Myriad manufactures high-quality 300 Series Stainless Steel with Grade SUS 301 Stainless Steel series, which include aisi 301. The company manufactures and tests its products in factories and laboratories. With 25 years of good reputation, the company ensures the quality of products they manufacture.

Many customers like you purchase SUS 301 stainless steel from us, and many of them have high requirements for hardness and tensile strength. The high tensile strength 301 ss produced by Yaoyi is very suitable for the production of constant force springs: U SPRING, V SPRING, and ABS brake systems.

Myriad provides you with high-quality 301 stainless steel service. 1/2 hard is the hardness range that Mriad is best at. You can rely on us and we will provide you with reliable stainless steel raw materials.

If you’re new to the stainless steel trade, the chances are that you’ll initially encounter confusion here and there. Stainless steels, although they may appear all similar on the outside, have hidden numerous differences. These differences spring from their chemical composition and performance, which results in different grades.

Aside from that, the metallurgists have a habit of giving odd names, which is undeniably perplexing to non-specialists. In particular, the SUS stainless steel series is one incarnation of this bad naming habit. With this, allow this article to help you figure out the SUS series, specifically the SUS 301 Stainless Steel Grade.

We have already prepared FAQ for you. If you have any questions, you can tell us for help.

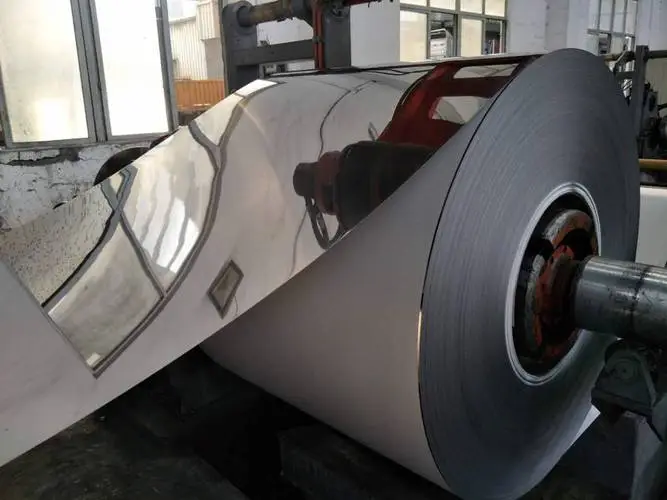

301 stainless steel coil is a semi-finished product produced from hot-rolled coils. It can be used to produce 301 stainless steel pipes, 301 stainless steel plates, and can also be directly used in the production of springs, clamps and other industries. The 301 stainless steel produced by Yaoyi and downstream stainless steel pipes can provide high-quality services for your products. At the same time, the 301 stainless steel coil produced by YAOYI is also particularly suitable for the elastic material industry, such as constant force springs, automobile ABS, clamps and other industries that require the elasticity of raw materials.

We purchase stainless steel hot-rolled coils and also sell high-quality stainless steel coils to you. We purchase high-quality 301 stainless steel hot-rolled coils, so we also provide you with cost-effective aisi 301 stainless steel cold-rolled coils. At the same time, we cooperate with downstream stainless steel pipe factories to provide you with high-quality 301 stainless steel pipes and provide you with one-stop service.

Produce thickness 0.02mm~20mm cold rolled 301 ss coil.

We can cut out the stainless steel plate of the specifications.

We can cut out the stainless steel plate of the specifications.

AISI 301 stainless steel is most vulnerable to cold deformation in traditional austenitic stainless stones. The hardness of his work is very high. For any increase in cold work, tensile strength and yield strength will significantly increase. For structural parts like angle steel and channel pieces, which should be additionally strong and rigid after manufacture, reactions to work hardening are especially significant.

In austenitic alloys with a greater nickel content particularly types 304, 304L, and 305, however, lower hard work rates for deep drawing applications are generally preferred.

Moreover, the AISI 301 Stainless Steel has excellent ambient resistance to corrosion but is poorly resistant to corrosion in media and the reduction of chemical media such as acids, alkalines, and salt. AISI 301 steel is used mostly for higher loads in cold working conditions and also for reducing the weight of devices and corrosion-resistant components.

In normal settings, most alloys in stainless steel have strong to glorious corrosion resistance. Stainless steel alloys are likely to have the name “stainless” steel, which is a durable, albeit skinny, oxide layer which prevents rusting. The physical and chemical characteristics of chrome steel AISI 301, 302, and 304 which we always inventory – including the conditions for free bending for each alloy. Rate AISI 301L, which is the low carbon AISI 301 grade, is the best option for strong ductility applications.

This means that, in comparison to an analog basket made of 304-grade alloy, a basket made of steel grade AISI 301 would bring up to 33 percent stress higher at room temperature. It is a suitable material for various uses for both industrial and consumer products, due to its mécanical and physical characteristics.

Furthermore, it can maintain sufficient ductility even during 1⁄2 difficult circumstances by subjecting Grade AISI 301 to a controlled examination. This grade AISI 301 type may also be used in ships, trains, and architectural buildings.

Initially, Yaoyi’s 301 stainless steel coils are made in sheets, which are then converted using a Z mill to transform the sheet into a coil before further rolling. These broad coils are usually constructed at 1250mm (sometimes a little wider) and are called mountain coils. Moreover, 301 stainless steel coils are further processed with the help of a number of manufacturing procedures, such as sliding, in which the wide coil slides in many strands. In Yaoyi, 301 stainless steel foils form a batch after splitting and several various names including strip coils, slit coils, bands or simply strips. A cold work can obtain great strength and ductility with stainless steel coil type 301. In the rinsed form, following cold processing, the 301 stainless steel belt is magnetic, but not magnetic. Thanks to its exceptional strength and corrosion resistance as Yaoyi offers, this grade of stainless steel is suited for numerous applications.

Why Choose Yaoyi to do the Stainless Steel Edging?

The 301 is an austenitic stainless steel nickel chromium which can produce high strength and cold working ductility. The thermal processing is not hardy. In the annealed form, stainless steel type 301 is non-magnetic and magnetically cold. In cold working conditions, this chromium nickel alloy provides a high strength and excellent Ductility.

The 301 stainless steel coil is made of colored and annealed chromium nickel. This provides the maximum degree of stretch-formability in the additive state of every stainless steel, and the highest strength level in the heavily cold working condition is in all 300 series. In the annealed condition, 301 stainless steel coil is not magnetic but is magnetic due to cold work.

In many settings, Myriad’s 301 stainless steel coil is resistant to corrosion, however the propensity to carry corrosion is less than stainless steel of 304/304L. Type Myriad’s 301 stainless steel coil is not applicable to welding because of its lower CO2 concentration and the susceptibility to carbide precipitation restricts the use in some applications.

Furthermore, data are typical, and should not, as supplied for instructive reasons, be considered to constitute maximum and minimum values of the specification or final design. The data can be updated at any time without notification. Real information on any particular product or material may differ from that presented herein.

Stainless Steel Cable Ties – YAOYI Stainless Steel

Myriad’s 301 stainless steel coil is extremely marketable, due to its great resistance to corrosion and abrasion, its quality of forming and drawing, weldability, strength and ductility. Heat treatment is hardy only, as all the high chromium nickel stains, and not cold working. It is in the recessed state non-magnetic but this Yaoyi type of stainless steel coil with gradual cold functioning becomes slightly magnetic. This includes airplane components, architectonic reinforcement, automotive trim and wheel covers, building components, high temp, light-heating structural components, drainage roofing, thermostating equipment and transport equipment.

On the other hand, most common style of bucket is known as a pancake coil. It is named for the way the buckle looks when lying flat. The ‘Travers’ or ‘Oscillated’ form of winding is also called the coil wound and the ‘spool’ as it sometimes looks like a cotton coil that might be physically wounded on a plastic bobbin.The manner in which spindles are wound can give them different names. This enables coils to be made significantly larger and leads to enhanced stability and higher production performance.

Myriad’s 301 stainless steel coil is cold worked to provide excellent strength and ductility. Like the 201 stainless steel type, 301 stainless steel coil is non-magnetic and magnetised, as cold work is on the increase. However, it is ultimately just a bit more magnetic than other common stainless austenitic steels.

Why Does Stainless Steel Rust?

The chemical composition of Yaoyi 301 stainless steel coil percent is: max. carbon 0.15; max. of manganese 2.00; 0,045 of phosphorus; max. of softness; 0.031 of sulfur; 16.00 to 18.00 nickel; max. of nitrogen and max. of 0.10 of iron; and max. of iron balance.

Thus, the chromium content of Yaoyi’s stainless steel coils and in some circumstances nickel are separated from carbon steels. When nickel is added to chromium stainless steel it improves its mechanical characteristics, for example its density, heat capacity and resistance. The addition of chromium to carbon steel is more rusty and stainless. In the production of machinery, tools and containers, for example, steel sheets are employed.

The physical characteristics are: 285 lbs/in3 7.88 g/cm3. Microhm-in (microhm-cm): 68 degrees F (20 °C): 27.4 (69.5), Permeability of the magnet (MP): H = 200 Oersteds: 32 degrees F (0,12 degrees F): Melting ranges between: 2250 and 2590° F (1399-1421 degrees C).

Thus, the chromium content of Yaoyi’s stainless steel coils and in some circumstances nickel are separated from carbon steels. When nickel is added to chromium stainless steel it improves its mechanical characteristics, for example its density, heat capacity and resistance. The addition of chromium to carbon steel is more rusty and stainless. In the production of machinery, tools and containers, for example, steel sheets are employed.

Yaoyi: The Expert of Stainless Steel

Increased carbon and nickel levels of Myriad’s 301 stainless steel coil support good design quality. This composition, however, marginally weakens its corrosion resistance.

Hence, the corrosion prevention needs secondary cleaning of Myriad’s 301 stainless steel coil. The secondary step dissolves the carbide of chromium and removes the discoloration from the soil by restoring 301 stainless steel coil solder or laser-cut resistance. In addition, Yaoyi’s 301 stainless steel coil is a type 304 modifier that reduces the concentrations of chromium and nickel. This enables the cold work hardening range to be achieved by a roll, with simultaneously reduced ductility loss than with type 304.

Myriad manufactures and distributes high quality, valuable stainless steel products to assist our customers achieve their goals and even overcome them. We may supply different materials and forms and rely on us to do so on a timely and speculative basis.

What Would Cause Stainless Steel To Rust?

In a base oxygen furnace (BOF) or electric bowl, Stainless steel begins to be created by mixing with minimum carbon quantities (EAF)

Then, molten steel, called a warm strip, is poured into sheets reduced to smaller strips of steel. The steel mills are increasingly using a new, highly successful procedure called direct reduction of “Hot Tape.”

The heated band is turned back into “cool rolling steel” in the process of stainless steel finishing. The galvanizing process provides a zinc protective layer. “Coil” is the ultimate product.”

As such, the strap is separated in widths which correspond to the predicted sizes of the end product to turn the strap into cold forming components in a steel frame.

Following, the cold-shaping metal split spools are usually created by rolling the steel into a C-sections sequence and into different forms. The penetration of the plumbing and electrical running at predetermined areas also decreases installation time. No heat is essential for the shape (as opposed to hot-rolled steel) and thus the term cold steel. A wide variety of structural and non-structural applications cover a range of steel thicknesses.

On the side, wall and floor panels as well as roofs are then produced with cold-shaped stainless steel frames or are bundled to the worksite.

Cold form steel, for its low weight, resistance, non-combustible nature and ease of mount, is the dominating substance for the curtain walls and partitions in commercial buildings. For the same reason the primary structural system is increasingly utilized for structures up to nine floors.

Finally, stainless steel does not corrode, rust or discolor rapidly, like other steels, due to water exposure. Typically, unprotected carbon steel rusts when exposed to air and humidity.

The Difference Between Hot and Cold Rolled Stainless Steel

Myriad’s 301 stainless steel coil has good to outstanding resistance to corrosion and is similar in grade 304 utilized in a variety of food services.

The strength of the type 301 stainless steel spindle against corrosion in light service circumstances is comparable to that of the type 302 and 304 resistance. Corrosion, food, juices, and salt resistance to the atmosphere is excellent for de-icing on the road. The best corrosion resistance is achieved in the rectified state.

What is The Difference Between Cold Rolled and Hot Rolled?

In addition to the actual composition of metal, stainless steel coils can be cut down to length, depending on your application and vary in thickness and flexibility.

Thus, 301 stainless steel is a change to grade 304 stainless steel with lower grade chroma and nickel in order to expand the work hardening range. Corrosion resistance equivalent to Type 302 and 304 is observed in steel type 301. In cold working and cooling circumstances Type 301 achieves its best resistance to corrosion. Types 302 and 304 are chosen in temperate settings, as higher extension (attainable on a certain strength level) facilitate the production.

It is also extremely crucial, depending on your environment, that the information about your application is communicated to your manufacturer so that your stainless steel coil can reliably be resistant to your unique condition, so that it can continue to operate well for years to come.

1.Annealing and descaling hot rolling.

It is utilized in applications that do not require a smooth decorative finish. Cold rolling, clothing and descaling finish produced. A lightweight pass with finely polished rollers creates a bright finish. For weakly formed applications where a bright finish in the formed part is required. Strip, foil and ribbon are available.

2.Cold-formed

Myriad’s 301 stainless steel coil is ductile and easy to shape, but severe or numerous operations can require interim anneals because of the high rate of work hardness. Its strength and hardness make it suitable for structural purposes. Normally drawn or stamped.

3.Temperature resistance

For intermittent services up to 840 °C and for continuous service up to 900 °C, Grade 301 has strong oxidation resistance.

4.Heat Treatment

The heat treatment for Yaoyi’s stainless steel coil is not hardenable.

The Heat is at a temperature of 400 – 900 °F (260 – 482 °C).

Rinse: heat to 1038 – 1121°C, heat to 1900 – 2050°F, then dry.

Relief of Stress Air: heat up to 260-482°C, then cool air, to 500 – 900°F.

5.Forming

The Myriad301 stainless steel coil can be formed and drawn. During harsh drawing and training operations, interim rinsing may be required due to its high rate of resistance to work.

6.Welding

The 301 stainless steel coil of Myriad is the same as the most common 18-8 alloys, which are of a similar welding capacity. The fundamental difference is that the C% of the alloy promotes rapid corrosion in some areas affected by solder heat. When filling is necessary, AWS E/ER 308 is most commonly indicated.

The Guide Of American Stainless Steel Tube Standard

In several situations or temperatures, this extreme power grade of steel is usable. Type AISI 301 is austenitic stainless steel that offers good strength and ductility while chilling in nominal compositions of 17 p.c. and 7 percent nickel. In Full Hard, Half Hard, and 1/4 Hard settings, United Performance Metal offers as well AISI 301.

In slightly corrosive conditions at ambient temperatures, this grade shows good corrosion resistance. This hot-warming feature is not treatable and is non-magnetic as curd, but after cold working is mildly magnetic. Form AISI 301 has excellent resistance to heat and corrosion and quick welds. In 1/4 rough, half of tough, 3/4 tight, and absolute onerous temperatures, PSW stocks Type AISI 301 stainless steel. This is due to chrome carbide accumulation that depletes chromium in colder areas.

Also, it has a useful impact on mechanical characteristics and some corrosion forms. More chromium-containing substance gives further resistance to corrosion. Grade 304 chrome steel, by comparison, can only strain up to 90 ksi before mechanical failure.

Besides, stainless steel is an austenitic formed in wrought materials for key shaping purposes. The chemistry of this alloy enables the best mechanical properties to be combined for specific applications. For example, the Full Hard would sustain a minimum elongation of 9% by 2″ as opposed to approximately 2% with the Type302 Full Hard. The continued elongation on the part of Type AISI 301 is due to its pleasant hardness, durability, and superior fatigue life.

Therefore, the shape will at a bend factor diameter multiplied by the thickness of the steel. The AISI 301 chrome stele composition is noteworthy for maintaining relatively excessive quantities of nickel (Ni) and chromium among manufactured stainless steels (Cr).

AISI 301 Stainless steel sheets with dimensional characteristics

The applicable millimeter thickness for this AISI 301 Stainless Steel varies from 0.2 and 4.75 while the millimeters diameter varies from 600 to 1200 and varies according to consumer requests in different slit shapes.

1.Coils Milled

2.Coils Splitted

3.Plate & Tablets

4.Bar Round

How to Remove The Oxide Scale on The Surface of Stainless Steel Casting Billet?

1.The normative definition of the mean carbon percentage is 0.15.

2.The norm specified maximum percentage of manganese is 2.

3.The norm specified maximum percentage is 0.045 Phosphorus

4.The standardized 0.03AISI 301-stainless chemical composition is the highest proportion of sulfur

5.The normal optimum proportion of silicon is 1

The standard specified limit of chromium is 18, while the standard defining minimum of chromium is 16.

Besides, in a cold-rolled condition, rather than a glued shape, the AISI 301 varieties have the best corrosion resistance. This degree is not hardened by clothing, but more hardened by cold, cold rolling. This form hardens at a higher rate during cold rolling. Training like all classes in the family is daunting to attend.

Therefore, austenite structures are converted to martensite during strain hardening. Any problems are caused by the soldering when the substance in the area hit by the heat loses temperature. Spot welding with AISI 301 forms is typically used.

1.Its temperature ratings are of half hardness, quarter hard temperature, and absolute hard temper.

2.The power of the tensile is 185 mph in some technical references for the maximum hard classification.

3.For the whole hard grade in some technical references, the yield intensity is 140Mpa.

4.The elongation in 50mm is 9% for the whole hard grade.

How do you care of stainless steel?

1.A similar substance in JIS is called steel type SUS AISI 301.

2.The same material with a DIN standard is called steel 1.4310.

3.The analogous material in the UNS standard is called steel type SAISI 30100.

1.Appliances & Utensils for Cooking

2.Railway structural components

3.Car parts Car parts

4.Components of aircraft building

5.Many other commercial applications

AISI 301 steel is almost equivalent to 304 stainless steel in mild conditions with high corrosion resistance. Resistance in food and the environment can be described as amazing. It will withstand stress fractures, as in the case of 304 degrees.

On the other hand, 316 stainless steel will replace AISI 301 steel style in complex realities. When higher protection against corrosion and less job hardening phenomenon is needed, 3201 may be the optimal grade for work.

Comparison of Stainless Steel Standards in Different Countries

First, to use the material you choose would ensure that you have a personalized basket, or rack that lasts for several years and that starts to fall apart in only a few uses whether you make custom-made wire basks for handling, washing of the pieces, or some other use.

Therefore, for a broad variety of uses, many manufactures use metal alloys like stainless steel. Although laymen are widely found in stainless steel, many do not know that there is a wide range of stainless steel types, such as grades AISI 301 SS or 304 SS.

Although both AISI 301, as well as 304 stainless steel, use iron as their main ingredient, the two alloys have several key chemical differences, all compounds in the two steel alloys are limited to the same values. Yet stainless steel grade 304 gets more chrome and nickel than stainless steel grade AISI 301. This continues to increase the cost of rank 304 to rank AISI 301.

Most stainless steel alloys are fine to good under natural conditions for corrosion resistance. The layer of oxide which avoids rusting, hence the name of steel “stainless,” tends to be solid, but thin.

The corrosion tolerance of grade AISI 301 and grade 304 stainless is not so different in mildly corrosive conditions at regular ambient temperatures. In general, Grade AISI 301 is much less resistant to corrosion than Grade 304 because its content is lower in chromium and its carbon content is higher.

The variation in corrosion resistance at higher temperatures is more marked.

The strain that can be applied by each other before a mechanical breakdown is another key distinction in the Deux grades of stainless steel.

AISI 301 is also more efficient and carbon-intensive for mechanical stress. stainless steel 0.15 percent compared to 304 percent 0.08 percent by weight. In-room temperature conditions, AISI 301 grade Stainless can take up to 120 ksi kilopounds per square inch.

In contrast, stainless steel grade 304 will only take up to 90 ksi of strain before mechanical failure occurs. This means that a basket made of AISI 301 Grade rubber will bear up to 33% more stress at room temperature than a comparable case made of 304 Grade alloy.

Staying within Yaoyi’s 301 stainless steel coil specification, a wide range of product completions with distinct designed material qualities for specific applications might result in various chemical composition and process changes.

Ready to form and be drawn, in some forming, the applications 301 stainless steel coils may not be correct. This applies in particular to those which require several training operations.

It is important to note that the material is generally utilized in the subway trains, structural components of airplanes, trailers, auto trims and car wheel coverings. It is also utilized in the manufacture of drainage products, conveyors and door frames for storms. Yaoyi’s 301 stainless steel coil is a versatile rating, excellent for a variety of applications.

As in a variety of industries, stainless steel is commonly employed as a corrosive, rust-resistant and stainless steel as other metal types.

Grade 301 Stainless Steel is usually for fabrications requiring high strength, high corrosion resistance, and good elasticity (cold worked). Therefore, it is excellent for applications where you need good steel strength in mildly harsh conditions. Also, some of the best applications of aisi 301 are as follows:

1.Making structural elements for rail cars

2.Parts of an airframe

3.Parts of a highway tractor

4.Wheel covers for cars

5.Clips and holders for wiper blades

6.Clips for stove elements

7.Frames on a computer

8.Spring-loaded toaster

9.The use of curtain walls

4 Common Methods for Welding Stainless Steel Pipe

Myriad offers aisi 301 stainless steel in forms ¼ hard, ½ hard, to the full hard tempering. You may also check on the work hardening section for the specific property values.

The company always takes extra steps in ensuring they deliver quality products. Myriad conducts numerous tests from manufacturing to delivery to check that they are high-quality steels for their clients. Also, they conduct these assessments to conform with international regulating bodies for standard material specifications like the ASTM International and stipulates as follows.

Study Stainless Steel Technical Made Simple: A Step-by-Step Guide

All metallurgy works are made to answer specific needs and conditions. Stainless steel, in particular, comes in wide arrays of types and specifications. It is important to understand which requirements you want to address and choose the compatible material for it. Knowledge and understanding of the material will prevent you from overspending or using materials below the standard needs.

In this section are the properties, composition, and specifications of a grade 301. You may use this part as your reference to the aisi 301 ss applications. Generally, stainless steel is characterized by Chromium for corrosion resistance and Carbon for tensile strength. However, there is more than just these features.

Check the tables below for your reference. You can also check its highlights and downsides to maximize its potential as a material. Kindly note that values are tested at a fixed temperature of 23 °C, except those indicated otherwise. All specifications and properties are based on ASTM International ASTM A240.

Grade 301 has a density of 7.9 – 8.2 g/cm3.

|

Element |

Allowable Percentage (%) |

|

Carbon (C) |

≤ 0.15 |

|

Chromium (Cr) |

16.0 – 18.0 |

|

Manganese (Mn) |

≤ 2.0 |

|

Nickel (Ni) |

6.0 – 8.0 |

|

Phosphorus (P) |

≤ 0.035 |

|

Silicon (Si) |

≤ 1.0 |

|

Sulphur (S) |

≤ 0.03 |

FOCUSED ON THE 0.03 ~ 0.05 mm Stainless Steel Foil

|

Property |

Value |

|

Elastic Modulus |

195 GPa |

|

Elongation A50 |

40% |

|

Hardness Brinell |

≤ 187 |

|

Hardness Rockwell |

95 |

|

Poisson’s Ratio |

0.3 |

|

Shear Modulus |

77 GPa |

|

Tensile Strength |

515 MPa |

|

Yield Strength Rp 0.2 |

≥ 205 MPa |

The aisi 301 stainless steel on annealed form showcases 120 kilopounds per square inch ultimate tensile strength. It has a yield strength of 45 kilopounds per square inch on a 0.2% minimum application under similar conditions. Furthermore, it scales 60% of elongation in two inches, with a Rockwell hardness scale of B86.

As a rule of thumb, there are ways to check out the mechanical strength of stainless steel by its carbon content. For example, grade 301 has 120 ksi UTS while 304 only has 90 ksi UTS on standard room temperature. Therefore, it implies that grade 301 can provide more tensile strength than grade 304. You can check these properties to compare different grades which you might need depending on your application.

Why do you Purchase the Stainless Steel Flat from Yaoyi ?

|

Property |

Value |

|

Coefficient of Thermal Expansion |

1.7E-5 – 1.9E-5 1/K |

|

Melting Point |

1230 – 1480 °C |

|

Specific Heat Capacity |

440 J/(kg•K) |

|

Thermal Conductivity |

11 – 21 W/(m•K) |

|

Property |

Value |

|

Electrical Resistivity |

8.5E-7 Ω·m |

Stainless steel is always known for its corrosion resistive properties. Besides, this property became possible by infusing Chromium in its steel composition. The invention of stainless steel opened new steel use possibilities in harsh weather conditions, food service, and medical equipment.

In particular, aisi 301 Stainless Steel has an excellent corrosion resistance property. Besides, it passes typical requirements for both foodservice safety standards and atmospheric corrosion. Thus, it makes an ideal material for eating utensils and aircraft structural components, respectively.

Grade 301 can attain optimal corrosion resistance by cold working and then anneal it. Carbide precipitation can occur in the absence of subsequent annealing when subjected between the temperature ranges of 800 – 1600 ⁰Fahrenheit. This reaction may result in intergranular corrosion. By comparison, it exhibits corrosion resistance akin to Grade 302 and 304 within a relatively corrosive environment.

Stainless Steel Type 301 can be exposed up to 1600 ⁰F (871 ⁰C) without significant oxidation. Meanwhile, it can withstand up to 1450 ⁰F (788 ⁰C) of temperature exposure within intervals. Technically, stainless steel cannot rust being infused with Chromium under typical conditions.

Grade 301 Stainless Steel does not harden through heat processing. It best attains its optimal properties using the following heating process:

STAINLESS STEEL APPLICATION OF STAINLESS STEEL WASHER

Grade 301 Stainless Steel is formidable for its high yield strength and hardness for structural applications. The company obtains these properties through processes of cold-working. Grade 301 has 110 kilopounds per square inch minimum tensile strength on normal conditions. Also, tempering processes can further increase this tensile strength up to 185 kilopounds per square inch on its “full-hard” condition.

Formability is the steel’s property to form into different shapes, punctured, or rolled without breaking or “cracking.” Moreover, it is among the vital properties of steel, allowing it to form into different shapes to fit specific uses.

Grade 301 Stainless Steel exhibits great formability properties. It can easily be formed and drawn. Although, this grade may need intermediate annealing for intense forming applications. Similarly, grade 301 may not be the most viable option for complex forming operations entailing multiple processes.

Weldability is the ability of metals to be fused or weld with similar materials. This type of joinery is one of the modern conventions in metallurgy. Construction sites also use this stainless steel type for structural components or where mechanical joinery is impractical.

In general, the austenitic type of stainless steel is highly weldable by conventional welding processes. Similarly, Grade 301 stainless steel is considered to have the same weldability as grade 304L. However, it might require special considerations to prevent “hot cracking” by ensuring the ferrite is formed within the weld deposit.

The American Welding Society’s (AWS) E/ER 308 is recommended when a weld filler is needed. You may also check similar fillers with the same properties as mentioned above.

Grade 301 Stainless Steel is classified under the following specifications:

You may always refer to these codes to check further applications of Grade 301 Stainless Steel.

Yaoyi provides different steel grades to fit your specific applications. We are your one-stop shop for steel manufacturing. You can check the best steel for your applications by checking its properties or contacting us for assistance. It will be our utmost pleasure to offer you their expertise.

Manufacturers name stainless steel based on the abbreviation and grade codes their composition is under. The numerical name 301 stands for a particular composition and performance under international standards.

On the other hand, the “SS” and “SUS” are two examples of abbreviations in stainless steel. As you might have guessed, “SS” stands for “stainless steel.” Meanwhile, the “SUS” stands for “stainless use steel.” You might wonder, what’s the difference?.”

The short answer is nothing. The SS 301 and SUS 301 are simply the same steel grade with different names. However, it is also worth noting the factors that differentiated them, which are:

These stainless steel grades are typically uniform worldwide. However, minute differences may still exist from different manufacturers across countries.

How to Buy Stainless Steel Coil Springs Raw Material?

After we clarified the naming confusion, it is now easier to understand that all 301 grades are the same. To identify SUS 301 among other grades, we have to look into its intrinsic properties and performance values. By understanding the following, we can find out how and where to use SUS 301.

Like most of the stainless steel grades, SUS 301 is a chromium-nickel austenitic stainless steel. Chromium-nickel stands for the two prominent elements in its composition. Chromium, in particular, accounts for the “stainless” characteristic of the steel.

Meanwhile, austenitic is among the five internal structures stainless steel is built from. Austenites are face-centered cubics that are the result of the steel’s chemical composition. Chromium-nickel-based alloys typically produce this kind of austenitic structure.

Manufacturers desire stainless steel for its high corrosion and oxidation resistance. This property is attributed to its Chromium resistance. Specifically, SUS 301 has a 16-18% Chromium content. This content is higher than the minimum requirement of 10.50% minimum threshold to be categorized as stainless steel.

SUS 301 exhibits an average density of 7.93 g/m3. The austenitic structure also makes it non-magnetic on the basic annealed form.

The typical market finish comes in 2B or smooth reflective finish. The surface finish may differ depending on availability – do note this to avoid confusion when encountering other finishes. Matte surfaces do exist, but manufacturers rarely produce this type, and the market demands do not favor it.

The chemical properties, although hidden from the naked eye, is a fool-proof distinction of a grade. For SUS 301, it is comprised of the the following chemical composition:

Carbon (C) = 0.15% max

Manganese (Mn) = 2.00% max

Silicon (Si) = 1.00% max

Phosphorus (P) = 0.045% max

Sulfur (S) = 0.03% max

Chromium (Cr) = 16-18% max

Nickel (Ni) = 6-8% max

Stainless steel has relatively lower carbon contents than carbon steel. Thus, the strength capacity is limited by the amount as regulated within the grade. Nevertheless, it is still durable steel capable of exhibiting remarkable strength thresholds.

In SUS 301, it has a yield strength of 205 N/mm2 and a tensile strength of 520 N/mm2. Additionally, it exhibits an elongation of 40% and a hardness of 95 Rockwell (HRB). These numbers shall be your reference for engineering the material for strenuous applications.

SUS 301 exhibits an excellent welding capability. However, it would help if you considered certain precautions for intense welding operations due to the risks of carbide precipitation. Carbide precipitation happens when carbon reacts with chromium due to extreme temperature resulting in adverse effects on corrosion resistance.

You might want to consider the low carbon or “L” variants of the grade for intense welding. Ferritic stainless steel also welds better, albeit they have lower corrosion resistance. It’s up to your discernment to weigh out factors defending on application. You may always

consult your local manufacturer or professional when in doubt.

SUS 301 can withstand almost an average forming or drawing process. Just be considerate about multiple forming operations which can damage the steel.

Another distinct characteristic of SUS 301 is its incapacity of being heat treated. This aspect is due to its austenitic structure. No strength can be gained using heat treatment.

These properties are the standard for SUS 301. There might be small differences depending on region, but this will be limited to little variation in composition and performance. For sensitive operations, you may always consult your trusted manufacturer or professional for assurance.

A Complete Guide to J1 Stainless Steel

SUS 301 is perfect for applications requiring decent strength and high corrosion resistance under mildly harsh environments. Some of the best applications of SUS 301 stainless steel are:

Under typical circumstances, stainless steel is resistant to rust. However, certain conditions or threshold limits can still cause rust build-up. Some of these causes include the following:

It is also worth considering that SUS 301 has lower Chromium contents than the most common grade 304. Thus, it has a relatively lower corrosion threshold than the majority of the popular market supply. You may have to look for better grades if your application involves extremely harsh conditions.

Another characteristic of austenitic stainless steel is its non-magnetic property on annealed conditions. However, manufacturers can magnetize SUS 301 through a variety of methods in cold working.

This non-magnetic characteristic is also often a way to check whether your stainless steel is authentic. This fact is certain, at least for austenitic stainless steels like the 300 series.

Everything you need to know about SUS SS304

Grade 304 is the most common stainless steel supplied in the market. Thus, it makes a good benchmark of comparison for either stainless steel. There are but three elemental differences that distinguish SUS 301 and 304 between one another. These elements are carbon, chromium, and nickel, which account for various effects on the steel’s property.

SUS 301 has a higher 0.15% carbon content while 304 has a lower 0.08%. Carbon accounts for the steel’s strength properties. Therefore, SUS 301 is harder and more durable than 304. It is better suited for strenuous applications such as structural components.

Meanwhile, SUS 301 has a lower 16-18% chromium content while 304 has a higher 18-20%. As we have mentioned, chromium is what makes stainless steel corrosion resistant. Thus, lower chromium contents on SUS 301 entails lower corrosion thresholds compared to 304.

Furthermore, SUS 301 also has lower 6-8% nickel content while 304 has a higher 8-12%. Nickel primarily stabilizes the structure on austenitic steels. Thus, it is typically in direct proportion to the chromium content. If there is more chromium, manufacturers should use more nickel to stabilize the internal makeup.

It is also worth noting that chromium and nickel are high-value metals, making 304 more expensive than 301. In this matter of cost is where customers usually weigh out considerations.

Just be certain of your applications first, and then pick the most suitable option. That way, you can maximize the use of your investments with the most efficient grade. After all, the superiority of these stainless steel grades is just a matter of how you’re going to use them.

Everything you need to know about SUS SS304

This steel series is well-known for being austenitic. It implies that these are a strong arrangement of iron with cubic crystals. The best supporter of the compound in austenitic stainless steel is chromium and nickel. These stainless steels are not difficult to sustain. Furthermore, they can withstand extreme temperatures and are corrosion-resistant.

These grades of stainless steel have roughly 18% to 30% chromium and 6% to 20% nickel as their major alloying increases. The compounds of this series oppose decomposition while maintaining their solidarity at high temperatures.

The 300 series stainless steel resists more vulnerable bases like ammonium hydroxide. However, they turn powerless against drawing and breaking when presented to bases like sodium hydroxide. While this steel works well in humid or acidic conditions, different metals in touch with it experience galvanic corrosion.

These 300 series stainless steel are the most preferred products among the stainless steel family. Their natural crystalline structure and non-magnetic quality make them suitable for construction, automotive, and aerospace. Also, the 300 series endures cracking and etching, unlike other grades.

The 300 series is an extraordinarily flexible and durable material. As an unfathomably solid substance, you can shape it into a huge swath of structures. Regardless of whether it’s the cutlery or the machine parts you utilize each day, you most presumably encountered the 300 series.

This steel aesthetically looks good and performs well. For this reason, the material makes the choice for quality street furniture. Considering its durability, it could address a satisfying expansion to our public spaces.

Since 300 series stainless steel is a compound out of blending chemicals and materials, engineers can control its attributes. Yaoyi provides a one-stop service to help you in choosing the type of stainless steel you need. Check out the list of 300 series grades in this section, and know their uses.

301 stainless steel is the one with a shiny surface and can resist atmospheric destruction. With this quality, it is highly utilized for interior decorations and exterior uses. Moreover, it is incredibly solid in force yet remains promptly doable at room temperature.

For projects not presented to saltwater, high temperatures or other high-corrosion conditions, grade 301 will likely be the right choice. Furthermore, this steel is the best if you need one with greater tensile strength.

This grade is a combination that contains higher carbon levels. Also, it contains comparative amounts of nickel and chromium. Regularly sold in spring and wire structures, grade 302 is principally utilized by the makers of cone-shaped pressure springs.

The 302 stainless steel is impervious to acids, solvents, and synthetics. You can often find it in spring structures inside machines utilized in kitchens, food manufacturing companies, clinical contexts and dairies.

Grade 303 is austenitic, non-magnetic stainless steel that is not solidified by heat treatment. It extraordinarily shows improved machinability while keeping up great mechanical and corrosion-safe properties.

Like other austenitic grades, 303 stainless steel exhibits brilliant sturdiness, albeit the sulfur lessens this a little. In line with this, manufacturers commonly use this in screws, gears, shafts, and many more.

Thin Stainless Steel Sheets Manufacturer

Among all the grades within 300 series stainless steel, grade 304 is the most popular. It contains around 18% chromium and 8% nickel. Just as offering great protection from corrosion and simplicity when welding, this product has amazing flexibility. What’s more, you can utilize it for a very wide scope of applications.

You’ll discover grade 304 utilized in pots, sinks, containers and sterile surfaces at home. The substance works well in cladding, street furniture, handrails, chemical plant apparatus, surgical tools and transport holders.

After grade 304, the 316 stainless steel is maybe the most utilized. The substance contains molybdenum, which provides the item additional protection from oxidation and corrosion. This quality makes it especially appealing to those hoping to utilize the item in chloride or marine conditions.

Furthermore, 316 stainless steel is durable. Yet, similarly, it has outstanding formability. These twin credits make it ideal for creating springs for the marine, gas and oil enterprises.

Unlike the other grades, the 317 stainless steel is not ideal for construction industries. However, it works best for projects that need greater corrosion resistance as compared to grade 316. For projects with high industrial pollution, hot climates, excessive salt exposure, grade 317 is the best to use. What’s more, it has a molybdenum content of 3% to 4%.

Uses of ASTM A240 Stainless Steel

The greatest contrast between the 300 series and the 400 series is the nickel content. The shortfall of nickel is a key marker that the alloy of stainless falls inside the 400 series. In its structure, the absence of nickel makes the 400 series less impervious to corrosion than the 300 series stainless steel.

All steel series are repellent to corrosion, and some are safer than others. Yet, another critical distinction between the two is how the 400 series has magnetic properties.

Regarding cost, the 300 series stainless steel regularly remains the most costly. The distinction in value goes back to the reason that the 400 series doesn’t have corrosion-resistant quality.

The application where the woven wire will be utilized suggests what alloy should be employed in terms of use. If the network is acquainted with brutal, destructive substances, the 300 series stainless steel must be applied.

Furthermore, you should use the 400 series stainless steel if your activity requires the utilization of magnetic material. You can likewise apply the 400 series when you are preparing non-destructive materials, like food particles.

Coilover Springs: Characteristics, Materials, and Applications

The 300 series stainless steel is a combination of metals that are more grounded and stronger when mixed. By adding and deducting different components to this stainless steel, engineers have had the option to make various assortments. Each has their attributes and employment.

The 300 series austenitic stainless steel is a flexible metal. You can use it for various things, particularly kitchen hardware. It is the material of decision for the food and refreshment industry. This series of steels is worthwhile because they don’t influence the food’s flavor. Furthermore, they are handily cleaned and disinfected to forestall bacterial defilement of the food and are durable.

The 300 series is widely utilized in cookware, winemaking, food processing and manufacturing, business kitchens, fermenting lager, and meat handling. Not only in the food industry, but you can also see this series in the kitchenware and utensils you use at home. This series of stainless steel has also made its way to the medical field. Its uses vary, yet usually, it exists in hypodermic needles, needle caps, and many more.

Furthermore, the 300 series stainless steel is also used in the automotive industry for making fuel rails, orifices, and automotive parts. Many experts in the industry applaud this series for its formability and versatility when used in the manufacturing process. You can also find this widely applied in the aerospace industry for producing helicopter, landing gears, and engine components.

If you’re thinking about when is the best time to use the 300 series stainless steel, you always need to assess the setup. Generally, the 300 series works best for projects that require the introduction of corrosive and harsh substances. This type of stainless steel is strong enough to withstand it all!

A Complete Guide to 316L Stainless steel

Yaoyi is a leading producer with long-lasting experience and knowledge of stainless steel coils that needs to be chosen to work for you. We can recommend and give the best possible product to the correct manufacturer of stainless steel coils by listening to your application and concerns. We may be able to work with your application and sector.

Stainless steel can both be confusing and an interesting subject to prying into. By understanding the existence and characteristics of different grades, you break into a technical aspect in the industry. Learning this information is what separates an efficient application from a possibly costlier and riskier usage.

If you’re looking for more information about SUS 301 stainless steel, please feel free to contact us. Yaoyi is your leading manufacturer of stainless steel. We deliver only the best quality of services and products.

Like gold tested in fire, the 300 series stainless steel can withstand high temperature and resists corrosion. It has many uses, which reached the extent that you may see it employed in almost everything around you. Its quality and durability made it the most extensively used material in various industries.

SUS 301 Stainless Steel: The Ultimate Guide