People often asked about the density of stainless steel, the density of stainless steel 304 and the density of stainless steel 316. When it comes to us, we will try to give you the best answer.

Yaoyi has been specializing in the research and development, production and sales of high-precision stainless steel strips since 1996. As a manufacture, Yaoyi has 25 years of experience in the production of stainless-steel products. At the same time, Yaoyi owns 50 acres of land, which is used to build factories and complete production.

Try for free information about the A Complete Guide to Stainless Steel Price

We have a lot of related testing instruments that can test the physical properties and chemical composition of stainless steel. The application of stainless steel slitting machine, stainless steel slitting machine, stainless steel flat cutting machine and other equipment to ensure that customers can get the products they want. If you are going to purchase some common products, you can find them in Yaoyi with a lower price. What is more, you can also find the special ones with high quality through our customization.

A professional team serves Yaoyi’s production. At present, Yaoyi mainly produces various stainless steels such as 201, 301, 304, 304L, 310S, 316L, 430, etc.. You can get the products of a thickness range 0.05mm~2.0mm. Soft, hard, and super-hard precision cold-rolled stainless steel strips, steel plates and coils are produced by our team. Moreover, in the following article, we will introduce the density of stainless steel.

Stainless Steel Chemical Composition – YAOYI Stainless Steel

Cooperate with Yaoyi, you don’t have to worry about the product and follow-up issues. Our precision cold rolling mill, vertical bright annealing line, horizontal annealing line, leveling and tempering machine, tension leveling machine and other sets of precision stainless steel professional production equipment can make the products perfect. With the certification of ISO9001. Yaoyi is producing products that comply with ASTM, AISI, JIS and other international standards.

With the help of high-quality raw materials and reliable supply chain, the advanced equipments in Yaoyi can be fully used. Trying to cooperate with Yaoyi means quality craftsmanship and technology, perfect business management. You can save lots of time and money by our customized products and professional consulting services.

Get A complete guide to A Complete Guide to 316 Stainless Steel Plate sheets

Density is one of the many properties every matter possesses. In steel manufacturing, the density of stainless steel is a factor to consider in designing materials or components. You can use it to define how elements will make up an alloy. You can dictate the following depending on the alloy’s specific elements:

Furthermore, density has specific relations to other properties. This makes it significant to use the material. Stainless steel has features like corrosion resistance which its elemental density can manipulate. At the same time, changes in the material composition can influence the density. It is essential to understand these relationships to optimize their usage.

This article will discuss how the density of stainless steel affects it as a material. Read on to know more about stainless steels’ density and its relation to specific gravity.

Try for free The application’s Guide to 301 Stainless Steel Strip

Stainless steel is an alloy of Carbon (C) and Iron (Fe) and other elements related to other steel. However, Chromium’s (Cr) presence makes it different, accounting for its corrosion resistance property. In general, stainless steel consists of 10.50% of Chromium. But, some variations exist, creating specific grades.

These stainless steel grades will have variations in their density, even without excessive standard ratio differences. Manufacturers make grade variations to maximize the use of composites of steel for specific applications. Mainly, you may check specifications issued by your manufacturer for a complete grasp of its properties.

Read on 316L Stainless Steel Properties

Scientifically, density is defined as mass per unit volume. In layman’s terms, the amount of an object’s matter with space it has or occupies. It represents the formula of Density (ρ) = Mass(m)/Volume(V). Density is commonly defined as the units of grams per cubic centimeter or kilograms per liter.

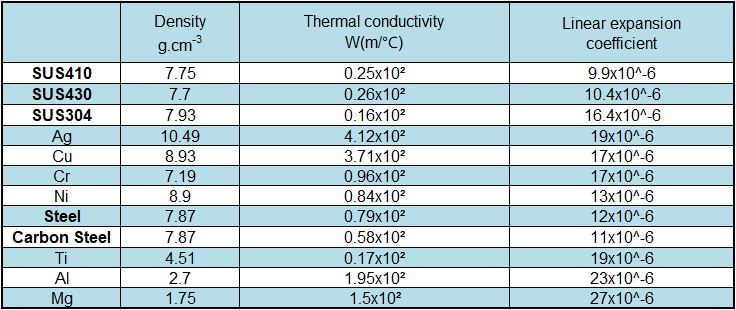

Stainless steel has a density range of 7.9 – 8.2 g/cm3 under typical room temperature. The specific density for respective grades will differ because of the variations between their composition elements’ percentages. For example, the density of stainless steel 304 is different from the density of stainless steel 316. Manufacturers utilize variations in elements to tone down or emphasize specific features of the stainless steel.

Learn more about Why Do Customers Choose Yaoyi to Test The 304 Stainless Steel Yield Strength?

In scientific terms, density is directly proportional to pressure and indirectly proportional to temperature. Meaning, density increases as pressure does in a fixed temperature. Meanwhile, density decreases as temperature increases in a fixed pressure.

This relationship affects how stainless steel or steel, in general, will react to certain conditions. For example, choosing an aircraft’s materials will require specific densities to maintain proper weight and balance. The same also accounts for the creep factor for aircraft. This creep factor is the natural tendency of a material to move or deform due to mechanical stress or strain.

Of course, stainless steel or any steel needs to meet these requirements. Otherwise, it will be risky and costly to remedy the material failure.

Stainless Steel Belt: Characteristics, Advantages, and Applications

Among the other stainless steel grades, 304 and 316 are the most used. However, being in the same category and composition as a stainless still does not mean their densities are the same. To enumerate, grade 304 has a density of 7.93 g/cm3, while 316 has 7.98 g/cm3. The same density accounts for their respective sub-variations like grade 304L and 316L.

This difference in density between the two grades’ densities results from elemental variations in its alloy. In grades 304 and 316, grade 316 has a bit more nickel (Ni) and molybdenum (Mo). Nickel and molybdenum are dense metals, which results in 316 being denser.

In the same context, nickel and molybdenum account for better chemical and corrosion resistance. Thus, stainless steel grade 316 has better corrosion resistance than 304. This feature makes it an ideal material for the chemically exposed environment like marine applications and medical devices. However, these elements also come at extra cost making 316 more expensive than 304.

On the other hand, grade 304 has a better melting point, roughly 50-100 degrees Fahrenheit, higher than 316. As a relatively cheaper material, you can use it more on general stainless steel applications.

To enumerate, these applications include:

Stainless Steel AISI 316Ti (S31635) By The AISI System

So which is better among these two grades? Well, the answer depends upon how you will use them. If you need standard stainless steel exposed to only mildly harsh conditions, then 304 should be your pick. However, if you need to use stainless steel on harsh chemicals, 316 is your best choice.

These stainless steel grades have their respective perks, which you can consider to avoid unnecessary expenses. Manufacturers typically issue these specific properties every grade has as a reference for their clients. Be sure to check them out and make sure it fits your applications.

What is J4 Stainless Steel? (And What Is It Used For)

Specific gravity is the relation of a material’s density with water’s density. Thus, this also means that materials exhibiting higher specific gravity values are heavier since density is directly proportional to mass. Every material has its specific gravity, which gives it a particular intuitive character, weight, and touch.

This property is more relatable to architectural applications of stainless steel. Specific gravity regards how certain material “feels” with its application. As an example, polymers or plastics have very low values for specific gravity. Therefore, it is lightweight and can feel lesser value than other materials with high specific gravity values. Thus, this where you get the feeling that it is “cheap’ or fragile.

You can always treat plastics to look like other materials. However, once you tap the material, the sound it makes corresponding to specific gravity will reveal its original make. It greatly contrasts with most steel materials by their density and corresponding specific gravity.

J3 Stainless Steel : A Complete Guide For Importers

Stainless steel is a material widely used in contemporary architecture. It is a famous material to use for weathering exposed areas because of its corrosion resistive property. From handrails to claddings, stainless steel is an all-around player. One famous and bold example is Frank Gehry’s Stainless Steel Cladding on Disney Concert Hall or his general works.

Correspondingly, stainless steel having a higher density makes it appear more valuable. Steels have high specific gravity because of their dense crystalline structure. You can feel this property by touching it, and you can hear the sound it makes as you tap it. Thus, this is where you get the “feel” of value from the resonating sound coming from its dense internal makeup.

The density of stainless steel is to be considered in structures, especially if it covers many areas. For instance, the relation of temperature and pressure on its density is highly relevant if the materials are exposed outdoors. Therefore, you will need certain grades with a specific density of stainless steel to fit a function.

J2 Stainless Steel: A Complete & Thorough Guide

For most stainless steel alloys, including 304 stainless steel, the density is approximately 8.0 g/cm3. This means that a cubic centimeter of 304 stainless steel weighs 8 grams. Density is a critical property in many applications because it directly influences the weight of the finished product.

SS 304, or AISI 304, is one of the most widely used stainless steel grades, appreciated for its versatility. The mechanical properties of a material define how it responds to applied forces, such as tension, compression, and shear:

The density of stainless steel 316 is also approximately 8.0 g/cm3, similar to 304. The slight differences in density between various types of stainless steel are mainly due to different alloying elements. 316 stainless steel, for instance, contains molybdenum, which enhances its resistance to chloride corrosion.

SS 304’s specifications include its chemical, mechanical, and physical properties:

Converting the metric density to Imperial units, the density of 304 stainless steel is approximately 0.289 lb/in3. This conversion is useful for industries that operate primarily with Imperial unit systems.

The specific density of a material is just another term for its density. So, the specific density of 304 stainless steel is about 8.0 g/cm3 or 0.289 lb/in3. This property is essential in a variety of engineering calculations, including weight and volume estimates, structural analysis, and heat transfer calculations.

The density of stainless steel is a factor with many other correlations. This knowledge will be handy to understand how to pick and apply certain stainless steel grades. Manufacturers or metallurgists should enumerate these properties to assure their specification compliance. You may have no idea about the density of stainless steel 304 and the density of stainless steel 316, however, you should always look for a trustworthy steel manufacturer if you want to get the best value for money.

Remember that there is more than meets the eye for stainless steel or materials in general. For this reason, it is essential to familiarize ourselves with its specific properties to optimize its use. It is more vital if you plan to be involved in steel manufacturing, design, or engineering.

At Yaoyi, you can get top-quality stainless steels you can get in the market.

The density of stainless steel is a critical property that differentiates it from mild steel. This comparison is fundamental for engineers, architects, and materials scientists.

| Material | Density (kg/m3) |

|---|---|

| Stainless Steel | 8000 |

| Mild Steel (density of mild steel in kg/m3) | 7850 |

Different compositions of elements cause variations in the density of steel. For stainless steel, the inclusion of chromium and nickel leads to a slightly higher density compared to mild steel.

The higher density of stainless steel gives it strength and corrosion resistance, whereas mild steel has a slightly lower density, which makes it more malleable.

Both stainless steel and mild steel are produced using similar processes. However, the specific alloys included can alter the density of the material.

Understanding the density of steel helps in choosing the right material for various applications such as construction, automotive, and aerospace.

Accurate measurements of density can be achieved through methods like the water displacement technique and using specific laboratory instruments.

Different countries follow specific standards for measuring and defining density, following international norms and regulations.

Stainless steel's density makes it a preferred choice for applications requiring longevity and resistance to environmental factors.

Understanding the density of stainless steel and mild steel is vital for various industrial applications. It helps in material selection, quality control, and contributes to sustainable development.

The density of steel 304 is a significant factor that sets it apart from other stainless steel types. The unique composition of steel 304 leads to its specific density.

Steel 304 consists of chromium, nickel, and a balanced combination of other elements, making its density approximately 8000 kg/m3 (density of stainless steel 304).

The manufacturing of steel 304 involves specific alloys and a well-controlled process to maintain the desired density and properties.

The density of steel 304 makes it suitable for a wide range of applications, including kitchenware, architectural panels, and automotive parts.

Compared to other stainless steel types, steel 304 offers an optimal balance between density, strength, and corrosion resistance.

To ensure quality, the density of steel 304 is rigorously tested using advanced laboratory equipment like spectrometers.

International standards and regulations guide the production of steel 304, considering its density and other mechanical properties.

Steel 304's density and composition make it recyclable, reducing its environmental impact.

Technological advancements are continually being made to enhance the density of steel 304 and its applications.

Understanding the density of steel 304 is essential in material selection and plays a vital role in various industries, from construction to manufacturing.

The steel density kg/m3 is a vital aspect of construction engineering. Knowing the density of steel in various forms helps in selecting the right materials.

Choosing the appropriate steel depends on its density, affecting its strength, weight, and application.

Different construction methods require various steel densities. Skyscrapers might demand high-density steel, while residential buildings might use lower density steel.

Understanding the steel density kg/m3 helps determine the load-bearing capacity of structures.

The density of steel in kg influences the cost. High-density materials might be costlier but offer increased durability.

Utilizing steel with the right density contributes to sustainability by optimizing material usage.

Quality control involves rigorous testing of steel density using techniques like spectrometry.

The construction industry adheres to global standards regarding steel density, ensuring safety and quality.

New technologies are enhancing our understanding of steel density and its applications in construction.

Choosing the appropriate steel density can also lead to environmental benefits, like energy efficiency in buildings.

The density of steel kg/m3 plays a crucial role in the construction industry. It affects everything from material selection to cost, quality, sustainability, and regulations.

The density of steel in kg is influenced by various elements added to the base metal. The composition defines the specific characteristics of the steel.

Different elements like carbon, manganese, silicon, and others can affect the density of steel.

| Element | Effect on Density |

|---|---|

| Carbon | Increases |

| Manganese | Increases |

| Silicon | Decreases |

Understanding how elements influence density is essential for applications like construction, automotive, and aerospace.

The controlled addition of elements during manufacturing allows for the fine-tuning of the density of steel in kg.

The quality control process ensures that the density remains within specified limits, affecting strength, flexibility, and other properties.

Understanding how elements affect density also has environmental implications, like recyclability and energy efficiency.

International standards guide the composition and density of steel, ensuring consistency and quality across industries.

Ongoing research is exploring new ways to manipulate density by altering the composition, leading to innovative products.

Understanding the density of steel in kg helps in safety measures, particularly in industries like construction and transportation.

The density of steel in kg and its relationship with various elements is a complex but essential aspect of modern industry. It affects everything from manufacturing to environmental sustainability.

Grasping the density of steel formula is pivotal for engineers, metallurgists, and researchers. This formula helps in predicting material behavior and is essential for design and manufacturing.

The density of steel formula typically relies on the mass and volume of the material. It can be expressed as:

[ \text{Density} = \frac{{\text{Mass}}}{{\text{Volume}}} ]

The density of steel formula plays a key role in engineering, especially in structural design, where accurate material specifications are vital.

Educators and students must understand this formula, as it is foundational in fields such as physics, materials science, and engineering.

Advancements in technology have allowed more precise calculations of density, influencing the development of new materials and manufacturing methods.

Understanding the density of steel formula aids in quality control processes, ensuring that materials meet specific industrial standards.

The application of this formula contributes to sustainability by allowing the optimal use of materials, minimizing waste.

International norms guide the application of the density of steel formula, ensuring consistency and reliability across different regions.

The density of steel formula is more than a mathematical expression. It's at the heart of many industrial applications, educational curricula, and technological advancements. Understanding it unlocks the full potential of steel in our modern world.

Mild steel density is an important consideration in material selection and application. It offers unique properties that make it a versatile choice for various industrial applications.

Mild steel is made primarily of iron and carbon. Its density typically ranges from 7850 to 7900 kg/m3 (density of mild steel in kg/m3).

Compared to high-carbon steels, mild steel has a lower density, offering flexibility and weldability.

The unique density properties of mild steel make it a preferred choice for automotive bodies, construction materials, and machinery.

Careful control of the carbon content and other elements leads to the specific density of mild steel, affecting its mechanical properties.

Stringent testing of mild steel density ensures adherence to global standards, providing reliability and consistency.

Mild steel's density and composition make it recyclable and contribute to environmental sustainability.

Ongoing research into mild steel density is leading to new formulations and applications, driving innovation in various fields.

Understanding mild steel density is crucial in many industrial sectors. Its versatility, combined with responsible manufacturing and quality control, provides a material that meets diverse needs.

The density of carbon steel changes across different grades. This variation impacts its mechanical properties and applications.

Various grades of carbon steel exist, each with a unique density. High-carbon steel has a higher density, while low-carbon steel (such as mild steel) has a lower density.

| Grade | Density (g/cm3) |

|---|---|

| High-Carbon | 7.8 |

| Medium-Carbon | 7.7 |

| Low-Carbon | 7.6 |

The density of carbon steel influences its hardness, strength, and ductility, affecting its suitability for specific applications.

Different grades require unique manufacturing processes, affecting the final density and properties of the carbon steel.

The varied density across grades of carbon steel defines its usage in industries like automotive, construction, and tools manufacturing.

Precision in controlling the density of carbon steel ensures that the material meets industry standards and performance requirements.

International regulations govern the density of carbon steel, ensuring consistency and quality across markets.

Understanding and controlling the density of carbon steel is vital for responsible manufacturing, including considerations of recycling and resource efficiency.

The density of carbon steel across different grades is a complex but vital aspect of materials science. It guides everything from manufacturing to application, ensuring that the right material is used for the right purpose.

The steel density g/cm3 is a standard measurement in metallurgy. It's vital for understanding the material's characteristics and performance.

Steel density is often measured in g/cm3. This uniform measurement facilitates comparison and application across various domains.

Knowing the steel density g/cm3 helps in selecting the right material for specific applications, ensuring optimal performance.

Density directly correlates with other steel properties, such

as hardness and tensile strength, making it a key consideration in metallurgy.

Modern technology allows for precise measurements of steel density g/cm3, enhancing material development and quality control.

Global standards define how steel density g/cm3 is measured and applied, ensuring uniformity and reliability in the industry.

Measuring steel density in g/cm3 aids in sustainable practices by optimizing material usage and recycling processes.

The steel density g/cm3 measurement is essential in metallurgy, shaping how materials are developed, applied, and managed. Its significance spans across industrial, educational, and environmental domains, reflecting the material's central role in modern society.

The density of stainless steel 304 is a key factor that contributes to its widespread use in various industries. Understanding this density allows professionals to utilize the material to its full potential.

Stainless steel 304 is renowned for its corrosion resistance, strength, and formability. Its density is typically around 8.0 g/cm3 (density of stainless steel 304).

Compared to other stainless steel grades, 304 offers a balanced density that provides excellent performance without sacrificing ductility.

The density of stainless steel 304 makes it suitable for kitchen appliances, automotive parts, and construction materials.

Accurate control of density in stainless steel 304 is essential during manufacturing, as it affects the material's mechanical properties.

Advanced testing methods ensure that the density of stainless steel 304 is within desired specifications, maintaining quality and reliability.

International norms guide the measurement and application of density in stainless steel 304, fostering consistency across markets.

Understanding and controlling the density of stainless steel 304 supports eco-friendly practices, such as recycling and efficient material usage.

The density of stainless steel 304 plays a central role in defining its characteristics and applications. From manufacturing to end use, this density value shapes how the material is perceived and utilized in various fields.

The density of mild steel in kg/m3 is a critical measurement that influences its various applications in different industries. By understanding this density, engineers and manufacturers can optimize material use.

Mild steel's density usually ranges between 7850 to 7900 kg/m3. This density of mild steel in kg/m3 contributes to its unique mechanical properties.

The density of mild steel in kg/m3 affects its strength, ductility, and weldability, shaping its use in various applications.

Understanding the density of mild steel in kg/m3 facilitates its comparison with other materials, guiding material selection.

The density of mild steel in kg/m3 makes it a preferred material for construction, automotive, and machinery applications.

Controlling the density of mild steel in kg/m3 during manufacturing is crucial for achieving desired material characteristics.

Regular testing of the density of mild steel in kg/m3 ensures that it meets industrial standards, providing consistency and reliability.

Awareness of the density of mild steel in kg/m3 aids in sustainable manufacturing, including recycling and energy efficiency.

Continuous research into the density of mild steel in kg/m3 leads to new alloys and applications, fostering innovation.

The density of mild steel in kg/m3 is not just a numerical value; it's a critical parameter that defines its characteristics and applications. From industry to research, this measurement plays a vital role in shaping our modern world.

The exploration of steel density in its various forms and applications underscores its importance in today's industrial landscape. From mild steel to stainless steel 304, understanding the density allows for innovation, quality control, and sustainability. Embracing the insights into the density of steel propels us toward a future where materials are optimized for performance, efficiency, and environmental stewardship. Whether it's the precision of a specific formula or the characteristics of a particular grade, steel's density continues to inspire and drive progress across multiple fields.