surfaces, referred to as 2B plates; hot-rolled stainless steel plates, which are thicker, have pickling white surfaces, referred to as NO.1 plates.

Also to distinguishing stainless steel plates by surface conditions, they are also classified according to chemical composition, organizational structure, stainless steel use, and stainless steel functions.

According to chemical composition elements, thin stainless steel sheets are divided into chromium stainless steel plates, chromium-nickel stainless steel plates, chromium-nickel molybdenum stainless steel plates, low carbon stainless steel plates, high molybdenum stainless steel plates, and ultra-high purity high chromium ferritic stainless steel plates.

According to the organization structure, thin stainless steel sheets can be divided into austenitic stainless steel sheets, ferritic stainless steel sheets, martensitic stainless steel sheets (including precipitation hardened stainless steel sheets), and duplex stainless steel sheets.

According to chemical composition, thin stainless steel sheets are divided into chromium stainless steel plate, chromium-nickel stainless steel plate, chromium-nickel molybdenum stainless steel plate, low carbon stainless steel plate, high molybdenum stainless steel plate, and ultra-high purity high chromium ferritic stainless steel plate.

According to the application, thin stainless steel sheets can be divided into nitrate-resistant stainless steel sheets, sulfuric acid-resistant stainless steel sheets, stress corrosion-resistant stainless steel sheets, and high-strength stainless steel sheets.

According to the functional characteristics, thin stainless steel sheets can be divided into low-temperature stainless steel sheets, non-magnetic stainless steel sheets, free-cutting stainless steel sheets, and micro stainless steel sheets.

A Complete Guide to 304 Stainless Steel Strapping

How much is a thin stainless steel sheets?

Stainless steel plates have different surfaces and different thicknesses, surface 2b, ba, 8k, NO.1, NO.4, and different prices are required.

When you buy stainless steel plates, you need to tell the seller the model, surface, width, thickness, and hardness of the stainless steel plate you need. If you are not sure what surface you want, you can tell the seller your purpose, so that the seller can recommend a suitable one for you Your stainless steel plate.

Also, the price factors that affect the stainless steel plate include the delivery date. If you need to get it immediately, the price will usually be high. If you can accept the 15-day delivery date, the price of the stainless steel plate will below.

Common stainless steel plates are: 304 stainless steel, 201 stainless steel, 301 stainless steel, 430 stainless steel, 409 stainless steel, 321 stainless steel, and 316 stainless steel.

Common stainless steel plate specifications (length * width): 1219mm* 2438mm, 1000mm*2000mm,

1219mm*3500mm, 1500mm*6000mm, 1219mm*4000mm, 1500mm*3000mm, 1219mm*4000mm

Common thicknesses are: 0.3mm, 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm.

Stainless Steel Rolls: Everything You Should Know – YAOYI Stainless Steel

What is the thickness of 304 thin stainless steel sheets?

304 stainless steel is divided according to the form: 304 stainless steel plate, 304 stainless steel coil, 304 stainless steel tube. When the form of 304 stainless steel is stainless steel plate or stainless steel coil, the thickness range: 0.02~60mm. Stainless steel foil: thickness below 0.05mm thin stainless steel sheet: the thickness is 0.05-0.2mm; Thin plate: the thickness of 0.2-3mm; Middle plate: thickness 3-20mm; Thick plate: the thickness is 20-60mm;

304 stainless steel is the most widely used chromium-nickel stainless steel. As a widely used steel, it has good corrosion resistance, heat resistance, low-temperature strength, and mechanical properties; it has good hot workability such as stamping and bending without heat treatment. Hardening phenomenon (use temperature -196℃~800℃). 304 stainless steel is widely used in the manufacture of deep-drawn forming parts and acid pipelines, containers, structural parts, various instrument bodies, etc., as well as non-magnetic, low-temperature equipment and parts. The standard stainless steel grade in Japan is: SUS304, and the standard stainless steel grade in China is: 06Cr19Ni10. The standard stainless steel grade in Europe is: EN10028-7: 2007.

The chemical composition of 304 stainless steel:

|

C |

Si |

Mn |

Cr |

Ni |

P |

S |

|

0.07 |

1.0 |

2.0 |

17.0~19.0 |

8.0~11.0 |

0.035 |

0.03 |

It is resistant to corrosion in the atmosphere. If it is an industrial atmosphere or heavily polluted area, it needs to be cleaned in time to avoid corrosion. It is suitable for food processing, storage, and transportation. Has good processing properties and weldability.

The stainless steel foil provided in China with high quality and best price.

How can I tell if my thin stainless steel is 304?

Detecting the material of stainless steel is what we often call the grading appraisal. The grade appraisal is mainly to analyze its chemical composition, and then classify the metal grades according to relevant testing standards. Therefore, the scientific detection method is naturally based on the relevant regulations of the national standard. Using precision instruments such as inductively coupled plasma atomic emission spectroscopy (ICP-OES), X-ray fluorescence spectrometer (XRF), carbon-sulfur analyzer, scanning electron microscope, and energy spectrum analyzer (SEM+EDS), the analysis of all elements and total of metal materials The components are analyzed qualitatively, semi-quantitatively, and quantitatively. According to the American standard, ISO international standard, European standard, German standard, Japanese standard, etc., the metal grade identification and element analysis are carried out.

Magnets cannot be detected scientifically. There are many types of stainless steel, some are magnetic, some are weakly magnetic or non-magnetic. The most scientific method is to use a spectrum analyzer to test the content of chemical elements, which can be clear at a glance! 304 contains 8-9% nickel and 18-19% chromium. If this value is not reached, it is not a 304 material!

It is a powerful tool and “weapon”. Of course, if you have economic conditions, you can buy a spectrometer. Of course, the price is quite expensive. There is another simple method. Each stainless steel sales market will have a laboratory. The purchaser can cut a small piece and take it for testing. The price is cheap and accurate.

2. Use magnetism to judge whether 304 stainless steel is true or not. 304 stainless steel is magnetic. So, 304 stainless steel that uses magnets to attract magnets will show weak magnetism, so to distinguish whether 304 stainless steel is true or false.

3. Use a professional spectrum analyzer or a handheld X-ray fluorescence spectrometer to identify the composition of stainless steel.

The chemical composition of 304 stainless steel:

|

C |

Si |

Mn |

Cr |

Ni |

P |

S |

|

0.07 |

1.0 |

2.0 |

17.0~19.0 |

8.0~11.0 |

0.035 |

0.03 |

If the composition of stainless steel is within the range of the above figure, then it is 304 stainless steel.

Stainless steel coil with high-quality and low-MOQ is provided in China.

What is the difference between 304 and 308 stainless steel?

The chemical composition of 308 stainless steel:

|

C |

Si |

Mn |

Cr |

Ni |

P |

S |

|

0.08 |

0.75 |

2.0 |

19.0~21.0 |

10.0~12.0 |

0.045 |

0.03 |

National standard number: 06Cr20Ni11.

308 (S30800) belongs to the American standard austenitic stainless steel, the implementation standard: ASTM A276/A276M-17.

308 (S30800) stainless steel has good resistance to intergranular corrosion due to its low carbon content. It has the characteristics of low work hardening tendency and low magnetism, suitable for cold working and low magnetism requirements.

The chemical composition of 304 stainless steel:

|

C |

Si |

Mn |

Cr |

Ni |

P |

S |

|

0.07 |

1.0 |

2.0 |

17.0~19.0 |

8.0~11.0 |

0.035 |

0.03 |

Both 308 stainless steel and 304 stainless steel are austenitic stainless steel. The difference is that the Ni content of 308 stainless steel is 10.0~12.0, while that of 304 stainless steel is 8.0~11.0.

Ni element is one of the main elements forming austenite.

The weldability of 308 stainless steel is better than that of 304 stainless steel.

After 308 stainless steel is used to weld 304 stainless steel, it is non-magnetic, which can reduce micro segregation and improve stress resistance and corrosion resistance. But, due to the market scarcity of 308 stainless steel, the price of 308 stainless steel is higher than that of 304 stainless steel.

Stainless Steel Chemical Composition

How can I tell if my stainless steel is 304 or 316?

In the smelting process of stainless steel, different steel grades are formed due to the addition of different alloying elements such as nickel and manganese. The characteristics of each steel grade are different, and the chemical composition and physical characteristics are also different. Therefore, to distinguish each steel grade, countries in the world have made different standards and names for them. Take 304 stainless steel as an example. Because the Japanese JIS standard (SUS304) is the reference American standard, and the Chinese GB standard (06Cr19Ni10), the most commonly used is the American ASTM standard. It is directly called 304 stainless steel.

Performance introduction and scope of use

304 stainless steel is a kind of stainless steel with a very wide range of use. 304 stainless steel has very good corrosion resistance and heat resistance. At low temperatures, its mechanical properties are still very good. 304 stainless steel has good hot workability. 304 stainless steel is non-magnetic and has good heat resistance. Working temperature: temperature -196℃~800℃).

Due to the addition of molybdenum, 316 stainless steel has better corrosion resistance, atmospheric corrosion resistance, and high-temperature strength than other steel types. It has better grain boundary corrosion resistance than 304 stainless steel. It can be used under harsh conditions and has excellent work hardening properties ( Non-magnetic). It is widely used in coastal areas, food products, and medical industries.

How to distinguish between 304 stainless steel and 316 stainless steel?

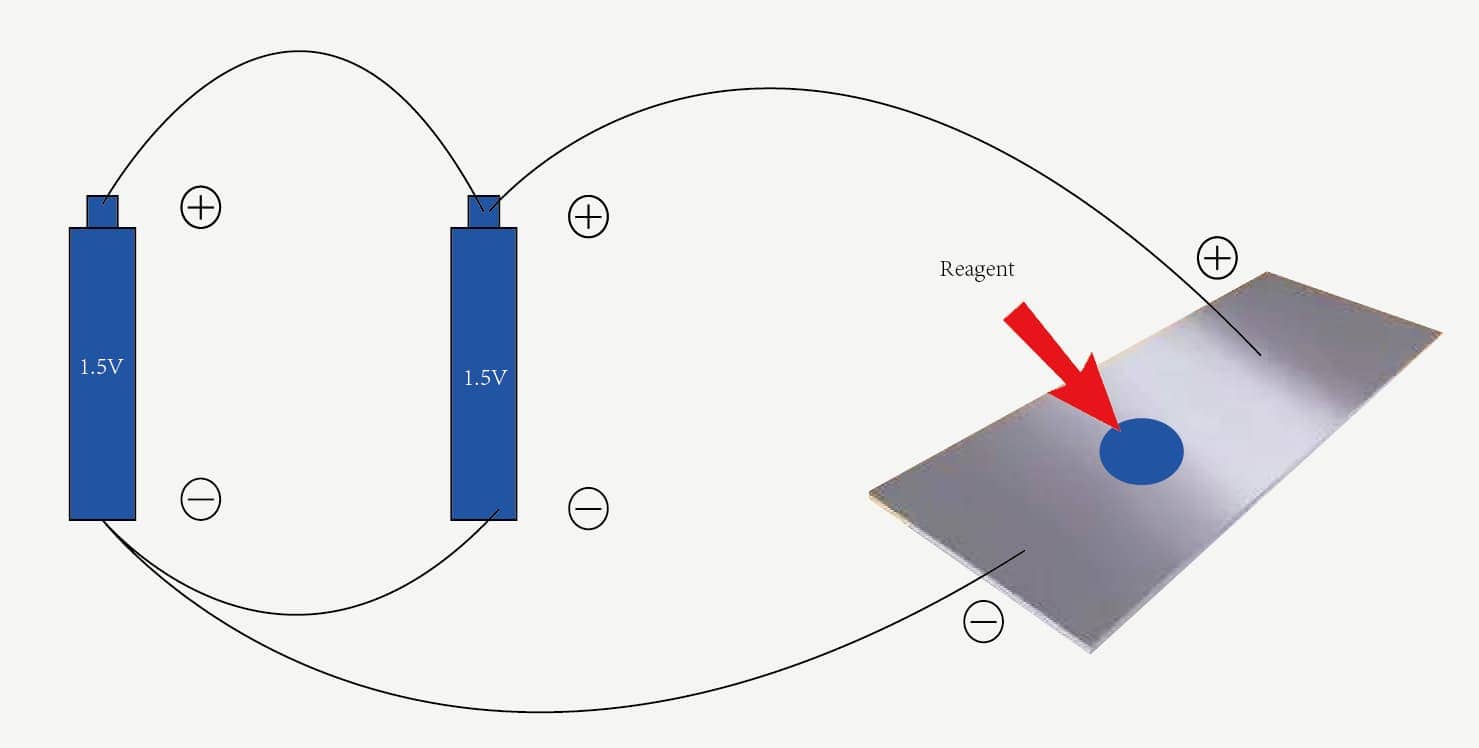

1. Reagent identification

Reagent formula: NH4SCN—15g, 37%HCL—5ml, SnCL2–10g, C9NH8OH–0.5g, distilled water–100ml.

Put a drop of the reagent on the stainless steel material, connect the positive electrode of the battery to the stainless steel, and the negative electrode contacts the identification solution, and the current is passed through. The discriminating fluid will turn black or pink, and the one that turns pink or white immediately becomes 304 stainless steel. Will not fade or fade to 316 stainless steel.

2. Use a professional spectrum analyzer or a handheld X-ray fluorescence spectrometer to identify the composition of stainless steel.

Stainless Steel Cable Ties – YAOYI Stainless Steel

Is 304 stainless steel rust proof?

304 stainless steel is the most widely used chromium-nickel stainless steel.

“304 stainless steel” is a grade of stainless steel produced by the American ASTM standard. This standard states: the steel must contain more than 18% chromium and more than 8% nickel. If only one of the chromium-nickel content meets the standard, it cannot It is called “304 stainless steel.” If the chromium-nickel content reaches this standard, then it can be called “304 stainless steel.” With the guarantee of the content of these two chemical elements, then it has corrosion resistance and also It is not easy to “rust”, so it can be safely used in food-grade products.

Since it is said that it is not easy to rust, then it is still possible to rust, but this possibility is very small, then under what circumstances will it rust?

A situation related to our daily life is that it is prone to rust in a chloride ion environment. What kind of environment is chloride ion environment? Generally refers to the environment of salt, sweat, sea water and sea breeze. So in Jiaxing, in our daily life scene, the 304 stainless steel material may rust the sink, how to avoid rust? It is to keep dry after cleaning. But for cabinet accessories such as pull baskets that are relatively in a dry environment, it is unlikely to rust.

But, some owners often say that the pull basket in their home has rusted after being used for a long time. The more likely reason is that it is not made of authentic 304 stainless steel.

Also to cabinet fittings, “304 stainless steel” can be used as food-grade materials, such as: 304 stainless steel pots, 304 stainless steel tableware and so on used in our lives.

It should be noted that its price is more expensive than ordinary materials, but it is a product that our ordinary people can afford. The only thing you need to know is that if a “304 stainless steel” pot on the market sells for about 100 yuan, and you see that the same product in a certain store only sells for half the price, then you have to be more vigilant, it is probably a merchant Instead of finding a “good” product with shoddy eyes.

After talking about “304 stainless steel”, let’s talk about its “upgrade” products. I call it an “upgraded” product because of its better corrosion resistance. With its existence, there is no need to worry about the risk of rust in extreme environments, such as scalpels, marine accessories, etc.

The name of the “upgraded” product is called “316 stainless steel”. Remember the nickel content in “304 stainless steel”? The “upgrade” of “316 stainless steel” is mainly based on keeping the chromium content at 18% and increasing the nickel content from at least 8% to at least 10%. Now many tableware also use this material, and its identification in the tableware is 18- 10. The identification of “304 stainless steel” in tableware is 18-8.

Also to the different signs, the prices of the two are quite different. In general, “316 stainless steel” is more than twice as expensive as “304 stainless steel”.

Finally, to sum up, “304 stainless steel” has good corrosion resistance, it is not easy to rust, and it is a good helper for home life.

Stainless Steel Belt: Characteristics, Advantages, and Applications

What size does stainless steel sheet come in?

stainless steel sheet is divided into: cold-rolled stainless steel sheet, hot-rolled stainless steel sheet and medium thick plate

1. Thickness of cold-rolled stainless steel sheet: 0.3-6.0mm Cold-rolled stainless steel sheet size specification: 1000*2000 1220*2440 1220*3050 1220*4000 1500*3000 1500*6000 width fixed length can be flattened according to requirements

2. Thickness of hot-rolled stainless steel sheet: 3.0-16.0mm Hot-rolled stainless steel sheet size: 1500*6000 1800*6000 2000*6000 width fixed length can be flattened according to requirements

3.Thickness of medium and heavy plate: 18-100mm Size of medium and heavy plate: 1500*6000 1800*6000 2000*6000 Both length and width can be cut on demand

Stainless Steel AISI 316Ti (S31635) By The AISI System

What gauge sheet metal is used on cars?

Features of austenitic Thin stainless steel sheets:

1. The crystal structure is face-centered cubic at high and low temperatures, and the matrix structure is austenite.

2. Excellent corrosion resistance, mechanical properties cannot be changed by heat treatment, and can only be strengthened by cold deformation.

3. Non-magnetic, good low-temperature performance, formability, and excellent weldability. ,

4. High cost.

5. Representative grades and applications: 304 Thin stainless steel sheets, 304L Thin stainless steel sheets, 321 Thin stainless steel sheets, 316 Thin stainless steel sheets, 316L Thin stainless steel sheets.

Hot-rolled plate: flanges, gaskets, brackets, frames, and parts with high requirements for resistance to intergranular corrosion.

Cold-rolled sheet: automotive fuel tanks, exhaust systems, gaskets, gaskets, gaskets, seals, wipers, and other components that require corrosion resistance.

Features of martensitic Thin stainless steel sheets:

1. It is austenite at high temperature, and the crystal structure is face-centered cubic; at room temperature and low temperature, it is martensite, and the crystal structure is body-centered cubic.

2. General corrosion resistance, but with high strength, suitable for high-strength structural parts, strengthened by cold deformation.

3. It is magnetic at room temperature.

4. Representative grades and applications: 410 Thin stainless steel sheets, 420 Thin stainless steel sheets

Hot-rolled plate: commonly used in automobile brake pads and frame parts with corrosion resistance requirements and combined frames.

Cold-rolled plate: commonly used for support parts with corrosion resistance and high strength requirements.

Features of ferritic stainless steel plate:

1. The crystal structure at high and low temperatures is body-centered cubic, and the matrix structure is ferrite.

2. The comprehensive corrosion resistance is not as good as the austenitic stainless steel, but the stress corrosion cracking resistance is worse than the austenitic stainless steel.

3. With strong magnetism at room temperature, it cannot be hardened by heat treatment, and has the excellent cold working performance.

4. The cost is much lower than austenitic stainless steel.

5. Representative grades and applications: 409L Thin stainless steel sheets, 430 Thin stainless steel sheets, 436 Thin stainless steel sheets, 436L Thin stainless steel sheets, 441 Thin stainless steel sheets.

Hot rolled plate: exhaust system bracket and other parts. Cold-rolled plate: automobile exhaust system, gaskets, gaskets, brackets and plate heat exchangers, and other parts.

J4 stainless steel Food Grade : the best you can find & purchase.

What can i use to cut thin stainless steel sheets?

In the shearing and cutting of thin stainless steel sheets, the most widely used method is to use a shearing machine, which is suitable for ordinary carbon steel and thin stainless steel sheets. The knife for cutting thin stainless steel sheets is made of high-speed bai tool steel. In order to obtain a smooth edge, the cutting surface of the tool must be sharp and free of burrs.

thin stainless steel sheets, especially austenitic stainless steels, have higher ductility, so you must reduce the gap between the cutters when cutting, and ensure that the cutting is clear. Do not plastically deform the stainless steel or pull down to cover the cutter. Before the fracture occurs, the cutter should cut to half of the plate thickness, and the margin at this time is more suitable. Excessive tool allowance will cause damage to the tool, and there will be very large burrs on the edge of the cut steel plate.

J3 Stainless Steel : A Complete Guide For Importers

What grade of stainless steel will not rust?

304 thin stainless steel sheets, 316 thin stainless steel sheets, and 316L thin stainless steel sheets are of relatively better quality.

The reason is that these stainless steels contain a high content of chromium and nickel. They are all austenitic thin stainless steel sheets. Although thin stainless steel sheets is very resistant to corrosion, it does not mean that it will not rust. thin stainless steel sheets is more likely to be corroded by “chlorine substances.”

J2 Stainless Steel: A Complete & Thorough Guide

What prevents thin stainless steel sheets from rusting?

The first type: is to directly use anti-rust oil to prevent rust, that is, the so-called oil film anti-rust, and it is called physical anti-rust. The second: is the so-called chemical anti-rust method, which is the passivation anti-rust method of stainless steel that is often used by customers now. The anti-rust agent is a kind of metal anti-rust, and it is called a chemical passivation anti-rust method. while the passivation of stainless steel is that only the stainless steel passivation liquid contacts the surface of the workpiece to produce a chemical reaction, which converts the stainless steel chromium-poor layer into a chromium-rich layer to make The workpiece achieves the anti-rust effect of high salt spray, which is dozens of times stronger than traditional anti-rust oil, and the surface is clean and refreshing.

We don’t recommend you to use traditional anti-rust oil, because it has a short anti-rust time, low salt spray resistance, and has an oil film on the surface that is not clean and refreshing. Compared with stainless steel passivation fluid, it is much worse, so we recommend that you all adopt stainless steel. Passivation chemical antirust method, unless the oil film antirust is selected under specific conditions. The stainless steel passivation solution only needs to be immersed in a simple way, no complicated equipment, and no need to heat the liquid.

“Stainless steel passivation liquid” can effectively protect the metal substrate, extend the anti-rust or oxidation resistance of stainless steel, increase the anti-rust ability by at least 6 times, increase the salt spray resistance test time, and extend the service life of the workpiece.

There is also a special metal polishing spray. After removing the rust, spray a little and it is almost like new. But it’s not very cost-effective for you to buy two potions a little bit. For rust removal, you can try mixing vinegar and baking soda. It should have some effect.

Is 301 Stainless Steel Magnetic?

How can I fix rust on thin stainless steel sheets?

1. Spray a small amount of gasoline on a sponge or a clean cloth to wipe the rust on the stainless steel. Of course, you must be prepared to prevent gasoline from burning.

2. If it is relatively small stainless steel items such as tableware, you can soak in vinegar or spray vinegar on the rusty area of stainless steel products, and wipe the rust after 5 minutes.

3. Mix the baking soda and lemon juice into a paste, then wipe the rusty area with a sponge or a clean cloth, it is best to stop for a few minutes, the rust removal will be more smooth.

4. Mix about one tablespoon of baking soda with two cups of water. The amount of baking soda can be increased according to the degree of rust. Then wipe the rusty spots on the stainless steel with a sponge or a clean patch

5. If rust is on a vertical object, place the paper tray or paper under the rusty area. Then, dip your fingers in the baking soda and gently brush it into the wet and rusty area. Baking soda should stick to the rusty place. After the baking soda is attached, wait 30-60 minutes before wiping.

6. If the rust of stainless steel products is very serious, you can spray oxalic acid cleaner on the rust, and then wait for one minute to wipe with water.

How To Find The Right Stainless Steel Supplier